best cartridge filter

best cartridge filterbest cartridge filter

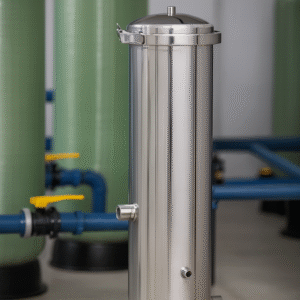

Achieve unparalleled filtration precision and purity with Stark Water’s best cartridge filter. Engineered for superior performance, this high-efficiency cartridge filter is designed to remove a wide range of particulates, ensuring optimal water quality and protecting downstream equipment across diverse industrial and commercial applications.

Descripción del producto

In countless industrial and commercial processes, achieving precise levels of fluid purity is paramount for product quality, equipment longevity, and operational efficiency. The selection of the right filter element is critical. Stark Water’s best cartridge filter is meticulously engineered to stand as the definitive choice for applications demanding superior filtration performance, reliability, and long-term value. We understand that “best” refers to a combination of exceptional efficiency, durability, and versatility.

Defining the Best Cartridge Filter: Precision, Capacity, and Reliability

Our commitment to providing the best cartridge filter is rooted in advanced design and manufacturing processes that ensure:

- High Efficiency Filtration: Available in both nominal and absolute micron ratings, our cartridge filters consistently capture particles down to extremely fine levels (e.g., from 0.5 micron to 100 micron), ensuring superior clarity and purity of the filtrate. This precision is vital for protecting sensitive downstream equipment.

- Exceptional Dirt-Holding Capacity: Engineered with advanced filter media and structural designs, our cartridges maximize dirt-holding capacity. This means longer service life between change-outs, reducing operational downtime, labor costs, and filter consumption.

- Broad Compatibility: Constructed from a variety of high-quality materials (e.g., polypropylene, pleated cellulose, wound polypropylene) and compatible with diverse fluid chemistries and temperatures, ensuring versatility across a wide range of industrial applications.

- Construcción robusta: Built to withstand high operating pressures and continuous flow, preventing premature filter failure due to pressure surges or media migration.

- Consistent Performance: Delivers stable and reliable filtration performance throughout its lifespan, ensuring consistent output quality without compromise.

These attributes collectively define a cartridge filter that not only meets but exceeds the most stringent filtration demands.

Versatile Applications and System Protection

Our best cartridge filter serves as a critical component in various stages of water and fluid purification systems. It is an indispensable pre-filter for more advanced purification technologies like Reverse Osmosis (RO) and Ultrafiltration (UF), effectively removing suspended solids and preventing membrane fouling. It also excels in post-filtration applications, polishing water after carbon filtration or ensuring the final clarity of process fluids. By providing a reliable barrier against particulates, our cartridge filters directly contribute to:

- Extending the lifespan of sensitive pumps, membranes, and other valuable equipment.

- Ensuring the purity and quality of final products in manufacturing.

- Reducing operational costs through fewer filter changes and less equipment maintenance.

- Meeting stringent regulatory and industry-specific purity standards.

Whether used for industrial process water, municipal drinking water final polishing, or specialized fluid clarification, our cartridge filters provide a cost-effective and high-performance solution.

Parámetros del producto

Stark Water’s best cartridge filter is engineered for high-performance filtration across various applications. Here are its key technical specifications:

| Parámetro | Especificaciones / Opciones de personalización |

|---|---|

| Palabras clave principales | best cartridge filter design and performance. |

| Filter Media Material | Polypropylene (PP) (melt-blown, string wound, pleated), Cellulose, Nylon, Polyester, Glass Fiber. Specified based on chemical compatibility and temperature. |

| Micron Rating | Available from 0.5 micron (absolute) to 100 micron (nominal or absolute). Common ratings: 1, 5, 10, 20 micron. |

| Filter Type | Melt Blown, String Wound, Pleated, Carbon Block (for taste/odor/chlorine), Resin Bonded. |

| Available Lengths | Standard lengths: 10″, 20″, 30″, 40″ (254mm, 508mm, 762mm, 1016mm). Custom lengths available. |

| Diámetro | Standard diameters: 2.5″ (slim), 4.5″ (Big Blue/Jumbo). Custom diameters available. |

| End Cap Configuration | DOE (Double Open End), SOE (Single Open End) with various fin/gasket types (e.g., 222, 226). |

| Max. Operating Pressure | Typically 0.4 MPa – 0.7 MPa (4 – 7 Bar / 58 – 100 PSI). Material and design dependent. |

| Max. Operating Temperature | Typically 40°C – 95°C (104°F – 203°F), dependent on filter material and end cap/gasket. |

| Flow Rate (per element) | Varies significantly based on length, diameter, micron rating, and media type. (e.g., 10 GPM for a 10″ 5 micron, up to 100+ GPM for larger pleated elements). |

| Dirt-Holding Capacity | High, designed for extended lifespan and reduced change-outs. Specified per filter type. |

| Conformidad | Food Grade (FDA CFR 21), NSF/ANSI standards compliance for materials (where applicable). |

Industria aplicable

Stark Water’s best cartridge filter is a highly versatile and essential component for achieving precise filtration and purity across a wide spectrum of industrial, commercial, and even advanced residential applications. Its broad compatibility and high performance make it ideal for:

- Reverse Osmosis (RO) Pre-filtration: Crucial for protecting sensitive RO membranes from fouling by suspended solids, sediment, and fine particulates, extending membrane lifespan and ensuring optimal RO performance.

- Food & Beverage Industry: Essential for clarifying process water, pre-filtration for bottling lines (beer, wine, juices, bottled water), and removal of fine particles from syrups, edible oils, and other liquid food ingredients to ensure product clarity, taste, and safety.

- Pharmaceutical & Biotechnology: Applied in various stages of process water filtration, pre-filtration for sterile filters, and removal of fine particulates from active pharmaceutical ingredients (APIs) and buffer solutions, ensuring high purity and compliance.

- Chemical Processing: Filters various chemicals, solvents, resins, and paints to remove fine solid impurities, ensuring product purity and protecting downstream equipment.

- Electronics & Semiconductor Manufacturing: Provides precise filtration for pre-treatment in ultra-pure water (UPW) systems, removing sub-micron particles to prevent defects in sensitive manufacturing processes.

- Oil & Gas Industry: Used for fine filtration of injection water, produced water, completion fluids, and various lubricants to protect pumps, injectors, and maintain fluid integrity.

- Power Generation: Filters boiler feed water, cooling tower make-up water, and condensate polishing systems, preventing scaling, corrosion, and improving overall plant efficiency.

- Laboratories & Research Facilities: Supplies purified water for analytical testing, glassware washing, and precise experimental procedures.

- Wastewater Treatment (Tertiary/Polishing): Used for final polishing of treated wastewater effluent to remove fine suspended solids before discharge or reuse.

- Cosmetics & Personal Care: For filtration of ingredients, purified water, and final products to ensure clarity, stability, and sterility.

Ventaja Uno

Ventaja DOS

Productos relacionados

Productos relacionados

PREGUNTAS FRECUENTES

P1: ¿Cuánto dura el sistema de ósmosis inversa?

La vida útil de un sistema de ósmosis inversa depende de la calidad del agua y del mantenimiento. Normalmente, la membrana dura entre 2 y 3 años, mientras que el sistema en sí puede durar más de 10 años con los cuidados adecuados.

P2: ¿Se puede personalizar el sistema en función de las diferentes condiciones del agua?

Sí, todos nuestros sistemas son totalmente personalizables. Analizamos su informe de aguas y sus necesidades de aplicación antes de ofrecerle soluciones a medida.

P3: ¿Qué normas cumplen los equipos STARK?

Nuestros productos cumplen las normas CE e ISO 9001, y pueden diseñarse para cumplir normativas regionales o estándares industriales específicos si así se solicita.

P4: ¿Cuál es el plazo de entrega de los sistemas de ósmosis inversa STARK?

Los sistemas estándar se envían en un plazo de 7-15 días. Para los pedidos personalizados, el plazo de entrega puede prolongarse hasta 20-25 días en función de la complejidad.

P5: ¿Ofrecen asistencia técnica u orientación para la instalación?

Sí. Proporcionamos documentación técnica completa, asistencia remota por vídeo y podemos enviar ingenieros al extranjero si así se solicita.

P6: ¿Qué incluye su presupuesto?

Nuestro presupuesto incluye el sistema de ósmosis inversa completo, el panel de control, las bombas, las unidades de pretratamiento y todos los accesorios necesarios. Si lo desea, podemos incluir herramientas de instalación y piezas de repuesto.