This engineering guide explains how industrial users can treat كبريتيد الهيدروجين في مياه الآبار (H2S) using chlorination → contact tank → catalytic filtration → activated carbon. You’ll get dosing formulas, CT sizing, backwash requirements, safety notes, and a practical BOM. Focus: commercial/industrial wells feeding hotels, schools, plants, farms and campsites.

1) What H2S Is & Why It Matters

Hydrogen sulfide (H2S) is a dissolved gas frequently found in groundwater wells. It causes the familiar “rotten-egg” odor, black stains, and can accelerate corrosion. In industrial settings it also interferes with downstream processes and customer experience. Unlike iron or manganese that form solids easily, H2S is volatile and benefits from oxidation with contact time before filtration.

2) Diagnose Before You Design

- Measure: H2S (odor/field kits), Fe, Mn, pH, temperature; note iron bacteria or slime.

- Flows: design & peak (m³/h or gpm); available backwash flow and drain capacity.

- Site constraints: chemical handling policy, venting, space, electrical, discharge permits.

Tip: If iron bacteria are present, plan a shock chlorination and thorough cleaning before commissioning the new system.

3) Proven Process Trains (Industrial)

- Air Injection (AIO) → Catalytic Media — works on light odor but is less stable for high H2S or iron bacteria.

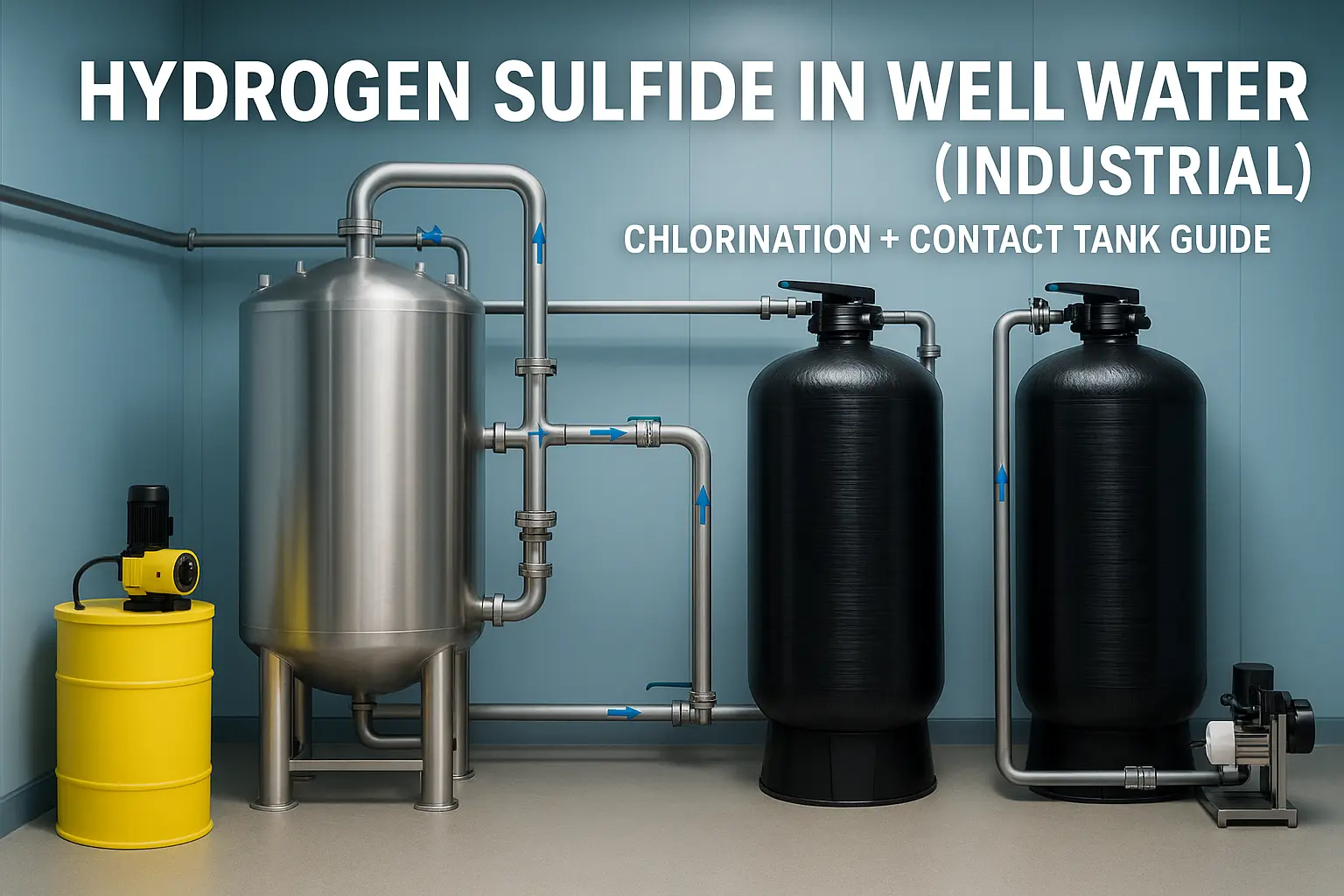

- Chlorination → Contact Tank → Catalytic Filter → GAC — the most robust route for كبريتيد الهيدروجين في مياه الآبار, also controls iron bacteria.

- Advanced oxidation (e.g., peroxide/ozone) — specialty cases or high loads; often combined with a contact tank and catalytic media.

4) Quick Selection Matrix

| Condition | Recommended train | Key notes |

|---|---|---|

| Mild odor, low Fe/Mn, stable feed | AIO (air) → catalytic media | Lowest maintenance; verify backwash capacity |

| Moderate–high H2S or iron bacteria | Chlorination → contact tank → catalytic filter → GAC | Most stable; adds disinfection and odor control |

| Very high load or special constraints | Peroxide/ozone + contact tank → catalytic filter → GAC | Engineer case-by-case; ensure venting and safety |

5) Chlorination Dosing & CT Sizing

Goal: maintain a small free-chlorine residual (~0.2–0.5 mg/L) at the contact-tank outlet while providing ~5–10 minutes of effective contact time (CT). Adjust per local regulation and downstream processes.

5.1 Dosing formula (sodium hypochlorite)

L/h of NaOCl ≈ (Required mg/L as Cl2 × Flow m³/h × 1000) ÷ (Available chlorine of solution, mg/L)

Example: dose 2 mg/L at 10 m³/h using ~10% NaOCl (~100,000 mg/L) → 0.2 L/h (add safety margin for demand swings).

5.2 Contact time (CT) calculation

CT (min) = (Effective volume of contact tank, L) ÷ (Flow, L/min)

- Use a baffled stainless-steel contact tank to prevent short-circuiting; include venting for gas release.

- Provide isolation/bypass and a sampling port at the outlet to check residual and odor removal.

6) Catalytic Filtration & Backwash

- Media: Katalox Light / Greensand+ / MnO2-rich media; typical service ~8–12 gpm/ft², backwash ~12–15 gpm/ft².

- Design with differential-pressure gauges; backwash until clear. If pump/drain limit backwash, parallel smaller vessels or add a dedicated backwash pump.

- Keep pH in a favorable window (near neutral or slightly alkaline) for oxidation and media performance.

7) Carbon Polishing & Final Steps

- GAC removes residual chlorine and improves taste/odor after catalytic filtration.

- For potable uses, add UV disinfection per code; verify residuals and absence of odor before service.

- Document startup baseline: residual at contact-tank outlet, ΔP across filters, flow and ORP.

8) Materials, Safety & Instrumentation

- Vessels: SS304/316L contact tanks, FRP/SS pressure filters with distributors and automatic valves.

- Dosing: metering pump + solution tank + static mixer; add ORP/free-chlorine monitor at the contact-tank outlet.

- Safety: ventilation, secondary containment, eyewash/shower, chemical SOPs and staff training.

Related products:

9) Bill-of-Materials (BOM) Template + CTA

- Dosing skid: metering pump (0–4 L/h adjustable), solution tank, isolation valves, calibration column

- Contact tank: baffled SS tank with vent and sampling port; sized for 5–10 min CT

- Catalytic filter: FRP/SS vessel, media loading per spec, automatic backwash valve, ΔP gauges

- Polishing: GAC filter; optional UV for potable applications

- Instrumentation: ORP/free-chlorine, flow meters, pressure gauges; logging in PLC/HMI

- Docs: P&ID, layout, start-up & commissioning checklists

10) FAQ

Is air injection enough for hydrogen sulfide in well water?

It can help when odor is mild and water is stable, but chlorination with contact time is more robust for moderate–high H2S and iron bacteria.

How much contact time do I need?

As a practical starting point, design for ~5–10 minutes of effective CT in a baffled tank and verify performance on site. Adjust per local regulation and downstream processes.

Do I always need activated carbon?

Recommended after chlorination to remove residual chlorine and improve taste/odor; it also protects downstream users.

What if my pump can’t supply enough backwash?

Use smaller parallel vessels with staggered backwash, add a dedicated backwash pump, or rely more on chemical oxidation with adequate CT to reduce the load per vessel.

11) References (External)

Stark Water Engineering Team