4040 vs 8040 ro membrane — this guide compares size, permeate tube, housing compatibility, staging, flux, and pressure windows so you can pick the right element for BWRO, SWRO, or commercial RO skids.

Browse RO Membranes Open RO Sizing Calculator

Quick Answer

- 4040: 4″ x 40″ element with 0.75″ permeate tube, compact vessels, lower capital cost. Best for light commercial, laboratories, food service, and pilot trains at approximately 0.2 to 3 m3/h.

- 8040: 8″ x 40″ element with 1.125″ permeate tube, industrial vessels. Preferred for municipal and industrial BWRO or SWRO where higher productivity and fewer housings are required.

4040 vs 8040 ro membrane — key differences

The phrase 4040 vs 8040 ro membrane usually means comparing element size, permeate-tube interface, vessel count, and achievable flux at the same water quality. A 4040 train minimizes capex and is easy to service at small flows, while an 8040 train reduces the number of vessels and fittings and delivers higher productivity for municipal or industrial plants. When footprint, energy, and total cost of ownership matter, the 4040 vs 8040 ro membrane choice is driven by staging (2:1, 3:2, 4:2), recovery targets, and pretreatment quality.

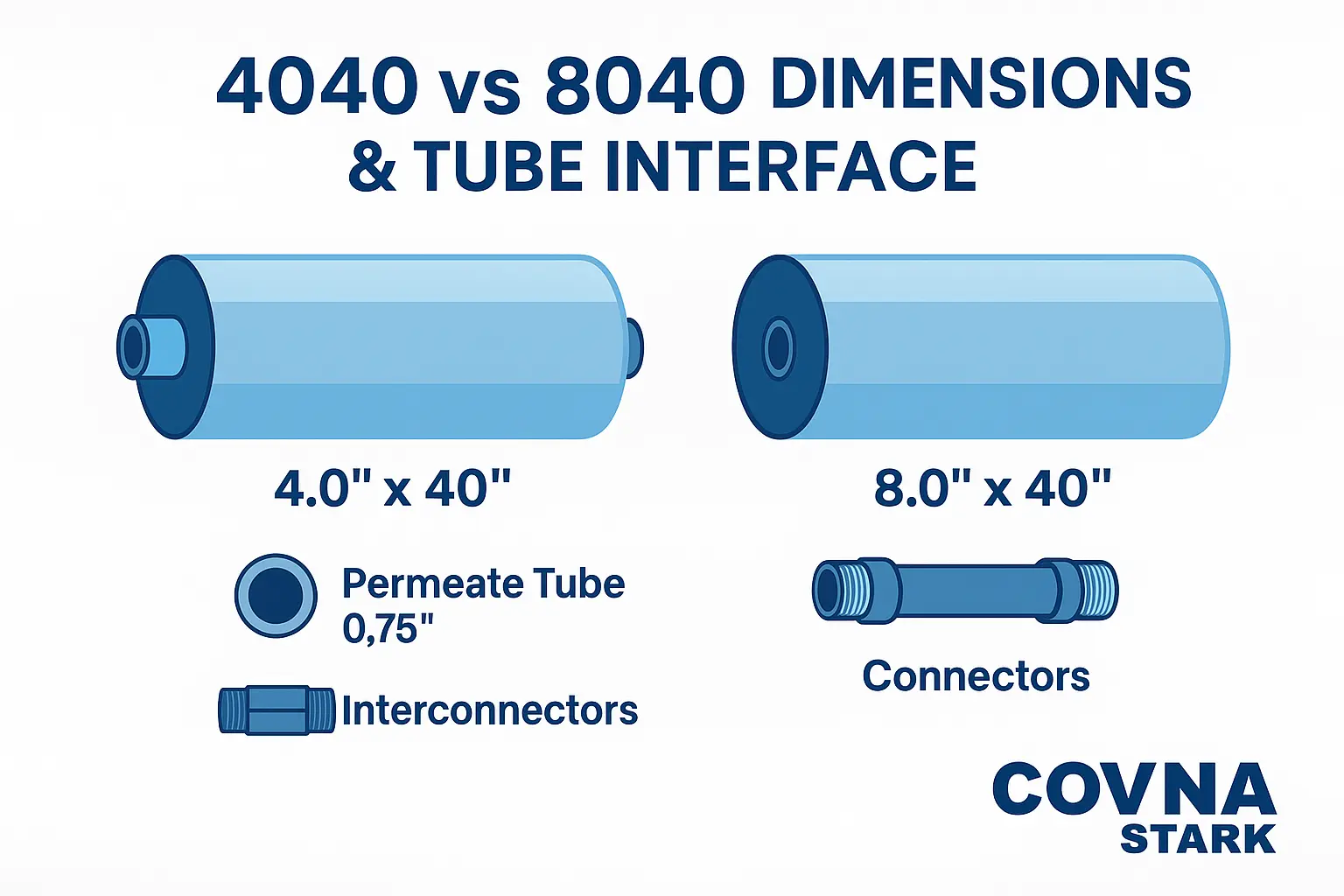

Dimensions and Interfaces

| Item | 4040 | 8040 |

|---|---|---|

| Element Size | 4.0″ x 40″ | 8.0″ x 40″ |

| Permeate Tube (ID) | approximately 0.75″ | approximately 1.125″ |

| Interconnectors | Short couplers; usually one element per 4″ vessel | Couplers between elements; multiple per 8″ vessel |

| Brine Seal Orientation | Seal faces the concentrate side; follow vessel flow arrow | Same; confirm stage flow direction before insertion |

Housing Compatibility and Staging

- 4040 vessels: commonly one element per vessel. End caps may be clamp ring or threaded depending on brand.

- 8040 vessels: one to seven elements per vessel. Follow manufacturer torque values and support or strap requirements on the high-pressure side.

- Staging: Small 4″ systems often use 1:1 or 2:1. Industrial 8″ trains commonly use 2:1, 3:2, or 4:2 to balance recovery and cross-flow velocity.

This guide helps you pick the right 4040 vs 8040 ro membrane configuration for BWRO or SWRO.

Use normalized data when comparing 4040 vs 8040 ro membrane performance at different temperatures.

See our step-by-step 4040 vs 8040 ro membrane replacement checklist to reduce downtime.

Design example: small café vs. industrial BWRO

A coffee shop needing 0.6 m3/h can run a single-train 4040 system with 1:1 staging at 60–65% recovery, cartridge filtration, and a carbon block to protect the membrane. The same water quality scaled to 20 m3/h favors an 8040 train with 3:2 staging to maintain cross-flow and keep per-stage ΔP within limits. In both cases, normalized permeate flow is tracked daily; when rejection drops 2–3% or normalized flow declines 15–25% and cleaning no longer recovers performance, plan a membrane change. This illustrates how the 4040 vs 8040 ro membrane decision is a system-level trade-off among productivity, vessel count, energy, and maintenance access.

Design Windows

Recovery and Cross-flow

BWRO total recovery is typically 45 to 75 percent using multi-stage design. SWRO is typically 35 to 50 percent. Maintain cross-flow to prevent deposition.

Pressure and Differential Pressure

4040 BWRO is commonly 8 to 16 bar. 8040 BWRO is commonly 10 to 20 plus bar. SWRO is commonly 50 to 70 plus bar. Keep per-stage differential pressure within supplier limits, often less than 1.0 to 1.5 bar.

Temperature Correction

Permeate flow increases with temperature. Compare performance using normalized, temperature-corrected data.

Sizing and Flux

Achievable flux (LMH or GFD) depends on pressure, temperature, salinity, recovery, and the specific membrane model. Keep normalized permeate flow within supplier recommendations and maintain cross-flow through appropriate staging.

- 4040: unit capacities are often approximately 0.2 to 1.5 m3/h per skid depending on water quality and model. Modular expansion is straightforward.

- 8040: larger area per element provides significantly higher output per vessel and fewer vessels for the same capacity. Suitable for medium and large BWRO and SWRO systems.

For quick estimates, use the RO sizing calculator.

When to Choose 4040 vs 8040

| Scenario | Prefer 4040 | Prefer 8040 |

|---|---|---|

| Start-up, pilot, or small commercial | Low capital cost, flexible layout, easy servicing | Not typically required |

| Municipal or industrial BWRO | Possible for small flows | Fewer vessels and fittings, better footprint and energy |

| Seawater RO (SWRO) | Used mainly for pilot systems | High-pressure industrial systems with multi-stage design |

| Maintenance access | Simple handling and common spare parts | Requires proper tools and stricter safety procedures |

Installation and Safety Notes

- Verify element model, interfaces, and interconnectors. Insert with the brine seal facing the concentrate side.

- Tighten end caps evenly to the specified torque. Repressurize slowly, leak-check at low flow, then ramp to design.

- For shutdowns longer than 24 to 48 hours, apply preservation. Perform CIP (acid, alkaline, or biological) as required.

See the full step-by-step procedure: RO membrane replacement.

الأسئلة الشائعة

Is an 8040 always more efficient than a 4040?Can I mix 4040 and 8040 in the same train?What about housing and end caps?

Get a Model Match and Quote

Send feed TDS and temperature, target permeate flow, and design recovery. We will recommend 4040 or 8040 models, vessels, and interconnectors.

Select 4040 or 8040 Membranes See Complete RO Systems

References: DuPont FilmTec RO/NF Technical Manual | AMTA Fact Sheet – Cleaning in Place (CIP)