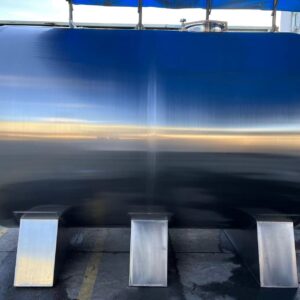

تدفئة مخصصة 316 خزان مياه من الفولاذ المقاوم للصدأ 316 خزان مياه معقم من الفولاذ المقاوم للصدأ

Achieve unparalleled purity and precise temperature control with Stark Water’s Customized Heating 316 Stainless Steel Water Tank. This sterile insulation water tank, crafted from premium 316 stainless steel, is custom-engineered for demanding industrial applications requiring hygienic storage and accurate thermal management of sensitive liquids.

وصف المنتج

In industries where product integrity, hygiene, and precise temperature control are non-negotiable—such as pharmaceuticals, biotechnology, and specialized food & beverage production—the quality of liquid storage tanks is paramount. The Stark Water Customized Heating 316 Stainless Steel Water Tank is meticulously engineered to meet these stringent demands, offering a superior solution for storing highly sensitive or temperature-critical liquids under sterile conditions.

The Apex of Material Science: 316 Stainless Steel Water Tank for Unrivaled Purity

The defining feature of this product is its construction from premium 316 stainless steel. While 304 stainless steel offers good general corrosion resistance, 316 stainless steel (specifically 316L for low carbon content, which improves weldability and resistance to intergranular corrosion) provides significantly enhanced resistance to chlorides, acids, and other aggressive chemicals. This makes our 316 stainless steel water tank uniquely suited for storing purified water, pharmaceutical ingredients, sterile solutions, and various process liquids where corrosion can lead to product contamination or material degradation. Its inert nature ensures no leaching into the stored liquid, guaranteeing the highest levels of purity and hygiene. The smooth, non-porous surface of 316 stainless steel actively inhibits microbial adhesion and facilitates thorough cleaning-in-place (CIP) and sterilization-in-place (SIP) processes, crucial for maintaining aseptic conditions.

Customized Heating & Sterile Insulation Water Tank Design

This is more than just a storage vessel; it’s a precisely controlled environment. The tank features fully customized heating capabilities, which can be integrated via heating jackets (dimple, coil, or full jackets for efficient heat transfer), internal heating coils, or electric heating elements. This allows for accurate temperature maintenance, pasteurization, controlled reactions, or prevention of viscosity changes for sensitive products. Complementing the heating, the tank is designed as a sterile insulation water tank. It incorporates high-performance insulation materials (such as polyurethane foam or mineral wool), meticulously clad in an outer stainless steel shell. This insulation minimizes heat loss or gain, drastically reducing energy consumption and ensuring stable temperatures for extended periods. The sterile design principles, including aseptic connections, polished internal finishes, and complete drainability, prevent microbial contamination, safeguarding product integrity from purification through storage.

Bespoke Engineering for Seamless Integration and Performance

Recognizing that every industrial process has unique requirements, our 316 stainless steel water tank is entirely customized. From specific capacities and dimensions to unique connection types, instrumentation ports (for temperature, pressure, level, pH), and agitation systems, every aspect is tailored to your exact operational needs. This bespoke approach ensures seamless integration into your existing production lines, maximizing efficiency, optimizing space utilization, and providing a perfect fit that generic tanks cannot achieve. Its robust construction guarantees durability and reliability, offering a long-term, high-value asset for your critical liquid storage requirements.

معلمة المنتج

The Stark Water Customized Heating 316 Stainless Steel Water Tank is precision-engineered for critical applications requiring heating, sterility, and insulation. Here are its key technical specifications:

| المعلمة | المواصفات/خيارات التخصيص |

|---|---|

| التركيز على الكلمات المفتاحية الأساسية | 316 stainless steel water tank design and capabilities. |

| مواد البناء | Premium 316 Stainless Steel (typically 316L for low carbon). |

| الطاقة الاستيعابية | قابلة للتخصيص حسب متطلبات العميل (على سبيل المثال، من 100 لتر إلى 50,000 لتر أو أكثر). |

| طريقة التسخين | Customized Heating Jacket (Dimple, Coil, or Full), Internal Heating Coils, or Electric Heating Elements. Designed for steam, hot water/oil, or electricity. |

| العزل | Yes, insulated with high-performance materials (Polyurethane Foam, Mineral Wool) and outer stainless steel cladding for thermal efficiency. |

| نوع التصميم | Vertical or Horizontal, Cylindrical, with dished or conical heads (for complete drainage). |

| تشطيب السطح الداخلي | Mirror polished (e.g., Ra < 0.4 μm) for enhanced hygiene and cleanability; electro-polishing available. |

| تشطيب السطح الخارجي | لمسة نهائية مصقولة غير لامعة أو غير لامعة أو #2B على الكسوة الخارجية. |

| الحد الأقصى. ضغط التشغيل | Atmospheric to pressurized (e.g., 0-0.6 MPa / 0-6 Bar), designed to client’s pressure requirements. |

| نطاق درجة حرارة التشغيل | Customizable, designed to maintain specific temperatures (e.g., -10°C to 150°C). |

| التحريض (اختياري) | Top-mounted or side-mounted agitators with various impeller types for mixing sensitive liquids. |

| التوصيلات/التركيبات |

|

| Aseptic Features | Sanitary welding, crevice-free design, complete drainability, CIP/SIP compatibility, sterile connections. |

| الامتثال للمعايير | Designed and manufactured according to GMP standards, ASME BPE, CE, ISO (as required by client). |

الصناعة المطبقة

The Stark Water Customized Heating 316 Stainless Steel Water Tank is an indispensable and highly adaptable asset for industries where maintaining the highest levels of hygiene, precise temperature control, and sterility is paramount. Its robust 316 stainless steel construction and customizable features make it ideal for a wide range of critical applications:

- Pharmaceutical Industry: Critical for storing and heating Purified Water (PW), Water for Injection (WFI), and Highly Purified Water (HPW), as well as processing and storing sterile solutions, media, and active pharmaceutical ingredients (APIs) under controlled temperatures, strictly adhering to GMP guidelines.

- Biotechnology: Essential for storing and processing sterile buffers, cell culture media, and sensitive biological products that require precise temperature maintenance and aseptic conditions for optimal yield and integrity.

- Food & Beverage Industry (High-Purity/Sterile Lines): Used for hygienic storage and heating/cooling of purified process water, ingredient water (e.g., for infant formula, specialized beverages), milk, syrups, and other temperature-sensitive liquid food products, ensuring safety, taste, and extended shelf life.

- Cosmetics & Personal Care: Provides sterile and temperature-controlled storage for purified water, emulsions, and ingredients used in premium creams, lotions, shampoos, and other personal care products, preserving stability and preventing contamination.

- High-Purity Chemical Processing: For storing and heating/cooling specialized, high-purity chemicals where contamination must be avoided and precise temperature control is vital for reaction kinetics or product stability.

- Laboratories & Research Facilities: Custom tanks for storing temperature-sensitive reagents, culture media, or purified water in large volumes for research and development purposes, often requiring sterile conditions.

- Breweries & Wineries (Specialized): For specific processes requiring precise heating/cooling and hygienic storage of wort, beer, or wine at critical stages, contributing to product consistency and quality.

- Water Treatment Plants (Sterile Process Water): For storing heated, sterile process water used in sensitive downstream applications that demand aseptic conditions.

الميزة الأولى

الميزة الثانية

المنتجات ذات الصلة

منتجات ذات صلة

الأسئلة الشائعة

س1: ما المدة التي يستغرقها نظام التناضح العكسي؟

يعتمد عمر نظام التناضح العكسي على جودة المياه والصيانة. عادةً ما يدوم الغشاء من 2-3 سنوات، بينما يمكن أن يدوم النظام نفسه لأكثر من 10 سنوات مع العناية المناسبة.

س2: هل يمكن تخصيص النظام بناءً على ظروف المياه المختلفة؟

نعم، جميع أنظمتنا قابلة للتخصيص بالكامل. نقوم بتحليل تقرير المياه الخاص بك واحتياجات التطبيق قبل تقديم حلول مصممة خصيصًا.

س3: ما هي المعايير التي تتوافق معها معدات STARK؟

تتوافق منتجاتنا مع معايير CE وISO 9001، ويمكن تصميمها لتلبية لوائح إقليمية أو معايير صناعية محددة عند الطلب.

س4: ما هو وقت تسليم أنظمة STARK RO؟

يتم شحن الأنظمة القياسية في غضون 7-15 يومًا. بالنسبة للطلبات المخصصة، قد تمتد المهلة الزمنية إلى 20-25 يومًا حسب درجة التعقيد.

السؤال 5: هل تقدمون الدعم الفني أو إرشادات التثبيت؟

نعم. نحن نقدم وثائق فنية كاملة، وإرشادات عن بُعد عبر الفيديو، ويمكننا إرسال مهندسين دوليًا عند الطلب.

س6: ما الذي يتضمنه عرض أسعارك؟

يشمل عرض أسعارنا نظام التناضح العكسي الكامل، ولوحة التحكم، والمضخات، ووحدات المعالجة المسبقة، وجميع التجهيزات اللازمة. ويمكن تضمين أدوات التركيب وقطع الغيار عند الطلب.