This practical guide explains what ultrafiltration (UF) is, where ultrafiltration applications fit in modern trains, and how to select, size, operate and maintain UF systems. You’ll find quick sizing rules, O&M checklists, common pitfalls, and FAQs to help you execute projects faster and with confidence.Across industries, ultrafiltration applications reduce SDI and bioload while stabilizing downstream RO.

Reviewed by Stark Water Process Engineering Team · Last reviewed: 20 Oct 2025

1) Ultrafiltration applications: industrial & municipal use case

Ultrafiltration is a pressure-driven membrane process (typical MWCO ~1–100 kDa or 0.01–0.1 µm equivalent) that retains colloids, suspended solids, and microorganisms while allowing water and dissolved salts to pass. In most ultrafiltration applications, UF serves as:

- Pretreatment before RO/EDI to stabilize SDI/turbidity and protect high-pressure membranes.

- Clarification/polishing in food & beverage to reduce haze and microload while preserving flavor compounds.

- Tertiary filtration for municipal reuse prior to disinfection or advanced treatment.

UF vs MF/RO: UF removes colloids/microbes more than microfiltration at similar pressures, yet it does not desalinate like RO.

2) Industrial & municipal ultrafiltration applications

Drinking & rural water

- Consistent turbidity & SDI control; barrier to bacteria and protozoa.

- Automates small decentralized plants; reduces coagulant dependency.

Typical ultrafiltration applications include surface-water clarification before RO.

Food & beverage

- Juices & beverages: clarification + micro reduction while preserving aromas; cold processing avoids thermal damage.

- Tea beverages: clarity and shelf-life improvement without heavy fining agents.

- Dairy: protein concentration/fractionation (with RO/NF when needed); improved yield vs. thermal steps.

- Brewing & wine: haze removal; DE-free alternatives; stable sensory profile.

- Oils/fats: membrane degumming & clarification to reduce clay/bleaching earth usage.

Pharma & bioprocess

- Pyrogen/endotoxin reduction as part of validated systems; sanitary hardware and documented CIP/SIP are required.

Validated ultrafiltration applications help control endotoxin and bioburden.

Botanical/TCM extracts

- Solvent-free clarification; fractionates high-MW actives from fines for better downstream concentration.

Heavy industry & RO pretreatment

- Power, steel, and chemical plants: UF ahead of RO for boiler make-up and recycle streams.

- Seawater RO pretreatment to stabilize SDI and reduce cartridge consumption.

For RO make-up, ultrafiltration applications stabilize SDI and cut cartridge usage.

Municipal reuse & MBR

- Tertiary filtration prior to disinfection or AOP; complements MBR systems for low-turbidity reuse.

3) Selection checklist (choose the right UF design)

- Feed quality: turbidity/SDI, oils/grease, bioload; temperature and viscosity effects.

- Performance targets: microbial barrier, clarity/haze, SDI to protect RO, or product quality in F&B.

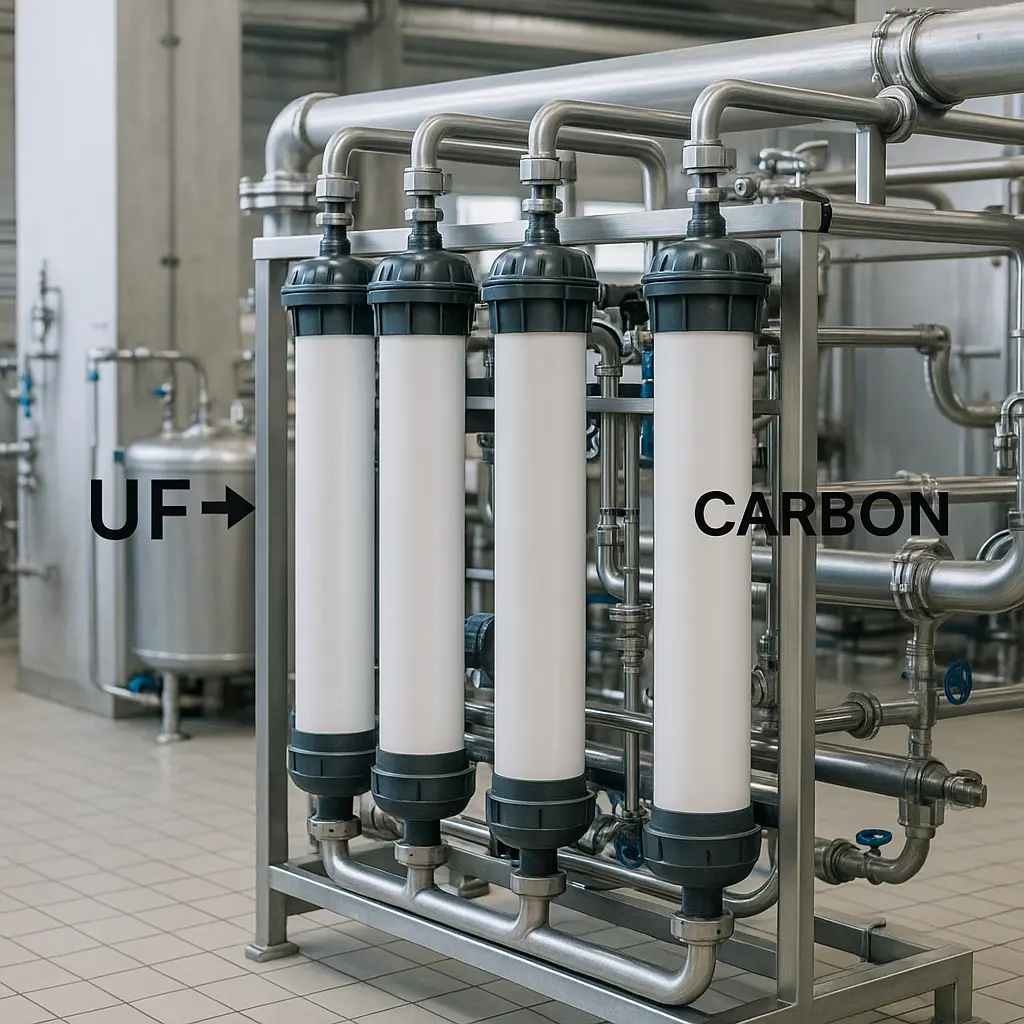

- Module format: pressurized vs. submerged; inside-out vs. outside-in hollow fiber; spiral-wound UF for specific skids.

- Materials & hygiene: PVDF/PES/PS; potting chemistry; 316L piping, hygienic clamps and drains for sanitary service.

- Hydraulics: design flux windows, crossflow/scour velocity, allowable TMP, and cleaning windows.

- Integration: strainers ahead of feed pumps; optional carbon/softening; downstream RO/EDI tie-ins.

- الامتثال: FDA/EC food contact (where applicable), 3-A, and site validation expectations.

4) Quick sizing worksheet

Use the following starting points and confirm with vendor datasheets and pilots.

| Scenario | Typical clean flux* | Design TMP (clean → max) | Backwash/air-scour | الملاحظات |

|---|---|---|---|---|

| Drinking water pretreatment | 45–70 LMH | 0.1 → 0.8 bar | 30–60 min, 30–90 s | Automate integrity tests; maintain SDI <3 for RO. |

| F&B clarification (cold) | 20–50 LMH | 0.2 → 1.0 bar | 15–30 min, CEB weekly | Hygienic drains; temperature effects on viscosity. |

| Industrial reuse (challenging feed) | 25–45 LMH | 0.2 → 1.2 bar | 15–30 min, frequent CEB | Oil/grease control required; evaluate coagulant aid. |

*LMH = L/m²·h. Always confirm allowable flux/TMP for your specific membrane, temperature and chemistry.

Recommended pre-strainers

| Feed condition | Suggested strainer | Comment |

|---|---|---|

| General surface water | 100–200 µm basket/automatic screen | Protects pumps & fibers from large debris. |

| High solids or algae season | 50–100 µm with bypass flush | Increase backwash cadence and waste handling. |

| F&B hygienic service | Hygienic inline strainer (≤100 µm) | 316L body, sanitary connections and drains. |

5) Operations & maintenance

- Startup normalization: log clean water baseline for flux, ΔP, temperature and SDI.

- Routine: automated backwash/air-scour; chemically enhanced backwash (CEB) on ΔP/flux drift.

- CIP: alkaline for organics/biofilm, acidic for minerals; verify membrane compatibility with oxidants.

- Preservation: disinfection/biostatic storage when idle; keep housings full and air-free.

- Integrity tests: pressure-hold or marker tests at defined intervals; document results.

6) Common pitfalls & fast fixes

- Undersized strainers: upgrade mesh/area; check pump NPSH and cavitation noise.

- Insufficient scour/backwash: re-tune flows, durations and sequences; add air-scour if supported.

- Oxidant damage: confirm membrane’s free-chlorine limit; add dechlorination if needed.

- Temperature swings: correct flux to 20 °C equivalent; insulate/heat-trace hygienic lines.

- RO performance drop after UF: verify SDI, run integrity test, check carbon fines and biogrowth.

7) Mini case snapshots

- Tea beverage: UF clarified concentrate at 30 LMH, ΔP<0.6 bar; reduced fining agent use by ~80%.

- Battery plant RO make-up: UF pretreatment cut cartridge spend by 65% and stabilized SDI at 2.2.

8) FAQs

What does UF remove compared with MF or RO?

UF removes colloids, bacteria and high-MW organics; MF targets larger particles; RO removes dissolved salts and organics (desalination).

Can UF replace coagulants in beverages?

Often UF reduces or eliminates fining/coagulants, but pilot testing is recommended to confirm clarity and flavor goals.

How often should I backwash or CIP?

Backwash every 15–60 minutes depending on feed; add weekly CEBs and periodic full CIP based on ΔP/flux trends.

Which materials are food-grade?

PVDF/PES membranes with approved potting, 316L stainless pipework, and sanitary elastomers—verify current food-contact declarations.

9) Next steps (RFQ & internal links)

Share your feed analysis and demand curve—we’ll size modules, hydraulics and cleaning strategy, and propose a hygienic package.

- طلب عرض أسعار

- Inside-out UF membrane guide

- Water treatment calculators

- Stainless-steel tanks & housings

- Water treatment systems