This article is a wastewater plant upgrade roadmap for 2025, mapping diagnostics → BNR → phosphorus control → micropollutants → automation → reuse.

TL;DR — This engineer-ready roadmap turns policy pressure, new contaminants, and energy costs into a practical program. You will: (1) baseline gaps to 2025+ limits; (2) pick the right BNR path (A2/O, step-feed, IFAS/MBBR, MBR, or shortcut N/Anammox); (3) secure phosphorus with EBPR + chem-P + tertiary filtration; (4) add targeted advanced treatment for micropollutants (ozone/UV-AOP + BAC, or RO/NF for reuse); (5) cut OPEX via diffuser/blower upgrades, DO/ABAC control, and smart dosing; (6) modernize instrumentation, SCADA, and cybersecurity; (7) phase construction safely with KPI-driven commissioning.

Back to: Municipal & Public Infrastructure Water Treatment Solutions

1) Why 2025 Matters for Your Wastewater Plant Upgrade Roadmap

Policy & limits are tightening on TN/TP and moving tertiary polishing to mainstream. Micropollutants (PFAS, pharmaceuticals, endocrine disruptors) are entering permits and reuse criteria. Meanwhile, aeration still drives 40–60% of plant energy; chemicals are volatile; climate extremes demand resilience and wet-weather tactics; and OT cybersecurity is no longer optional.

2) Baseline Diagnostics & Readiness

2.1 What to measure (4–8 weeks)

- Influent/Effluent: BOD/COD, TSS, NH4-N, NO3-N, TN, PO4-P, TP, pH, alkalinity; optional UV254/TOC for organics.

- Process: MLSS/MLVSS, SVI, DO profiles (per zone), ORP, temperature, SRT, RAS/WAS rates, internal recycle.

- Energy & Chemicals: blower/pump kWh; chemicals per m³ (coagulant, polymer, external carbon, alkali).

- Micropollutants (screening) if reuse or potable-reuse is in scope.

2.3 Readiness scorecard

| Domain | Today | 2025+ Target | Gap |

|---|---|---|---|

| Nitrogen | TN < 15 mg/L (seasonal) | TN ≤ 10 mg/L (year-round) | BNR + control |

| Phosphorus | TP ~1.5 mg/L | TP ≤ 0.5 mg/L | EBPR/chem-P + tertiary |

| Micropollutants | N/A | Ozone/UV-AOP + BAC | Add advanced treatment |

| Energy | 0.45 kWh/m³ | ≤ 0.32 kWh/m³ | Blower/diffuser/DO control |

2.2 Asset & capacity checks

- Hydraulic peaking, EQ/bypass risks, primary clarifier performance.

- Aeration grids, blowers, mixers; condition of diffusers and headers.

- Tertiary units (cloth/disk/sand filters) and disinfection.

- Electrical/OT: MCCs, drives, PLCs, historian/SCADA, network zoning.

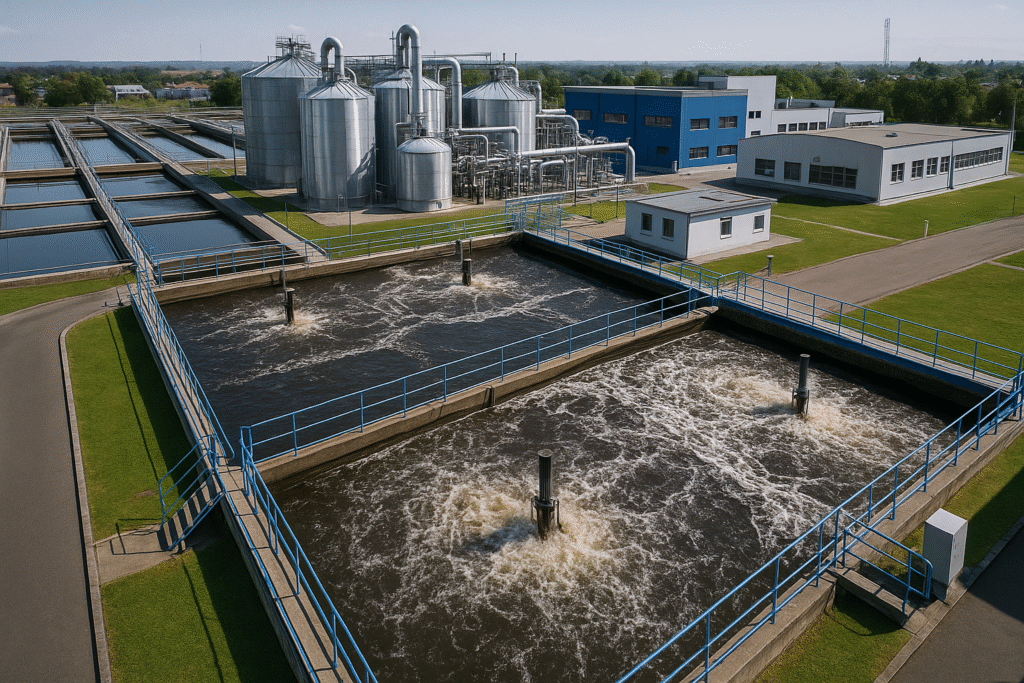

3) The BNR Core: Choose Your Nitrogen Path

3.1 CAS with BNR (A2/O, MLE, Step-feed)

Best when you have basin volume and working secondary clarifiers. Key settings: aerobic DO 1.5–2.0 mg/L; anoxic DO < 0.2 mg/L; internal recycle 2–4×; SRT > 8–12 d (winter). Capture internal carbon (primary fermentation) before adding methanol/acetate.within the wastewater plant upgrade roadmap, MBR is the most reuse-ready path

3.2 IFAS/MBBR

Media in selected zones boosts nitrifier retention and winter stability with modest civil works. Requires media screens, mixers, and oxygen transfer recalibration.within the wastewater plant upgrade roadmap, MBR is the most reuse-ready path

3.3 MBR (Membrane Bioreactor)

High MLSS and absolute solids separation deliver low turbidity, compact footprint, and reuse-ready effluent. Typical flux 15–30 LMH; TMP < 0.3 bar; disciplined pre-screening and air scouring. Ideal if clarifiers are a bottleneck or reuse is likely.

3.4 Shortcut N & Sidestream (PNDN/Anammox)

Where NH4 loads are high, shortcut nitrogen or sidestream Anammox cuts oxygen and external carbon demand. Start sidestream (centrate/filtrate) before mainstream.

Product path: evaluate MBR, aeration basins, and BNR modules for footprint-limited sites; add mixers, DO/NH4 probes, and blowers as packages.

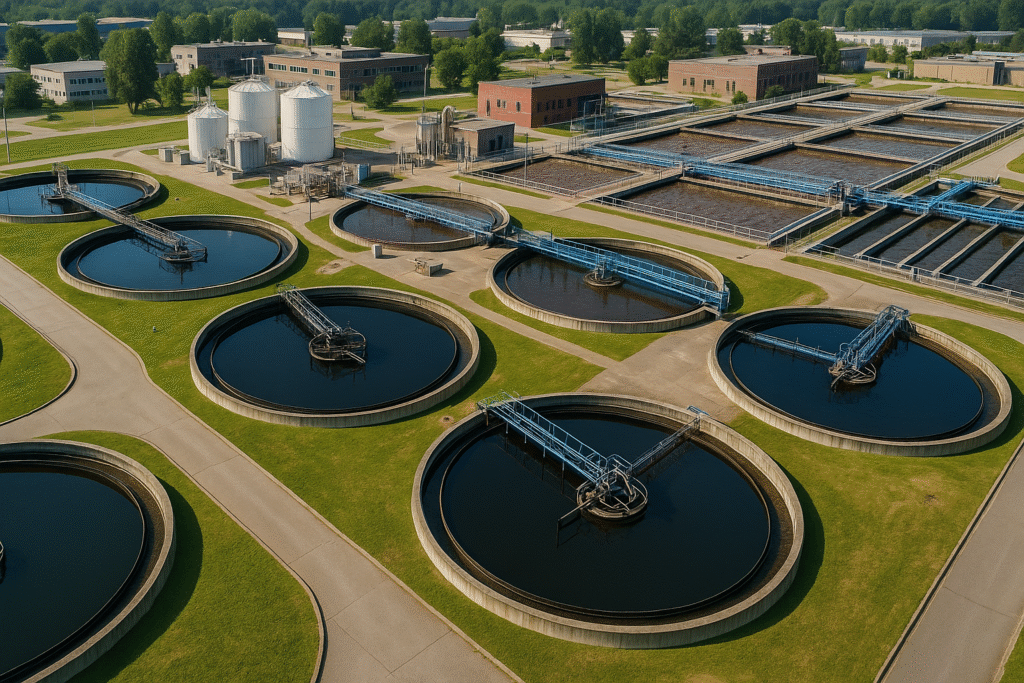

4) Phosphorus Control: EBPR, Chem-P & Tertiary

4.1 EBPR prerequisites

- True anaerobic selector with sufficient VFA; prevent nitrate bleed.

- SRT & temperature management to favor PAOs over GAOs.

4.2 Chemical phosphorus (trim or primary/tertiary)

Alum/ferric optimized by online orthophosphate and jar tests. Mind alkalinity and sludge production.

4.3 Tertiary filtration

Cloth/disk/sand filters stabilize sub-0.5 mg/L TP and polish TSS before AOP/ozone.

5) Micropollutants Strategy

- Ozonation (dose set by UV254/CT) oxidizes many pharmaceuticals and EDCs.

- UV-AOP (UV/H2O2) handles recalcitrants; quench H2O2 upstream of BAC.

- BAC (biologically active carbon) mineralizes by-products and stabilizes removal.

- RO/NF for stringent reuse; manage concentrate via sidestream treatment or blending per local rules.

Start with an ozone + BAC pilot; escalate to UV-AOP و ريال عماني if potable reuse is in scope.

6) Aeration & Energy Optimization

- Replace aged diffusers; verify α/β factors and SOTE in process conditions.

- Right-size blowers (turbo/screw) with VFDs; modern control maps avoid surge.

- Close the loop: DO 1.5–2.0 mg/L in aerobic zones; intermittent aeration for selectors; adopt ABAC (ammonia-based aeration control).

Energy KPIs: kWh/m³; kWh/kg BOD removed; blower share of plant kWh; aeration air per kg NH4-N oxidized.

7) Smart Dosing Systems

Tie dosing to real-time analytics, not fixed pacing:

- Coagulants/flocculants → feed-forward from turbidity/UV254; feedback from effluent PO4.

- External carbon → pace to NO3-N load and online NO3/ORP; consider carbon footprint.

- pH/alkalinity → protect nitrification and AOP performance.

Standardize with metering pumps, dosing skids, and analyzers for safety and documentation.

8) Sludge Line, Sidestream & Energy Recovery

- Thickening/dewatering: optimize polymers; track capture rate.

- Digestion: meso/thermo with thermal hydrolysis for more gas and Class A pathways.

- Sidestream: shortcut N/Anammox on centrate/filtrate to lighten mainstream loads.

- Energy: CHP or upgrading; heat integration with digesters and buildings.

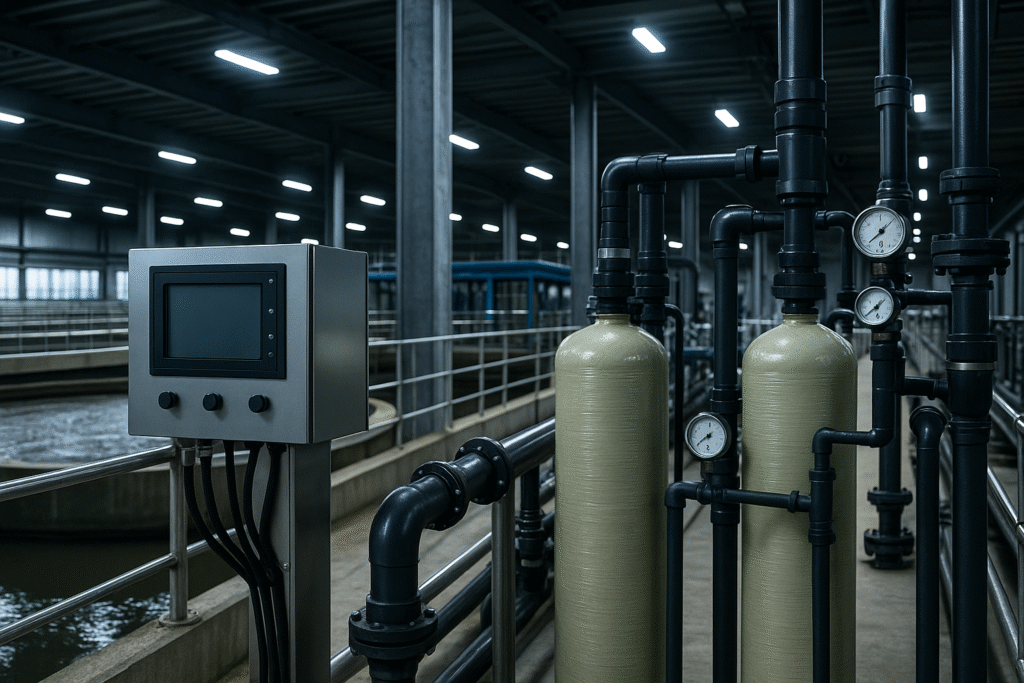

9) Instrumentation, SCADA, AI & Cybersecurity

9.1 Core online instruments

NH4/NO3, PO4, DO, ORP, MLSS, UV254/TOC; maintain and calibrate as a discipline.

9.2 SCADA & edge analytics

- Segment OT networks; role-based access; change logs and backups.

- Model-based setpoint optimization for blowers, RAS/WAS, dosing.

- Dashboards: “Operations today,” “Energy,” “Compliance risk,” “Maintenance next 7 days.”

9.3 AI for predictive operations

Use history + weather + influent forecasts to predict load, optimize air/carbon, and avoid violations. Start with operator-in-the-loop recommendations; move to closed-loop only after MoC and safety reviews.

10) Water Reuse Readiness (IPR/DPR)

- Design effluent turbidity/TOC compatible with ozone/BAC or RO trains.

- Reserve pad space and bypasses for future AOP/RO racks and BAC filters.

- Install monitoring stations and sampling points up-front.the wastewater plant upgrade roadmap prioritizes low-CAPEX control changes before concrete

Explore our plant modules for reuse-ready builds and sensors/dosing for monitoring.

11) CAPEX/OPEX & Phasing

11.1 Lifecycle view

- CAPEX bands: controls/diffusers (low), selectors/IFAS (medium), MBR/ozone/RO (high).

- OPEX drivers: aeration, chemicals, solids handling, maintenance, analytics.

- LCCA: model 20-year scenarios with energy price sensitivity and carbon cost where applicable.

11.2 Brownfield build-while-running

Maintain one train online while retrofitting another. Use temporary aeration and packaged dosing to bridge cutovers; enforce Management of Change, alarm thresholds, and hold points.

12) Permitting, Compliance & Risk

- Align early with your regulator on nutrient and reuse frameworks.

- HAZOP for chemical handling, confined spaces, UV/AOP safety, ozone off-gas.

- OT security risk assessments; backup/restore drills.

Disclaimer: Guidance is general. Validate with site data, pilots, and local codes.

13) 12-Month Wastewater Plant Upgrade Roadmap Playbook

- Months 1–2 — sampling/energy audit; ASM/CFD modelling; options.

- Months 3–4 — pilots (IFAS/MBR; ozone/BAC); DO/ABAC trials; SCADA scope.

- Months 5–6 — P&IDs, IO lists, cyber zoning, HAZOP, constructability.

- Months 7–10 — phased construction; FAT/SAT for blowers, skids, membranes, ozone, analyzers.

- Months 11–12 — commissioning: SRT ramp, DO trim, dose tuning, KPI validation, operator training.

14) KPIs & Dashboards

| KPI | Why it matters | الهدف النموذجي |

|---|---|---|

| Effluent NH4, NO3, TN | Compliance; air/carbon control | Per permit; seasonal guard bands |

| TP | EBPR/chem-P performance | ≤ 0.5 mg/L (lower with tertiary) |

| Turbidity/TSS | Solids capture; AOP readiness | < 2–5 NTU typical |

| Energy per m³ | OPEX | ≤ 0.30–0.35 kWh/m³ (site-specific) |

| Chemicals per m³ | Cost & footprint | Trending down with control |

| Membrane flux/DP | MBR health | Within vendor envelope; stable TMP |

| UV254/TOC reduction | Ozone/BAC/AOP performance | Per pilot curve & targets |

| Alarm response time | Operational resilience | < 5 min (critical) |

15) Snapshot Case Studies (Anonymized)

Case A — Step-feed + ABAC: TN 18→9 mg/L; energy −22%

50,000 m³/d CAS; winter nitrification weak. Actions: step-feed; internal recycle 3×; staged DO 0.5→1.8 mg/L; ammonia-based aeration control. Outcome: TN 9–11 mg/L year-round; blower kWh −22%.

Case B — EBPR + chem-P + tertiary: TP ≤ 0.3 mg/L

80,000 m³/d; TP limit 0.5 mg/L. Actions: anaerobic selector retrofit; ferric trim at filter influent. Outcome: 0.25–0.35 mg/L TP with manageable sludge increase.

Case C — MBR + Ozone/BAC: reuse-ready effluent

30,000 m³/d; land-constrained; future DPR. Outcome: turbidity < 0.2 NTU; UV254 −40–60%; ready to add UV-AOP/RO.

16) Next Steps & Contact

Map your baseline to this roadmap, shortlist the BNR path, and line up a pilot (IFAS/MBR or Ozone/BAC). We can package blowers, diffusers, dosing skids, sensors, and control to accelerate commissioning.

Author: STARK Process Engineering Team | Technical review: Senior Municipal Water Specialist | Last reviewed: 2025-08-14

References: WHO Guidelines for Drinking-water Quality; US EPA nutrient control/energy efficiency resources; EU Urban Waste Water Treatment Directive updates; IWA/WEF technical reports on EBPR, aeration, and ozone/BAC practice.