160 m³/h UF Water Purifier | Hollow Fiber Ultrafiltration | STARK

160 m³/h UF Water Purifier | Hollow Fiber Ultrafiltration | STARK160 m³/h UF Water Purifier | Hollow Fiber Ultrafiltration | STARK

Descripción del producto

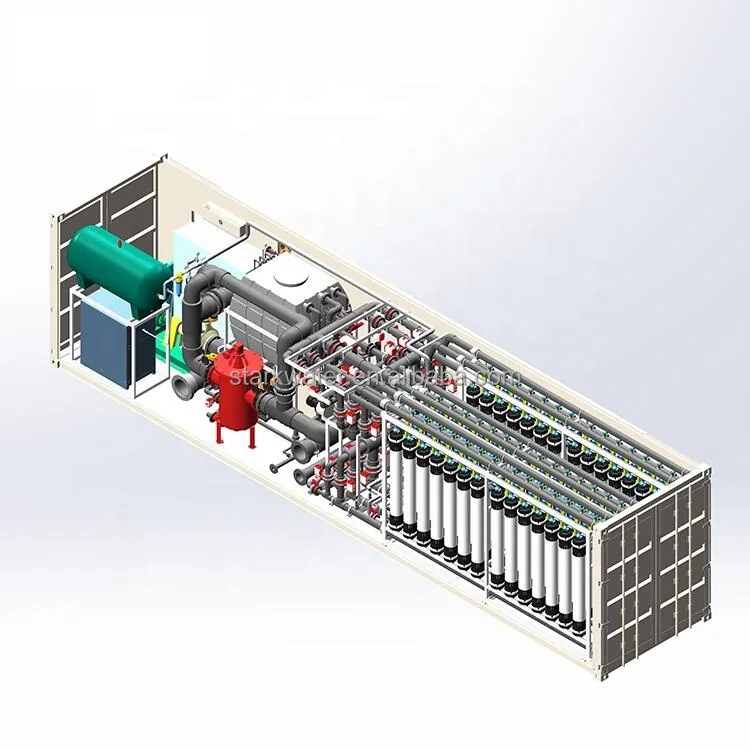

Each rack integrates backwash pumps, air scour and automated chemically enhanced backwash (CEB); periodic CIP (e.g., NaOCl/citric) restores permeability. The PLC sequences transmembrane pressure (TMP) limits, flux, backwash intervals and chemical dosing. Options include inline coagulation for difficult feeds, integrity testing, and UF→RO interlocks.

- Consistent filtrate SDI < 3 for RO pretreatment (when designed with inline coagulation/flux setpoints)

- Modular racks allow future capacity expansion beyond 160 m³/h

- Food-grade or industrial build; SS/UPVC wetted piping per duty

Note: Final design is engineered from feed turbidity/SDI, temperature and fouling indices. Pilot or jar-test data can be used to set flux, recovery and chemical regime.

Parámetros del producto

Technical Parameters

| Rated Capacity | 160 m³/h (continuous, configurable) |

|---|---|

| Membrane Type | Hollow fiber UF, PVDF or PES/PS, hydrophilic |

| Pore Size (nominal) | ~0.01–0.03 μm |

| Operation Mode | Dead-end with periodic backwash & air scour; CEB/CIP programmable |

| Typical Flux | 60–120 L/m²·h (temperature & feed dependent) |

| TMP Range | 0.05–0.25 MPa typical; max per module spec |

| Recuperación | ~90–95% (accounting for backwash/CEB losses) |

| Feed Water Limits | Turbidity ≤ 50 NTU typical (higher with coagulation); SDI < 8 recommended |

| Backwash | Every 20–60 min; filtrate/air; 30–60 s cycles |

| Chemicals | CEB/CIP: NaOCl, citric, NaOH (ranges per membrane OEM); pH 2–12 service |

| Filtrate Quality | Low turbidity; bacteria removal to log levels typical of UF membranes |

| Controls | PLC/HMI with TMP/flux control, integrity/pressure interlocks, data logging |

| Materials | Skid SS304; process piping SS/UPVC/CPVC; instruments SS/PTFE seals |

| Electrical | 380–415 V/50 Hz or 460 V/60 Hz; VFD pumps |

| Footprint | Modular racks; layout per site & access aisles |

| Notas | Values are typical; final BOM & guarantees confirmed after feed study. |

Industria aplicable

- Municipal water & groundwater plants — clarification & polishing

- Industrial RO pretreatment — stable SDI and biofouling control

- Bottled water & beverage — particulate removal and clarity

- Wastewater tertiary treatment & reuse — low-turbidity filtrate

- Desalination pretreatment — seawater/brackish UF before SWRO/ BWRO

- Surface water treatment — algae & pathogen barrier

Ventaja Uno

Advantage 1 — Stable Water Quality & RO-Ready

- UF barrier (~0.01–0.03 μm) for turbidity, colloids and most bacteria

- SDI control supports high RO uptime and longer membrane life

- Inline coagulation option for challenging surface waters

- Automatic integrity & pressure interlocks for safe operation

Ventaja DOS

Advantage 2 — Automated, Service-Friendly Operation

- PLC/HMI sequences backwash, air scour, CEB and CIP with recipes

- Modular racks, front access to pumps & valves for quick service

- VFD pumps optimize energy at variable flux and temperature

- Remote support & spare parts through STARK global network

Productos relacionados

Productos relacionados

PREGUNTAS FRECUENTES

P1: ¿Cuánto dura el sistema de ósmosis inversa?

La vida útil de un sistema de ósmosis inversa depende de la calidad del agua y del mantenimiento. Normalmente, la membrana dura entre 2 y 3 años, mientras que el sistema en sí puede durar más de 10 años con los cuidados adecuados.

P2: ¿Se puede personalizar el sistema en función de las diferentes condiciones del agua?

Sí, todos nuestros sistemas son totalmente personalizables. Analizamos su informe de aguas y sus necesidades de aplicación antes de ofrecerle soluciones a medida.

P3: ¿Qué normas cumplen los equipos STARK?

Nuestros productos cumplen las normas CE e ISO 9001, y pueden diseñarse para cumplir normativas regionales o estándares industriales específicos si así se solicita.

P4: ¿Cuál es el plazo de entrega de los sistemas de ósmosis inversa STARK?

Los sistemas estándar se envían en un plazo de 7-15 días. Para los pedidos personalizados, el plazo de entrega puede prolongarse hasta 20-25 días en función de la complejidad.

P5: ¿Ofrecen asistencia técnica u orientación para la instalación?

Sí. Proporcionamos documentación técnica completa, asistencia remota por vídeo y podemos enviar ingenieros al extranjero si así se solicita.

P6: ¿Qué incluye su presupuesto?

Nuestro presupuesto incluye el sistema de ósmosis inversa completo, el panel de control, las bombas, las unidades de pretratamiento y todos los accesorios necesarios. Si lo desea, podemos incluir herramientas de instalación y piezas de repuesto.