In the world of industrial manufacturing, pharmaceutical production, and commercial facilities, water is rarely just “H2O.” The raw water drawn from rivers, deep wells, or municipal supplies is a complex cocktail of dissolved minerals, suspended particulates, biological matter, and chemical compounds. For plant managers and process engineers, understanding the water purification working principle is not merely an academic exercise—it is the fundamental baseline for ensuring production quality, complying with environmental standards, and protecting expensive downstream machinery from scaling and corrosion.

Many procurement officers mistakenly believe that a single “magic filter” can solve all water quality problems. In reality, the water purification working principle relies on a “Multi-Barrier Approach”—a sophisticated chain of unit operations designed to strip away contaminants layer by layer, from visible mud to invisible ions.

This comprehensive guide moves beyond basic definitions to explore the physics, chemistry, and engineering logic behind the water purification working principle. We will examine how technologies like الترشيح الفائق (UF) و التناضح العكسي (RO) actually function, and how they are integrated into our complete Stark Water Treatment Plants to deliver consistent, high-purity water.

The Water Purification Working Principle Hierarchy: How a System is Built

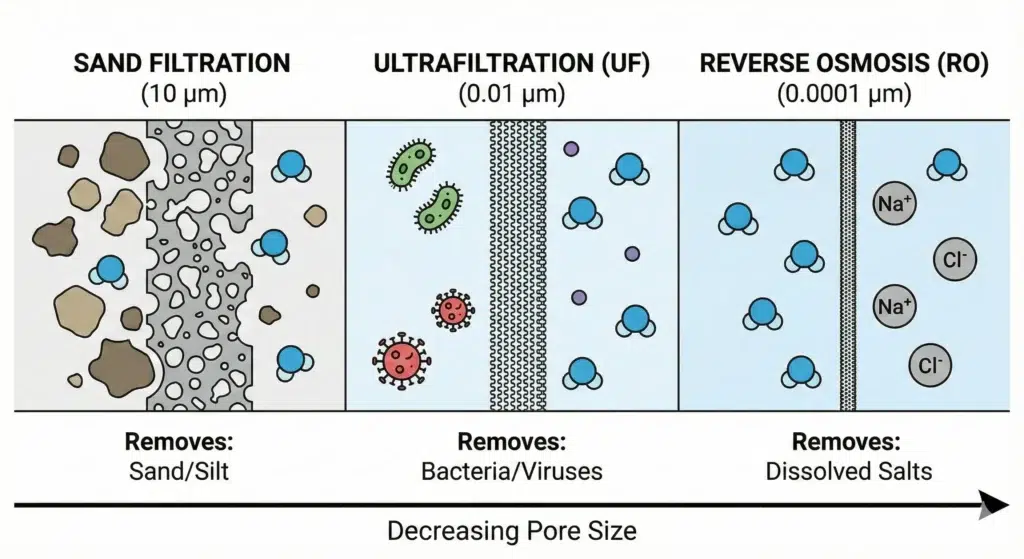

A robust water treatment system functions like a high-security clearance checkpoint. You cannot send dirty, turbid water directly into a high-precision nanoscale membrane; it would foul and clog instantly. Therefore, the water purification working principle is scientifically divided into three critical zones:

- Zone 1: Pre-treatment (The Bodyguards): Removes large solids, suspended matter, and hardness to protect the core system.

- Zone 2: Membrane Separation (The Core): Utilizing UF or RO to separate molecules and ions at a microscopic level.

- Zone 3: Post-treatment & Storage (The Polishing): Ensuring the water remains pure until the point of use.

At Stark Water, we pre-assemble these zones into skid-mounted, turnkey solutions. Whether you need a containerized mobile plant or a large-scale factory installation, you can view our full range of integrated systems here: View Industrial Water Treatment Plants & Systems.

Zone 1: Pre-treatment – The Foundation of the Water Purification Working Principle

The longevity of your expensive RO membranes depends entirely on the efficiency of your pre-treatment. If the water purification working principle of this stage fails, the entire plant fails. This stage relies on physical media filtration housed in robust pressure vessels.

1. Multimedia & Quartz Sand Filtration (Turbidity Removal)

Raw water often contains mud, rust, and colloids larger than 10 microns. We utilize Quartz Sand Filters أو Multimedia Filters (MMF) to physically trap these particles.

The Mechanism: As water flows downward through the graded sand bed, particles are trapped in the voids between grains. The system monitors the pressure drop (Delta P) and automatically performs a “Backwash” cycle to flush these trapped solids out to the drain.

2. Activated Carbon Filtration (Chemical Adsorption)

While sand removes solids, it cannot stop dissolved chemicals. Activated Carbon Filters utilize the vast surface area of carbon pores to adsorb Residual Chlorine, organic compounds (TOC), colors, and odors.

Critical Engineering Note: Chlorine is a strong oxidizer that can chemically destroy Polyamide (PA) RO membranes within hours. A properly sized carbon filter is the primary defense against this irreversible oxidation damage.

3. Water Softening (Ion Exchange Technology)

Hard water contains high levels of Calcium and Magnesium ions. If left untreated, these ions will precipitate as “scale” (Calcium Carbonate) on the membrane surface, blocking flow and disrupting the water purification working principle.

The Mechanism: Resin Softeners operate on Ion Exchange principles. The resin beads are charged with Sodium ions. As hard water passes through, the resin grabs the Calcium and releases Sodium.

Component Integration: The Role of Pressure Vessels

All these filtration media (Sand, Carbon, Resin) must be housed in tanks that can withstand continuous cyclic pressures of 100-150 PSI. For these pre-treatment applications, we utilize high-strength Stark Fiberglass (FRP) Tanks. Their composite structure provides superior corrosion resistance against brine and backwash water compared to standard steel tanks.

Zone 2A: Ultrafiltration (UF) – The Physical Sieve Working Principle

Ultrafiltration is a low-pressure membrane process that serves as an excellent pre-treatment for RO (replacing sand filters) or as a standalone purification method for surface water and mineral water production.

The Physics of UF

إن water purification working principle of Ultrafiltration is based on size exclusion. UF membranes feature a nominal pore size of approximately 0.01 microns. This acts as a definitive physical barrier.

- يزيل: Bacteria (99.99%), Viruses, Colloids, and significantly reduces the Silt Density Index (SDI).

- Passes: Dissolved salts, sugars, and beneficial minerals.

Why Choose UF?

Stark Water systems typically utilize Hollow Fiber membranes in an “Outside-In” or “Inside-Out” flow configuration. The primary advantage of UF is that it requires significantly lower energy than RO and retains beneficial minerals, making it the ideal technology for mineral water bottling plants.

Zone 2B: Reverse Osmosis (RO) – The Molecular Water Purification Working Principle

For applications requiring pure or ultrapure water—such as boiler feed, pharmaceutical production, or electronics manufacturing—removing bacteria is not enough. You must remove dissolved minerals (TDS). This is where Reverse Osmosis excels.

The Physics of Reverse Osmosis

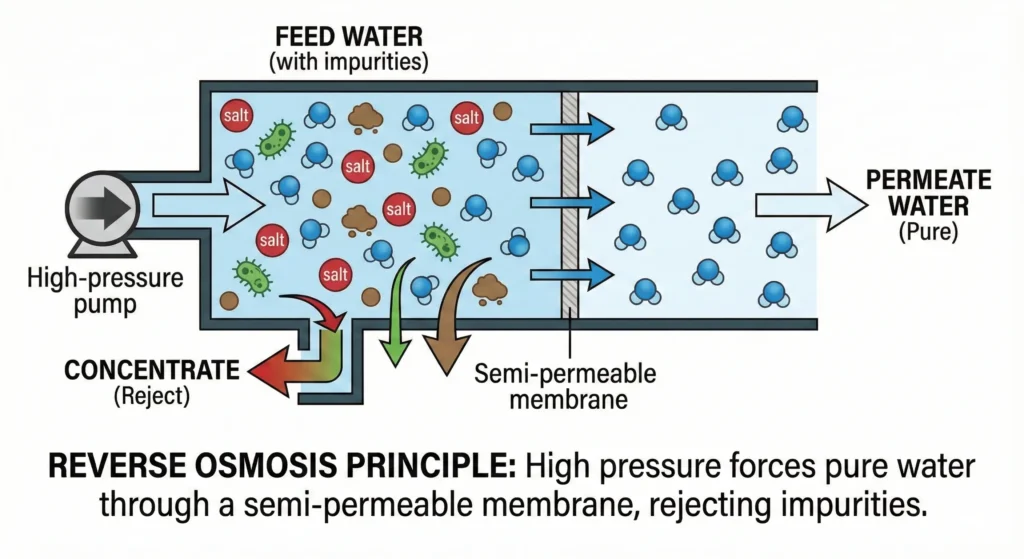

RO is the finest level of filtration available commercially. The membrane pore size is estimated at 0.0001 microns—a million times smaller than a human hair. This defines the core of the water purification working principle for desalination.

The Mechanism: In nature, osmosis moves water from a dilute solution to a concentrated one. In Reverse Osmosis, we use a High-Pressure Pump to force water against this natural osmotic pressure. The water molecules are pushed through the semi-permeable membrane, while contaminants are rejected and flushed out as a “Concentrate” or “Brine” stream.

What Does RO Remove?

- Dissolved Inorganics: Sodium, Chloride, Sulfates (Desalination rates >99%).

- Heavy Metals: Lead, Arsenic, Mercury, Cadmium.

- Micro-pollutants: Pesticides, antibiotics, and nitrates.

Because RO systems involve complex hydraulics, high-pressure pumps, and electrical controls, buying a pre-engineered system is crucial to avoid issues like cavitation and fouling. Explore our fully engineered RO solutions here: View Stark RO Water Treatment Plants.

Technical Comparison: UF vs. RO Technologies

Understanding the fundamental difference between these two core technologies is vital for selecting the right equipment for your facility’s specific water analysis.

| المعلمة | الترشيح الفائق (UF) | التناضح العكسي (RO) |

|---|---|---|

| دقة الترشيح | 0.01 Microns | 0.0001 Microns |

| Primary Target | Turbidity, Bacteria, SDI | TDS, Salts, Heavy Metals |

| Water Purification Working Principle | Physical Screening | Diffusion & Exclusion |

| Mineral Retention | Retains beneficial minerals | Removes >98% of minerals |

Zone 3: Post-Treatment & Sanitary Storage

Once water passes through the RO membrane, it is in a “hungry” state (high purity, low TDS). It becomes highly aggressive and can easily absorb CO2 from the air (lowering pH) or become contaminated by airborne bacteria. Therefore, the water purification working principle extends to how you store the product.

The Importance of Sanitary Storage

To maintain the purity achieved by the RO system, the storage vessel must be as clean as the water itself. Standard plastic tanks often have rough internal surfaces that can harbor biofilm.

For RO permeate, pharmaceutical-grade water, and food-grade applications, we integrate Polished Stainless Steel Tanks. These vessels feature smooth internal surfaces (Ra < 0.4µm) and are equipped with aseptic breathers to prevent bacterial adhesion. You can view the technical specifications for these specialized storage units at our tank division: Stark Stainless Steel Vessels.

Maintenance: The Key to System Longevity

Even the best-engineered system requires maintenance. A fundamental part of the water purification working principle is the recovery of membrane performance.

- CIP (Clean-In-Place): Periodically circulating acid or alkaline cleaning solutions to remove scale and organic fouling from RO membranes.

- Backwashing: Reversing the flow in Sand/Carbon filters to expand the media bed and flush out trapped sediments.

Stark Water systems are designed with user-friendly control panels to automate many of these maintenance tasks, ensuring your plant runs at peak efficiency with minimal downtime.

Conclusion: Building Your Custom Solution

إن water purification working principle is a science of separation, requiring a harmonious integration of physical filtration (MMF/UF) and molecular separation (RO). No single component can do it all; it is the synergy of the pre-treatment, the membrane core, and the storage system that delivers the results.

At Stark Water, we don’t just sell components; we design complete process flows. From calculating the correct filtration velocity for your sand filters to sizing the high-pressure pumps for your RO skid, we deliver turnkey reliability.

Ready to upgrade your facility’s water infrastructure?

Stop guessing with mismatched components. Explore our Complete Water Treatment Plant Solutions and let our engineering team build a system tailored to your specific raw water analysis.