مقياس التدفق البلاستيكي والأكريليكي (مقياس دوار) | ستارك ووتر

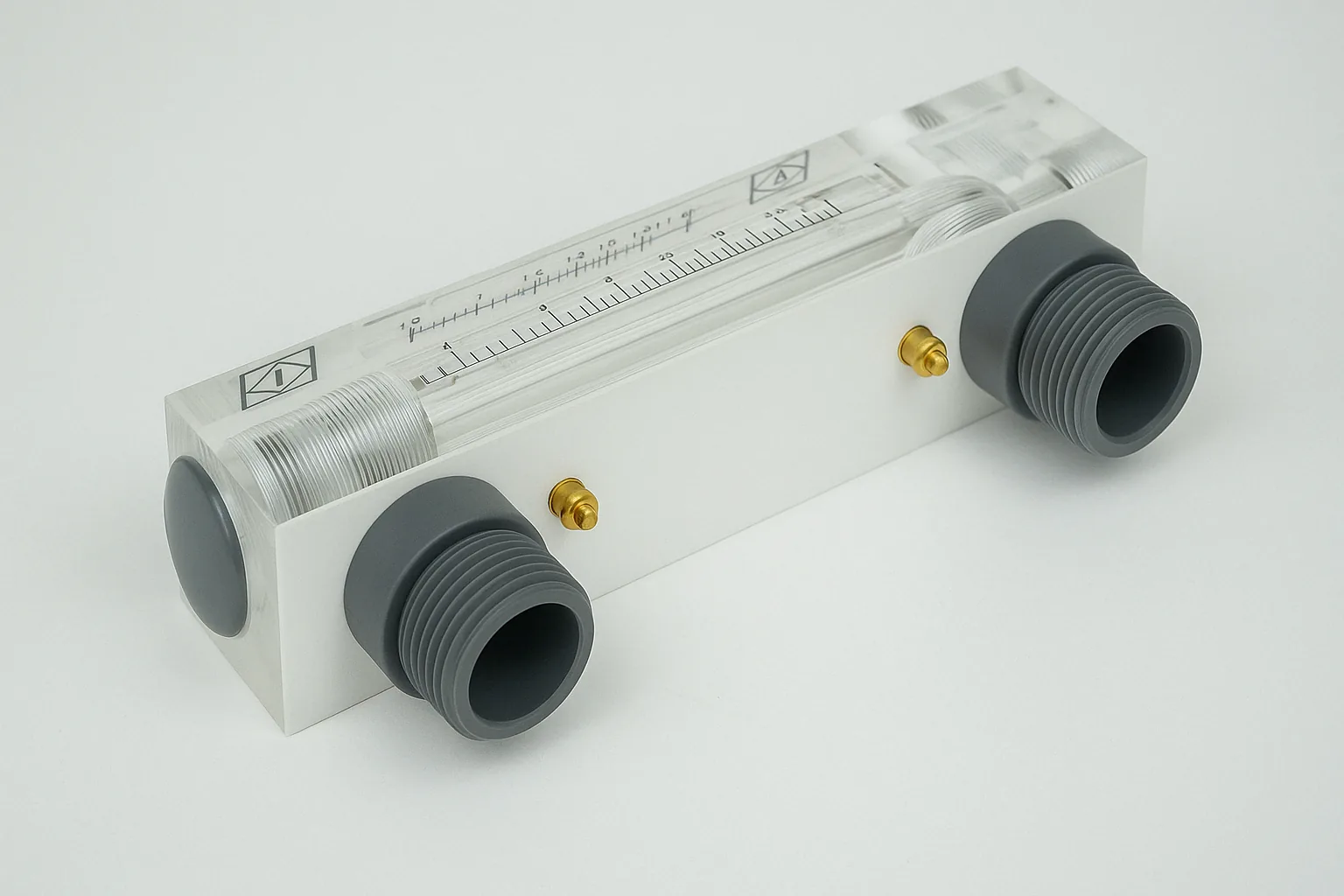

Plastic acrylic flow meter (rotameter) by STARK provides clear, accurate indication of water and air flow for RO skids, dosing lines, and HVAC loops.

وصف المنتج

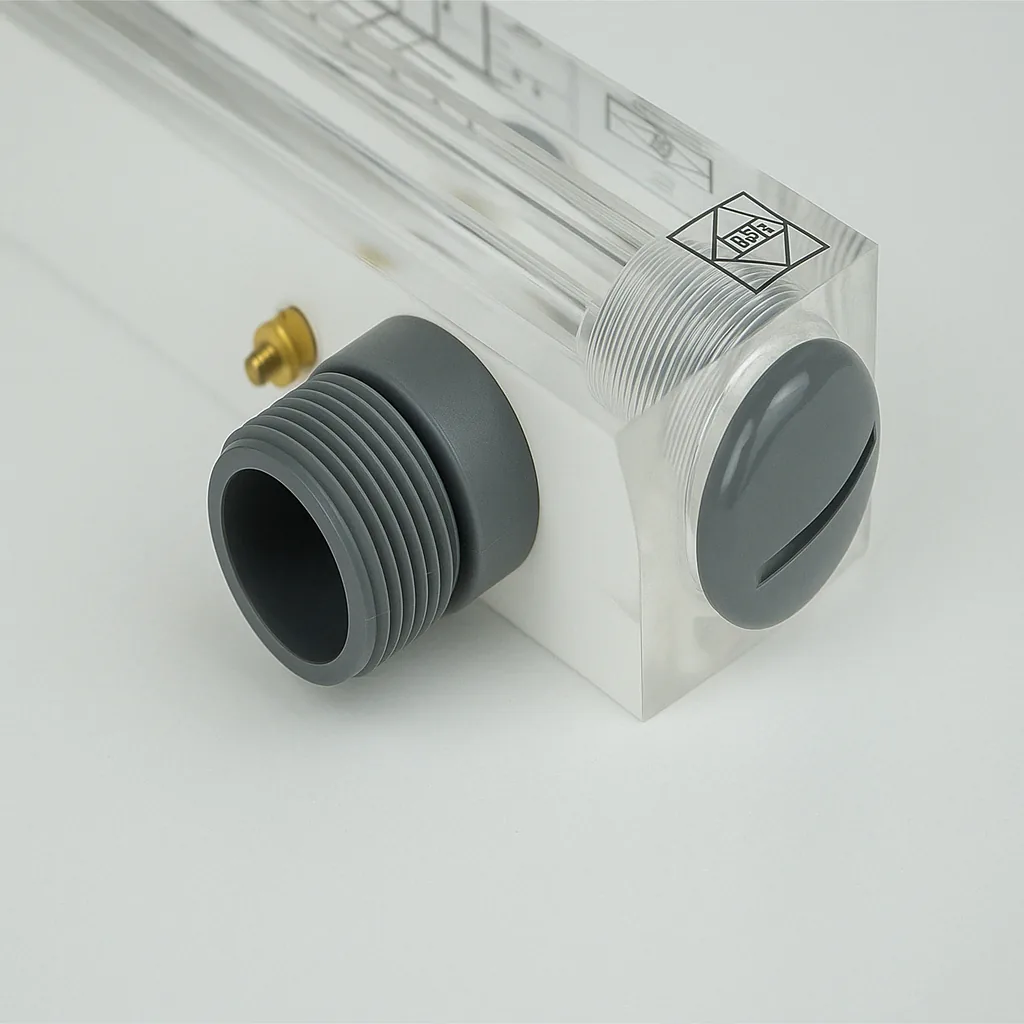

Standard bodies are PVC or PP with a clear acrylic tube for excellent readability and impact resistance. Units include stainless-steel or optional plastic floats (range-dependent), O-ring seals, and union end connections for quick installation and service. Calibration can be supplied in L/h, L/min, m³/h or GPM to suit project specifications.

- Clean scale printing with protective window; optional dual-scale (water/air)

- Compact form factor for panel or in-line mounting

- Good chemical compatibility for typical water-treatment fluids

- Each unit tested for leakage and scale accuracy before shipment

معلمة المنتج

| Measurement Principle | Variable area (rotameter) with float in tapered acrylic tube |

|---|---|

| Media | Water or air (other compatible liquids/gases on request) |

| Body / Tube | PVC or PP body; clear acrylic tube |

| Float | Stainless steel / PTFE / PVC (per flow range) |

| Seals | EPDM standard; FKM (Viton) optional |

| Nominal Sizes | DN15–DN50 (1/2″–2″) typical; others on request |

| Connections | Union/threaded or solvent-weld; BSP/NPT available |

| Flow Ranges (water @20 °C) | Approx. 10–100 L/h up to 1–10 m³/h (model-dependent) |

| Accuracy | ±4% of full scale (typical rotameter accuracy) |

| Max Pressure | 0.6–1.0 MPa depending on size and material |

| Max Temperature | 0–60 °C (consult STARK for higher or chemical service) |

| التركيب | Vertical installation, flow from bottom to top |

| الامتثال | Manufactured under STARK QA; pressure/leak tested |

Note: Final BOM (tube length, float material, scale units, and end connections) will be confirmed after your process data sheet is reviewed.

الصناعة المطبقة

- Reverse osmosis skids — permeate and concentrate monitoring

- Sand/carbon filters — backwash and rinse flow checks

- Chemical dosing systems — coagulant/antiscalant lines

- Cooling water & HVAC loops — visual flow confirmation

- Compressed air distribution — branch line balancing

- Laboratory & pilot plants — quick setup and verification

الميزة الأولى

Advantage 1 — Clear, Reliable Indication

- High-clarity acrylic tube with printed scale and reference pointer

- Simple mechanical design — no power supply required

- Union ends for fast installation and maintenance

- Multiple scale options (L/h, L/min, m³/h, GPM) and custom logo

الميزة الثانية

Advantage 2 — Robust Materials & Support

- PVC/PP body and corrosion-resistant wetted parts

- EPDM or FKM seals to match your chemical conditions

- Factory leakage/accuracy testing and spare parts availability

- Global technical support and fast lead time from STARK

المنتجات ذات الصلة

منتجات ذات صلة

الأسئلة الشائعة

س1: ما المدة التي يستغرقها نظام التناضح العكسي؟

يعتمد عمر نظام التناضح العكسي على جودة المياه والصيانة. عادةً ما يدوم الغشاء من 2-3 سنوات، بينما يمكن أن يدوم النظام نفسه لأكثر من 10 سنوات مع العناية المناسبة.

س2: هل يمكن تخصيص النظام بناءً على ظروف المياه المختلفة؟

نعم، جميع أنظمتنا قابلة للتخصيص بالكامل. نقوم بتحليل تقرير المياه الخاص بك واحتياجات التطبيق قبل تقديم حلول مصممة خصيصًا.

س3: ما هي المعايير التي تتوافق معها معدات STARK؟

تتوافق منتجاتنا مع معايير CE وISO 9001، ويمكن تصميمها لتلبية لوائح إقليمية أو معايير صناعية محددة عند الطلب.

س4: ما هو وقت تسليم أنظمة STARK RO؟

يتم شحن الأنظمة القياسية في غضون 7-15 يومًا. بالنسبة للطلبات المخصصة، قد تمتد المهلة الزمنية إلى 20-25 يومًا حسب درجة التعقيد.

السؤال 5: هل تقدمون الدعم الفني أو إرشادات التثبيت؟

نعم. نحن نقدم وثائق فنية كاملة، وإرشادات عن بُعد عبر الفيديو، ويمكننا إرسال مهندسين دوليًا عند الطلب.

س6: ما الذي يتضمنه عرض أسعارك؟

يشمل عرض أسعارنا نظام التناضح العكسي الكامل، ولوحة التحكم، والمضخات، ووحدات المعالجة المسبقة، وجميع التجهيزات اللازمة. ويمكن تضمين أدوات التركيب وقطع الغيار عند الطلب.