This guide explains the dewatering screw press working principle used in municipal and industrial sludge treatment. You’ll learn how the machine moves sludge through flocculation, thickening, dewatering and discharge zones; how key parts work together; and how to size, operate and maintain a screw press for stable cake solids and high capture rate. Use this page as an engineering primer—always follow your OEM manual for safety limits and commissioning.

What it is & where it fits

A dewatering screw press (also called a multi-disc screw press or screw-type dehydrator) is a low-speed, continuous device that consolidates sludge solids into a stackable cake while returning clarified filtrate to the headworks or upstream process. It commonly follows gravity thickening, DAF, secondary clarifiers, or equalization tanks, and precedes cake handling steps such as conveyors, bins and dryers.

- Typical applications: municipal WWTP, food & beverage, pulp & paper, textile/dyeing, chemical and oily sludges.

- Why choose it: low energy and wash-water demand, compact footprint, simple guarding and low noise compared with belt presses and centrifuges.

Related hardware for tanks, guards and manifolds can be found in our منتجات الفولاذ المقاوم للصدأ و accessories catalogs.

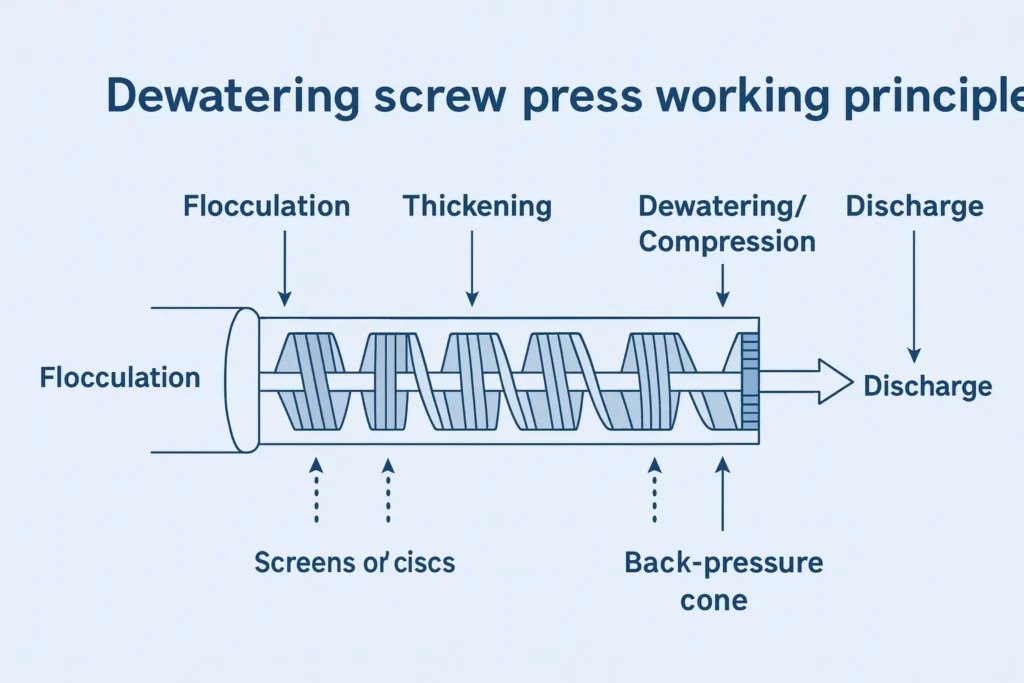

Dewatering screw press working principle

A screw press transports conditioned sludge through a cylinder where the pitch of the screw decreases and the drainage path narrows. Gravity and compression expel water through slots or discs while solids advance toward the discharge under a controlled back-pressure.

1) Flocculation zone

Polymer (dry or emulsion) is dosed and mixed with feed sludge to build strong flocs. Key controls are polymer type/charge, solution aging, dilution water quality, mixing shear and residence time. Good flocs resist shear and drain rapidly in the next zones.

2) Thickening / gravity drainage zone

The rotating screw gently conveys sludge while free water drains by gravity through screen slots or gaps between fixed and moving discs. Speed is kept low to preserve flocs and minimize carryover of fines.

3) Dewatering / compression zone

Screw pitch becomes shorter and the drainage path narrows. Resistance increases and a back-pressure cone or adjustable outlet creates the pressure needed for additional water removal. Spray bars clean screens/discs to maintain permeability.

4) Discharge & filtrate handling

Cake is pushed through the outlet and drops to a conveyor or bin. Filtrate is collected under the machine and returned to the headworks or upstream tank. Provide odor capture/venting if needed.

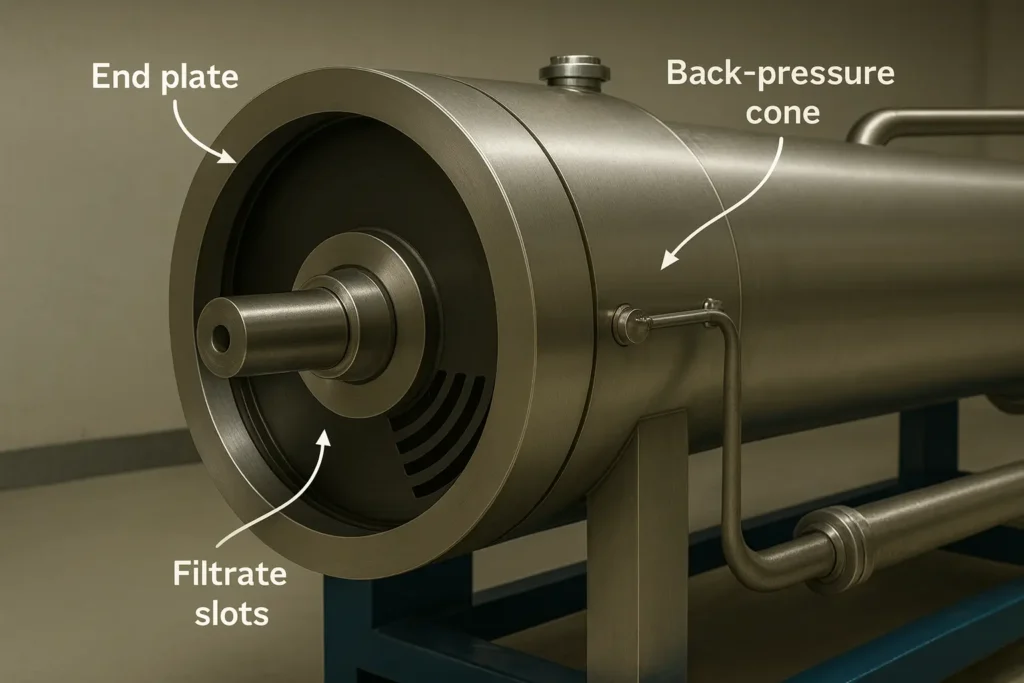

Key parts & materials

- Screw & shaft: low speed, abrasion-resistant; flight hardfacing optional for sandy sludge.

- Screen / multi-disc stack: stainless steel (SS304/316L). Disc design self-cleans by relative motion.

- Back-pressure cone & end plate: sets outlet resistance and cake dryness.

- Drive & gearbox: provides high torque at low rpm; include overload protection.

- Spray system: intermittent cleaning; optimize to reduce water use.

- Polymer station: make-up tank, eductor or dosing pumps, aging and dilution controls.

- Instrumentation: feed flow, torque/load, cake solids (spot check), filtrate turbidity/flow, wash-water flow.

For tanks, guards, support frames and hygienic manifolds, see our stainless steel range.

Performance metrics & what drives them

- Feed solids (%DS): typical 0.5–4% after clarifiers or DAF.

- Cake solids (%DS): target range depends on sludge—often 18–30% for municipal; higher for fibrous/oily sludges with good conditioning.

- Capture rate (%): 90–98% when polymer type/dose and mixing are dialed in.

- Throughput (kg-DS/h): governed by screw size, speed, drainage area and back-pressure.

- Specific energy (kWh/t-DS) & wash water (L/h): typically much lower than centrifuges; optimize by intermittent cleaning and correct rpm.

Key drivers: floc quality, screen/slot condition, flight pitch profile, rpm and outlet back-pressure, sludge temperature and composition .

Sizing & selection quick rules

Start from the dry-solids load and then check hydraulics and capture targets:

DS load (kg-DS/h) = Feed flow (m³/h) × Feed solids (%DS) × 10

- Select screw size to handle peak DS load with 10–20% margin.

- Ensure adjustable rpm, back-pressure and spray logic to cope with feed swings.

- Choose multi-disc types for low energy and oily/fibrous tolerance; choose heavy-duty screen types for higher compression needs.

- Polymer station must deliver stable concentration and aging; confirm dilution water quality.

Need help converting flow and %DS into a model shortlist? Upload your data (flow, %DS, target cake %, expected capture) for a quick sizing note.

Controls & routine O&M

Control logic

- Flow-paced polymer dosing → floc mixer → screw rpm/back-pressure trim to keep torque within band.

- Intermittent screen cleaning based on time or filtrate turbidity/pressure.

- Start-up: dosing & mixing first, then feed, then ramp rpm; Shutdown: stop feed, flush/clean, release back-pressure, stop screw.

Maintenance

- Inspect discs/screens; replace worn or plugged sections.

- Check spray nozzles and optimize intervals to cut water use.

- Grease bearings per OEM; monitor gearbox oil and seals.

- Verify guards/doors, odor ventilation and spill containment.

Troubleshooting

| Symptom | Likely causes | First checks |

|---|---|---|

| Cake too wet | Floc weak, rpm too high, back-pressure too low, feed %DS too low, over-washing | Jar test polymer, reduce rpm, raise back-pressure gradually, trim wash interval |

| Filtrate cloudy / low capture | Wrong polymer type/charge, over-shear, worn screens/discs | Re-screen jar tests, reduce mixer shear, inspect slots/discs |

| High torque / blockage | Fibers/strings, grit, back-pressure too high, sudden feed surge | Clear debris, reset outlet, stabilize feed, check overload protection |

| Spray water excessive | Clogged nozzles, poor cycle control, unnecessary continuous washing | Clean nozzles, switch to intermittent, use filtrate as make-up where allowed |

Screw press vs. belt press vs. centrifuge

| Criterion | Screw press | Belt press | Centrifuge |

|---|---|---|---|

| Energy | Low | Low–Medium | Medium–High |

| Wash water | Low (intermittent) | Medium–High | None |

| Noise | Low | Low–Medium | High |

| Cake %DS | 18–30% typical | 16–28% typical | 20–35% typical |

| Polymer demand | Low–Medium | Medium | Medium–High |

| Maintenance | Low; periodic screen/disc care | Belts/rollers/alignments | High-speed bearings/seals |

| البصمة | Compact | Large | Compact |

Choose based on site constraints and total OPEX; pilot testing is recommended for borderline sludges.

Typical applications & compliance notes

- Municipal primary/secondary sludge, digested sludge.

- Food & beverage: slaughter, starch, brewing, dairy.

- Pulp & paper, textile/dyeing, chemical/oily sludge.

- Compliance: filtrate return point, odor control, noise and enclosure; local disposal rules for cake handling.

قراءة الخلفية: Water Environment Federation resources و EPA NPDES overview.

Purchasing checklist (BOM)

| Item | Spec notes | Where to buy |

|---|---|---|

| Main screw press | Model size, screen/slot or disc material, rpm range, outlet control, guard/enclosure | طلب عرض أسعار |

| Polymer station | Dry or emulsion type, make-up/aging, dilution and dosing pumps | Accessories |

| Mix tank & floc mixer | SS304/316L, residence time, low-shear impeller | Stainless steel |

| Pumps & valves | Feed, wash water, filtrate, cake handling auxiliaries | Accessories |

| Instrumentation | Flow, torque, turbidity, level; interlocks and local HMI | Accessories |

| Platform & enclosure | Wash-down duty, ventilation/odor capture | Stainless steel |

الأسئلة الشائعة

What polymer is used for a dewatering screw press?

Cationic PAM (dry or emulsion) is most common. Grade and dosage depend on sludge type; confirm by jar tests and optimize dilution/aging.

How dry can the cake get?

Municipal sludges often reach 18–30% DS with good conditioning; fibrous or oily sludges may achieve higher values.

Does a screw press need wash water?

Yes, to keep screens or discs clean. Use intermittent cycles tied to turbidity or pressure to minimize consumption.

What is a typical capture rate?

90–98% when polymer chemistry, mixing and rpm/back-pressure are tuned; verify with periodic filtrate TSS tests.

Multi-disc screw press vs. conventional screw press?

Multi-disc adds self-cleaning discs for steady permeability at low rpm/energy; conventional screen types may achieve higher compression on certain sludges.

Next steps: size your screw press in 24 hours

Upload feed flow, %DS, expected swings, target cake %, and any space or noise limits. We’ll return a sizing note, BOM draft and O&M checklist.

Stark Water Engineering Team — sludge dewatering design, pilots & commissioning