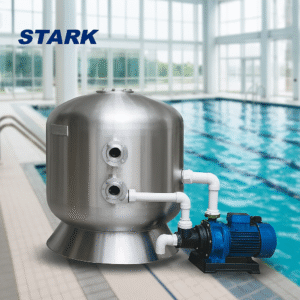

Stainless Steel Multimedia Mechanical Filter Use For Automatic Sand Filter, Carbon Quartz Filter In Water Treatment Plant

STARK’s stainless steel mechanical filter is engineered for automatic sand filtration and carbon-quartz media applications. With its durable SS304/316 construction and high-flow design, it ensures effective removal of suspended solids in industrial and municipal water treatment systems.

وصف المنتج

Robust Stainless Steel Mechanical Filter for Sand, Carbon, and Quartz Media

إن Stainless Steel Mechanical Filter from STARK is designed for heavy-duty multimedia filtration tasks in water treatment systems. Built with corrosion-resistant SS304 or SS316 materials, it houses automatic filtration media such as quartz sand, activated carbon, and anthracite to efficiently reduce turbidity, suspended solids, and organic matter.

This mechanical filter features an automatic backwash function, allowing for continuous operation with minimal manual intervention. The internal water distributor and collector ensure even flow distribution and stable pressure across the filtration bed, extending media life and maintaining consistent output quality.

Key Features:

- SS304/316 stainless steel shell for high corrosion resistance

- Supports various filter media: sand, carbon, quartz, anthracite

- Automatic backwashing system for uninterrupted operation

- Top-mounted manhole and pressure release valve

- Uniform inlet/outlet flow design to prevent channeling

- Customizable size and configuration based on treatment capacity

معلمة المنتج

| المعلمة | المواصفات |

|---|---|

| اسم المنتج | Stainless Steel Multimedia Mechanical Filter |

| المواد | SS304 / SS316 (optional) |

| Filter Media | Quartz sand, activated carbon, anthracite, gravel |

| Operation Mode | Automatic / Manual |

| Cleaning Method | Automatic backwashing |

| Design Pressure | 0.6 – 1.6 MPa |

| Applicable Flow Rate | 1 – 100 m³/h (customizable) |

| حجم المدخل/المخرج | DN50–DN300 (as per capacity) |

| Manhole | Top-mounted with clamp or flange |

| التطبيقات | Pre-filtration in water treatment plants |

الصناعة المطبقة

- Municipal water treatment – suspended solids and turbidity removal

- Industrial pre-filtration before RO/UF systems

- Desalination plant intake protection

- Cooling tower water conditioning

- Food & beverage process water treatment

- Textile, paper, and dyeing wastewater filtration

- Groundwater and surface water purification

الميزة الأولى

Automatic Backwash for Continuous, Unattended Operation

The stainless steel mechanical filter features a programmable backwashing system that enables efficient media cleaning without interrupting filtration. This ensures long service life, stable flow rates, and reduced operational labor.الميزة الثانية

High Corrosion Resistance and Customizable Design

Constructed from SS304 or optional SS316 stainless steel, this filter housing is built to withstand harsh chemical and marine environments. Its modular design allows customization in size, connection type, and media configuration to meet diverse project requirements.المنتجات ذات الصلة

منتجات ذات صلة

الأسئلة الشائعة

س1: ما المدة التي يستغرقها نظام التناضح العكسي؟

يعتمد عمر نظام التناضح العكسي على جودة المياه والصيانة. عادةً ما يدوم الغشاء من 2-3 سنوات، بينما يمكن أن يدوم النظام نفسه لأكثر من 10 سنوات مع العناية المناسبة.

س2: هل يمكن تخصيص النظام بناءً على ظروف المياه المختلفة؟

نعم، جميع أنظمتنا قابلة للتخصيص بالكامل. نقوم بتحليل تقرير المياه الخاص بك واحتياجات التطبيق قبل تقديم حلول مصممة خصيصًا.

س3: ما هي المعايير التي تتوافق معها معدات STARK؟

تتوافق منتجاتنا مع معايير CE وISO 9001، ويمكن تصميمها لتلبية لوائح إقليمية أو معايير صناعية محددة عند الطلب.

س4: ما هو وقت تسليم أنظمة STARK RO؟

يتم شحن الأنظمة القياسية في غضون 7-15 يومًا. بالنسبة للطلبات المخصصة، قد تمتد المهلة الزمنية إلى 20-25 يومًا حسب درجة التعقيد.

السؤال 5: هل تقدمون الدعم الفني أو إرشادات التثبيت؟

نعم. نحن نقدم وثائق فنية كاملة، وإرشادات عن بُعد عبر الفيديو، ويمكننا إرسال مهندسين دوليًا عند الطلب.

س6: ما الذي يتضمنه عرض أسعارك؟

يشمل عرض أسعارنا نظام التناضح العكسي الكامل، ولوحة التحكم، والمضخات، ووحدات المعالجة المسبقة، وجميع التجهيزات اللازمة. ويمكن تضمين أدوات التركيب وقطع الغيار عند الطلب.