STARK نظام تصفية التناضح العكسي الكبير STARK نظام تصفية التناضح العكسي محطة معالجة تنقية التحلية للبيع سعر الماكينة ro

Elevate your water supply with Stark Water’s Big Reverse Osmosis Filter System. هذه القوة reverse osmosis filter system is a comprehensive desalination and purification treatment plant, designed for large-scale industrial and municipal needs. Delivering exceptional water quality and efficiency, it’s a top-tier RO machine available at a competitive price.

وصف المنتج

For large-scale industrial operations, municipalities, and communities facing critical water scarcity or quality challenges, a robust and highly efficient purification solution is essential. The Stark Water Big Reverse Osmosis Filter System is engineered to meet these immense demands, providing a comprehensive and reliable answer for desalination, purification, and overall water treatment. This state-of-the-art reverse osmosis filter system is a strategic investment in securing a sustainable and high-quality water supply.

Large-Scale Desalination and Purification Capabilities

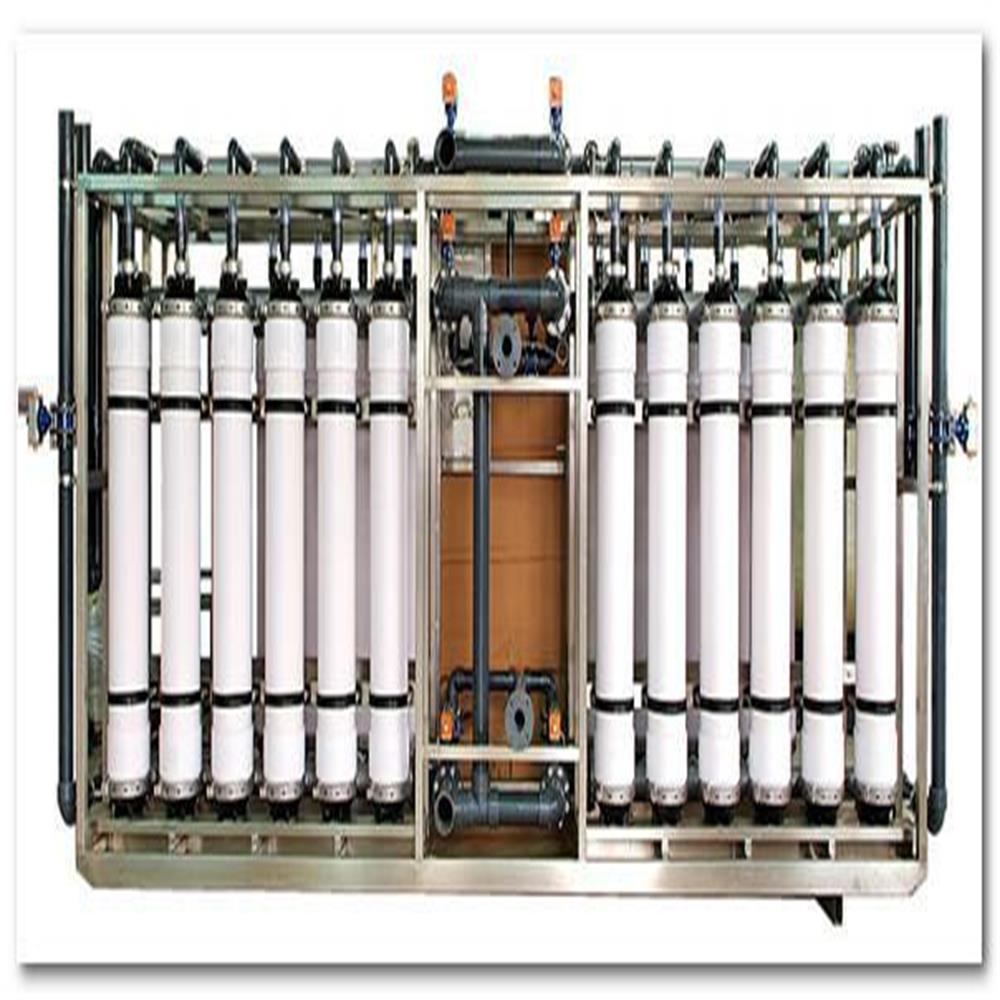

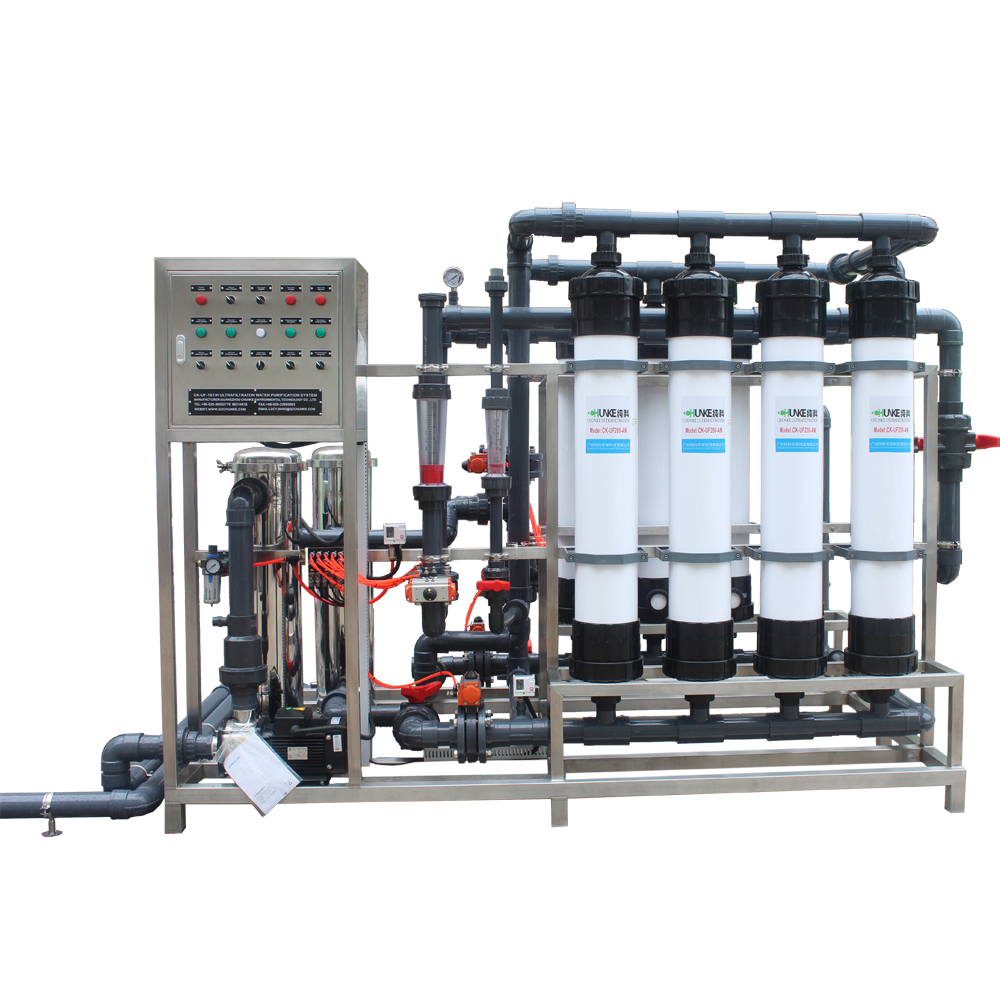

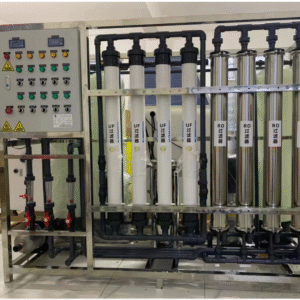

Our Big Reverse Osmosis Filter System is designed for substantial capacity, making it suitable for major industrial needs or serving large populations. It excels as a complete desalination purification treatment plant, capable of transforming highly saline water sources, including seawater and brackish groundwater, into fresh, potable water. Utilizing advanced thin-film composite (TFC) membranes and high-pressure pumping technology, it achieves exceptional contaminant rejection rates, effectively removing up to 99.7% of dissolved salts, minerals, heavy metals, organic compounds, bacteria, and viruses. This comprehensive purification ensures that the treated water consistently meets the most stringent international standards for drinking water or industrial process requirements.

A Complete RO Machine for Sale

This system is presented as a complete RO machine for sale, encompassing all necessary stages for effective purification. It typically includes:

- Advanced Pre-treatment: Multi-media filters (sand, activated carbon), water softeners (if needed), and micron cartridge filters to protect the delicate RO membranes from fouling and extend their lifespan.

- High-Pressure RO Module: Robust membrane pressure vessels housing high-rejection RO membranes, driven by energy-efficient, high-pressure pumps.

- Post-treatment (Optional but Recommended): Depending on desired final water quality, options like UV sterilization for microbiological control, chemical dosing for pH adjustment or disinfection, and advanced deionization (EDI) for ultra-pure water production can be integrated.

- Sophisticated Control System: Fully automated PLC control with Human Machine Interface (HMI) for real-time monitoring of critical parameters, automatic cleaning cycles (CIP), alarm functions, and remote access capabilities for optimal operational management.

The integrated design ensures seamless operation and maximum efficiency, simplifying management of complex large-scale water treatment processes.

Optimized Efficiency and Competitive Price

Investing in the Stark Water Big Reverse Osmosis Filter System is a commitment to long-term efficiency and value. We strive to offer a competitive price for this high-capacity **RO machine**, making advanced water treatment accessible for large-scale projects. The system’s high water recovery rates, coupled with energy-efficient components, translate into lower operational costs and reduced raw water consumption. Furthermore, the robust construction and automated operation minimize maintenance needs and downtime, ensuring a highly reliable and cost-effective solution for securing your purified water supply. It’s an investment that pays dividends through sustainable operations and consistent water quality.

معلمة المنتج

| المعلمة | المواصفات/خيارات التخصيص |

|---|---|

| التركيز على الكلمات المفتاحية الأساسية | Reverse osmosis filter system التصميم والأداء. |

| سعة المياه النقية | Customizable, typically ranging from 50 m³/hr to 500+ m³/hr (or higher for very large projects). Specified per client requirements. |

| توافق مصدر المياه الخام | متعددة الاستخدامات للغاية للمياه البلدية، ومياه الآبار، والمياه قليلة الملوحة (تصل المواد الصلبة الذائبة إلى 15,000 جزء في المليون)، أو مياه البحر (تصل المواد الصلبة الذائبة إلى 45,000 جزء في المليون لتكوين SWRO). |

| نوع غشاء التناضح العكسي | High-rejection, low-fouling Thin-Film Composite (TFC) RO Membranes (e.g., 8040 series, quantity scaled for capacity/TDS). Specialized SWRO membranes for desalination. |

| مضخة الضغط العالي | Heavy-duty, high-efficiency, corrosion-resistant centrifugal or positive displacement pumps, often with Variable Frequency Drives (VFDs) for optimized energy use. |

| نظام المعالجة المسبقة |

|

| معدل رفض الملح | ≥98.5% – 99.5% (BWRO); ≥99.5% – 99.7% (SWRO) |

| معدل استرداد المياه | 40% – 75% (BWRO); 30% – 50% (SWRO) – Dependent on raw water quality, desired recovery, and system design. |

| جودة المياه الناتجة | Meets WHO drinking water standards; customized for specific industrial process water needs (e.g., low TDS for boiler feed, ultra-pure water for electronics post-EDI). |

| مزود الطاقة | 3 أطوار، 380 فولت/415 فولت/460 فولت، 50 هرتز/60 هرتز (قابلة للتخصيص حسب المعايير الإقليمية). |

| نظام التحكم | Advanced Fully Automatic PLC Control with HMI (Human Machine Interface), real-time online monitoring of all critical parameters (TDS/conductivity, pressure, flow, temperature), auto-flush, CIP (Clean-in-Place), and comprehensive safety interlocks/alarms. Remote monitoring capability. |

| مواد البناء |

|

| متطلبات مياه المدخل |

|

| الأبعاد (تقريبي) | Large industrial footprint; fully customized based on capacity and configuration. |

| درجة حرارة التشغيل | 5 درجات مئوية - 45 درجة مئوية. |

| التصديق | مصممة لتلبية المعايير الدولية ذات الصلة (على سبيل المثال، ISO، CE، ASME، عند الطلب). |

الصناعة المطبقة

- مرافق المياه البلدية: Provides immense volumes of safe, potable drinking water for large cities, regions, or communities, especially vital in areas facing severe freshwater scarcity through large-scale desalination projects.

- Large Industrial Parks & Manufacturing Facilities: Supplies high-purity process water for diverse manufacturing operations, including electronics, automotive, textiles, and heavy industries, ensuring product consistency, preventing equipment damage, and meeting stringent quality standards.

- Major Food & Beverage Production Plants: Essential for producing vast quantities of purified water for beverage formulation (bottled water, soft drinks, breweries, dairies), food ingredient processing, and comprehensive cleaning-in-place (CIP) systems, guaranteeing product safety and quality.

- Power Generation & Energy Sector: Critical for boiler feed water purification in thermal and nuclear power plants, cooling tower make-up water, and turbine washing, preventing scaling, corrosion, and improving energy efficiency of high-pressure equipment.

- Pharmaceutical & Biotechnology Giants: Used as the foundational purification stage to generate Purified Water (PW) and pre-treat for Water for Injection (WFI) for drug manufacturing, large-scale bioreactors, and sterile environments, adhering to the strictest GMP standards.

- صناعة التعدين والمعادن: For large-volume process water, mineral extraction, and treatment of challenging water sources (e.g., acid mine drainage), contributing to operational efficiency and environmental compliance.

- صناعة النفط والغاز: Provides treated water for injection in oil recovery, fracking operations, and various process applications, often requiring large volumes and robust treatment.

- Chemical Water Treatment Plants (Core Component): Serves as the primary purification unit in comprehensive chemical water treatment plants, providing vast quantities of high-purity water for complex chemical formulations, dilutions, and reducing the chemical load on subsequent treatment steps.

- معالجة مياه الصرف الصحي وإعادة استخدامها (الأنظمة المتقدمة): Employed in advanced wastewater treatment facilities to produce high-quality effluent suitable for industrial reuse, agricultural irrigation, or even indirect potable reuse, promoting water conservation.

الميزة الأولى

الميزة الثانية

المنتجات ذات الصلة

منتجات ذات صلة

الأسئلة الشائعة

س1: ما المدة التي يستغرقها نظام التناضح العكسي؟

يعتمد عمر نظام التناضح العكسي على جودة المياه والصيانة. عادةً ما يدوم الغشاء من 2-3 سنوات، بينما يمكن أن يدوم النظام نفسه لأكثر من 10 سنوات مع العناية المناسبة.

س2: هل يمكن تخصيص النظام بناءً على ظروف المياه المختلفة؟

نعم، جميع أنظمتنا قابلة للتخصيص بالكامل. نقوم بتحليل تقرير المياه الخاص بك واحتياجات التطبيق قبل تقديم حلول مصممة خصيصًا.

س3: ما هي المعايير التي تتوافق معها معدات STARK؟

تتوافق منتجاتنا مع معايير CE وISO 9001، ويمكن تصميمها لتلبية لوائح إقليمية أو معايير صناعية محددة عند الطلب.

س4: ما هو وقت تسليم أنظمة STARK RO؟

يتم شحن الأنظمة القياسية في غضون 7-15 يومًا. بالنسبة للطلبات المخصصة، قد تمتد المهلة الزمنية إلى 20-25 يومًا حسب درجة التعقيد.

السؤال 5: هل تقدمون الدعم الفني أو إرشادات التثبيت؟

نعم. نحن نقدم وثائق فنية كاملة، وإرشادات عن بُعد عبر الفيديو، ويمكننا إرسال مهندسين دوليًا عند الطلب.

س6: ما الذي يتضمنه عرض أسعارك؟

يشمل عرض أسعارنا نظام التناضح العكسي الكامل، ولوحة التحكم، والمضخات، ووحدات المعالجة المسبقة، وجميع التجهيزات اللازمة. ويمكن تضمين أدوات التركيب وقطع الغيار عند الطلب.