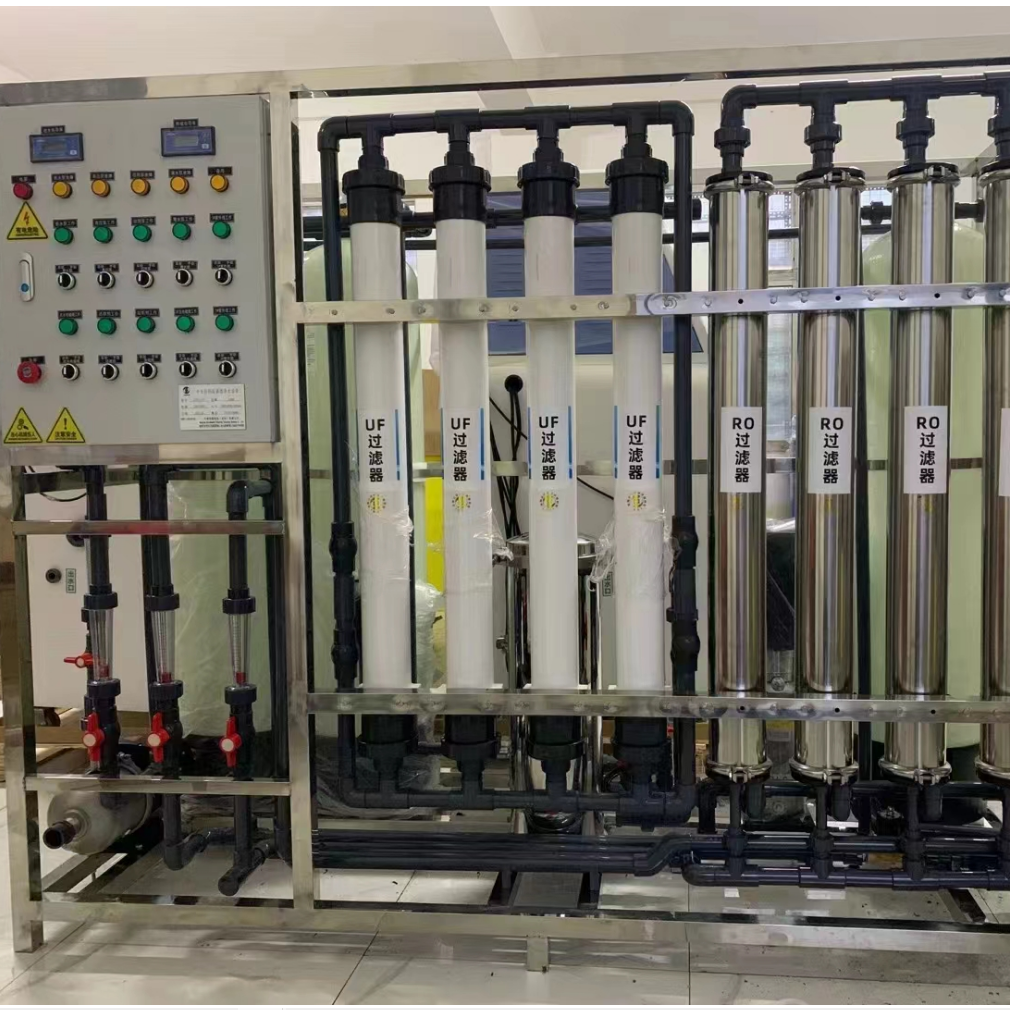

Reverse Osmosis ystem Water UF Equipment Manufacturer

Source high-quality Ultrafiltration systems directly from Stark Water, a leading UF equipment manufacturer. We specialize in advanced UF equipment and its integration with Reverse Osmosis systems for comprehensive water purification, offering tailored solutions for diverse industrial and commercial needs.

Product Description

In the global landscape of water purification, the demand for high-quality Ultrafiltration (UF) technology is continuously growing, driven by stringent water quality standards and the need for efficient pre-treatment solutions. Stark Water stands as a prominent UF equipment manufacturer, dedicated to designing, producing, and supplying advanced Ultrafiltration systems that deliver exceptional clarity and contaminant removal. Our commitment to direct manufacturing ensures that every piece of UF equipment meets the highest standards of performance, reliability, and long-term value.

As a Leading UF Equipment Manufacturer: Quality and Expertise

Our identity as a specialized UF equipment manufacturer means we control the entire production process, from concept and design to fabrication and rigorous testing. This comprehensive approach offers distinct advantages to our clients:

- Guaranteed Quality: Strict quality control procedures at every stage ensure that each UF system is built to exacting standards, providing consistent performance and durability.

- Direct from Source: Clients benefit from direct sourcing, which often translates to competitive pricing and transparent communication regarding product specifications and capabilities.

- Expertise and Innovation: Our dedicated R&D and engineering teams continuously work on enhancing UF technology, incorporating the latest advancements in membrane science and system design to offer cutting-edge solutions.

- Customization (OEM/ODM): As a manufacturer, we offer extensive OEM and ODM capabilities, allowing for the customization of UF systems to meet specific client requirements, branding needs, or unique project parameters.

We supply a wide range of UF equipment, from individual modules to complete skid-mounted systems, ready for seamless integration into diverse water purification applications.

Integrating Ultrafiltration with Reverse Osmosis System Water Purification

Ultrafiltration plays a pivotal role in optimizing overall water purification systems, particularly when integrated with a reverse osmosis system. While RO effectively removes dissolved solids, UF excels at physically removing suspended solids, turbidity, colloids, bacteria, and viruses. When used as a pre-treatment for RO, UF significantly enhances the performance and extends the lifespan of sensitive RO membranes by:

- Reducing Fouling: Preventing larger particles and microorganisms from accumulating on the RO membrane surface.

- Lowering SDI: Achieving a very low Silt Density Index (SDI), a critical parameter for RO feed water quality.

- Minimizing Chemical Use: Reducing the need for chemical pre-treatment often associated with conventional RO pre-filtration.

This synergy creates highly efficient water purification systems capable of treating a broad spectrum of raw water sources, delivering exceptional water quality for even the most demanding industrial, municipal, and commercial needs. Our expertise as a UF equipment manufacturer allows us to design and provide integrated solutions for superior water treatment.

Product Parameter

As a leading UF equipment manufacturer, Stark Water designs and produces Ultrafiltration systems with versatile and high-performance specifications. Here are typical and customizable technical parameters:

| Parameter | Specification / Customization Options |

|---|---|

| Core Keyword Focus | uf equipment manufacturer capabilities and product specifications. |

| System Capacity | Customizable, ranging from 1 m³/hr to 1000+ m³/hr (or GPM equivalent). Specified as per client requirements. |

| Filtration Technology | Ultrafiltration (UF) Membrane Filtration. |

| Membrane Type | Hollow Fiber UF Membrane (e.g., PVDF, PES, PAN), chosen based on feed water characteristics and application. |

| Pore Size | Typically 0.01 μm – 0.1 μm (e.g., 0.02 μm, 0.03 μm), selected for specific contaminant removal. |

| Operating Mode | Outside-in or Inside-out flow. Can be operated in dead-end or cross-flow filtration modes. Designed for optimal flux. |

| Operating Pressure | Typically 0.05 – 0.2 MPa (0.5 – 2 Bar / 7 – 29 PSI). Low pressure operation, customized for efficiency. |

| Raw Water Source Compatibility | Municipal Water, Well Water, Surface Water (rivers, lakes), Pre-treated Wastewater. Customizable based on detailed raw water analysis. |

| Output Water Quality | Turbidity Reduction: >99%; TSS Reduction: >99%; Bacteria/Virus Removal: >99.9999% (log 6 reduction or higher). SDI < 3. Achieves clarity suitable for RO feed. |

| Control System | Fully Automatic PLC Control with HMI. Customized for specific automation needs, including auto-backwash, chemical cleaning-in-place (CIP) sequences, alarm management, and remote monitoring/SCADA integration. |

| Power Supply | 3 Phase (380V/415V/460V, 50Hz/60Hz) or Single Phase (220V), customized as per regional standards. |

| Construction Material |

|

| Dimensions | Customized skid-mounted or modular design to fit client’s specific space requirements. |

| Operating Temperature | 5°C – 45°C (material dependent for broader range). |

| Certification | Designed and manufactured to meet relevant international standards (e.g., ISO, CE, upon request). OEM/ODM capabilities include meeting specific client standards. |

Applicable Industry

As a leading UF equipment manufacturer, Stark Water supplies its high-quality Ultrafiltration systems for a broad spectrum of industrial, municipal, and commercial sectors requiring advanced physical separation and robust pre-treatment. Our UF equipment is ideal for:

- Municipal Drinking Water Treatment: Provides primary purification or robust pre-treatment for urban waterworks, effectively removing turbidity, suspended solids, bacteria, and viruses from surface water sources to produce safe potable water.

- Reverse Osmosis System Water Pre-treatment: Essential for protecting sensitive RO membranes from fouling by suspended solids, colloids, and microorganisms, significantly extending RO membrane lifespan and reducing cleaning frequency.

- Wastewater Treatment & Reuse: Core component in advanced municipal and industrial wastewater treatment facilities (e.g., as part of Membrane Bioreactor (MBR) systems or tertiary treatment), producing high-quality effluent suitable for discharge, irrigation, or industrial reuse.

- Food & Beverage Industry: Used for clarification of process water, juices, wine, beer, and other beverages; and pre-treatment prior to sterile processes, ensuring product clarity and safety.

- Pharmaceuticals & Biotechnology: Provides purified water for process use and pre-filtration for sterile applications, ensuring high purity and compliance.

- Industrial Process Water: Supplies clean process water for various manufacturing operations, preventing fouling of equipment and improving product consistency.

- Cooling Tower & Boiler Feed Water: Removes suspended solids and microbial load from make-up water, preventing scaling, biofouling, and improving efficiency of large utility systems.

- Mining Operations: For treating process water and wastewater containing high levels of suspended solids and colloids.

- Electronics Manufacturing (Pre-UPW): Employed in pre-treatment stages for ultra-pure water (UPW) systems, ensuring removal of particulates to protect downstream purification for sensitive electronics manufacturing.

- OEM/ODM Partnerships: We manufacture UF equipment for other system integrators, distributors, and equipment suppliers under their brand, providing custom-designed solutions for their markets.

Advantage One

Stark Water, as a dedicated UF equipment manufacturer, offers the significant advantage of direct-from-manufacturer quality and extensive customization capabilities. We control the entire production process from R&D to fabrication and testing, ensuring every Ultrafiltration system is built to the highest standards of performance and durability. This direct approach translates into guaranteed product authenticity, reliable support, and competitive pricing due to reduced intermediaries. Furthermore, our OEM/ODM capabilities allow us to custom-engineer UF equipment precisely to your unique specifications—including capacity, dimensions, raw water characteristics, and integration needs—providing a tailored solution that optimizes efficiency and perfectly fits your project requirements, ensuring seamless integration with your reverse osmosis system or standalone purification plant.

Advantage TWO

Our Ultrafiltration equipment delivers superior filtration performance and optimized integration with Reverse Osmosis system water purification, enhancing overall water treatment efficiency. UF membranes provide a robust physical barrier, effectively removing suspended solids, turbidity, colloids, bacteria, and viruses, achieving exceptional water clarity. When utilized as a pre-treatment for RO, our UF equipment significantly extends the lifespan of sensitive RO membranes by preventing fouling, reducing chemical usage, and improving RO feed water quality. This synergy ensures more reliable and cost-effective operation for your entire water purification system, minimizing maintenance, reducing downtime, and consistently producing high-quality pure water for various demanding industrial, municipal, and commercial applications, thereby maximizing your return on investment.

Related Products

Ähnliche Produkte

FAQ

Q1: How long does the reverse osmosis system last?

The lifespan of a reverse osmosis system depends on water quality and maintenance. Typically, the membrane lasts 2–3 years, while the system itself can last over 10 years with proper care.

Q2: Can the system be customized based on different water conditions?

Yes, all our systems are fully customizable. We analyze your water report and application needs before providing tailored solutions.

Q3: What standards does STARK equipment comply with?

Our products comply with CE, ISO 9001, and can be designed to meet specific regional regulations or industry standards upon request.

Q4: What is the delivery time for STARK RO systems?

Standard systems are shipped within 7–15 days. For customized orders, lead time may extend to 20–25 days depending on complexity.

Q5: Do you provide technical support or installation guidance?

Yes. We provide full technical documentation, remote guidance via video, and can dispatch engineers internationally upon request.

Q6: What is included in your quotation?

Our quotation includes the full RO system, control panel, pumps, pre-treatment units, and all necessary fittings. Installation tools and spare parts can be included upon request.