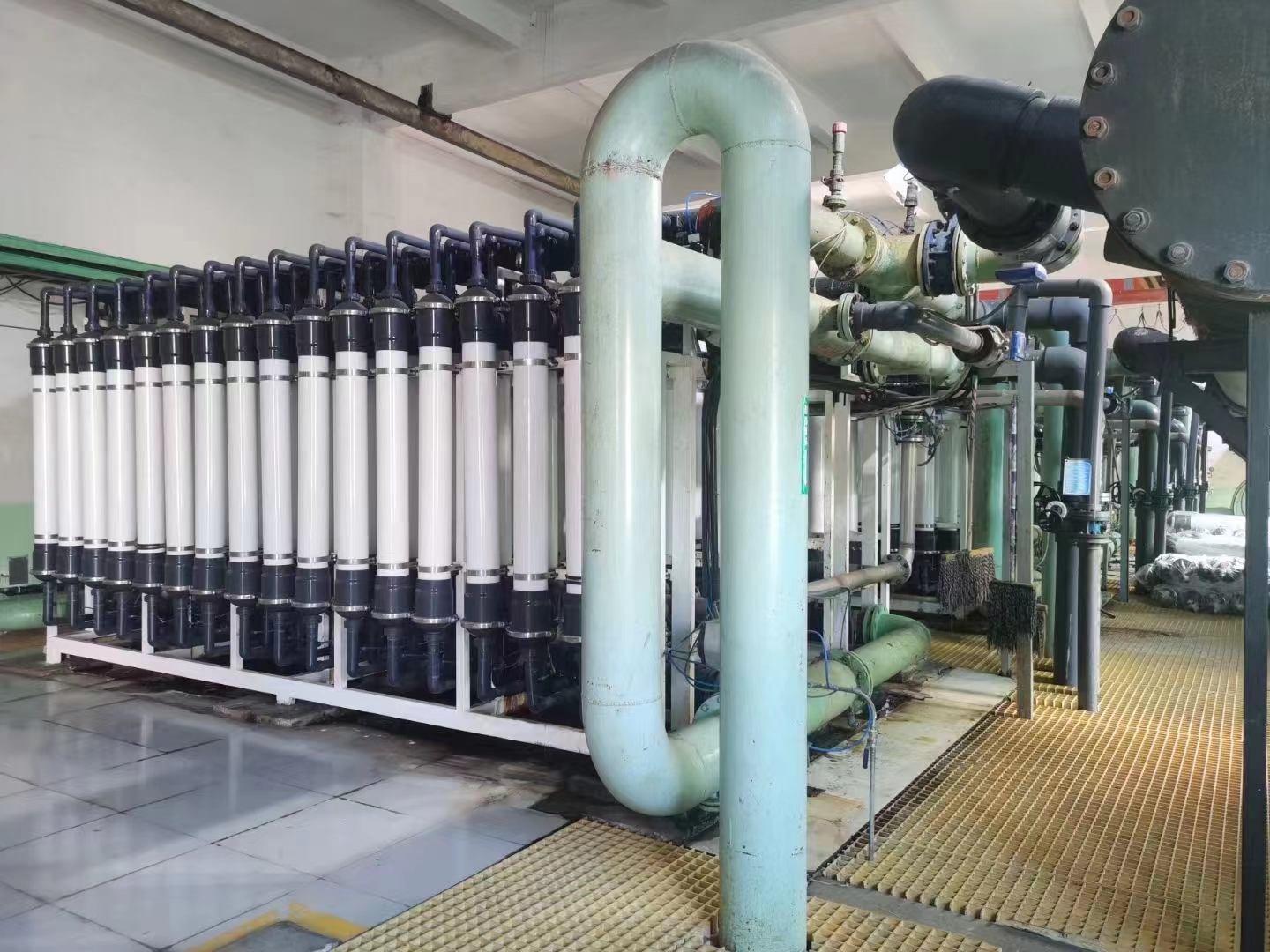

Equipos industriales de ultrafiltración Sistemas UF

Achieve superior water clarity and robust contaminant removal with Stark Water’s Industrial Ultrafiltration Equipment. Our advanced Ultrafiltration Equipment, designed as comprehensive UF Systems, provides highly efficient physical separation for various industrial processes, ensuring consistent water quality and protecting valuable downstream machinery.

Descripción del producto

In demanding industrial landscapes, the consistent availability of high-quality process water is paramount for product integrity, operational efficiency, and regulatory compliance. Untreated or inadequately filtered water can lead to equipment fouling, product defects, and costly downtime. Stark Water’s Industrial Ultrafiltration Equipment offers a sophisticated and highly effective solution to these challenges, providing robust UF Systems specifically engineered for the rigorous demands of various industrial applications.

Industrial Ultrafiltration Equipment: Advanced Physical Separation

Our Ultrafiltration Equipment leverages state-of-the-art UF membrane technology, a highly efficient physical separation process that stands as a cornerstone of modern water treatment. UF membranes feature microscopic pores (typically ranging from 0.01 to 0.1 microns) that act as a barrier, effectively removing a wide spectrum of impurities. This includes suspended solids, turbidity, colloids, bacteria, viruses, and other microorganisms. Unlike conventional filtration methods, industrial UF systems provide a consistent and absolute barrier to these contaminants, ensuring reliable filtrate quality regardless of fluctuations in raw water turbidity. Operating at relatively low pressures, UF is an energy-efficient method for achieving exceptional water clarity and purity on an industrial scale.

Comprehensive UF Systems for Diverse Industrial Needs

Stark Water’s Industrial Ultrafiltration Equipment is designed as comprehensive UF Systems, capable of addressing a broad array of industrial water treatment needs. These systems are highly versatile and can be configured for various applications:

- Superior Pre-treatment for RO Systems: UF is recognized as an ideal pre-filtration stage for Reverse Osmosis (RO) systems. By effectively removing suspended solids, colloids, and microorganisms, it significantly extends the lifespan of sensitive RO membranes, reduces fouling, and minimizes the need for chemical pre-treatment, leading to more efficient RO operation.

- Standalone Process Water Purification: Provides high-quality clarified water for various industrial processes that require low turbidity and microbial loads, such as cooling tower make-up, boiler feed water polishing, and general utility water.

- Wastewater Treatment and Reuse: Crucial for producing high-quality effluent in industrial wastewater treatment plants, making water suitable for safe discharge, irrigation, or industrial reuse applications, contributing to sustainable water management.

- Product Clarification: Used in industries like food & beverage for clarifying juices, beverages, and other liquid products, ensuring clarity and quality.

Our industrial UF systems are built with robust construction materials (e.g., stainless steel, durable polymers) and feature advanced automation for efficient operation, including automated backwash and Clean-in-Place (CIP) cycles, minimizing manual intervention and maximizing uptime.

Parámetros del producto

Stark Water’s Industrial Ultrafiltration Equipment offers robust and efficient UF Systems with customizable specifications. Here are its key technical parameters:

| Parámetro | Especificaciones / Opciones de personalización |

|---|---|

| Palabras clave principales | Ultrafiltration Equipment design and capabilities. |

| System Capacity | Customizable, ranging from 5 m³/hr to 1000+ m³/hr (approx. 22 GPM to 4400+ GPM), depending on industrial application and scale. |

| Filtration Technology | Ultrafiltration (UF) Membrane Filtration. |

| Membrane Type | Hollow Fiber UF Membrane (e.g., PVDF, PES, PAN), chosen based on feed water characteristics and desired permeate quality. |

| Pore Size | Typically 0.01 μm – 0.1 μm (e.g., 0.02 μm), selected for specific contaminant removal (bacteria, viruses, colloids). |

| Presión de funcionamiento | Typically 0.05 – 0.3 MPa (0.5 – 3 Bar / 7 – 43 PSI). Low pressure operation for energy efficiency. |

| Compatibilidad de la fuente de agua bruta | Municipal Water, Well Water, Surface Water (rivers, lakes), Industrial Wastewater, Treated Seawater (as polishing). Customizable. |

| Salida Calidad del agua | Turbidity Reduction: >99%; TSS Reduction: >99%; Bacteria/Virus Removal: >99.9999% (log 6 reduction or higher). SDI < 3 (ideal for RO feed). |

| Sistema de control | Fully Automatic PLC Control with HMI, real-time monitoring of flow, pressure, turbidity. Automated backwash, chemical cleaning-in-place (CIP) sequences. Remote monitoring and SCADA integration capabilities. |

| Fuente de alimentación | 3 Phase (380V/415V/460V, 50Hz/60Hz), customizable as per industrial standards. |

| Material de construcción |

|

| Dimensions | Customized skid-mounted or modular design to fit industrial facility space requirements. |

| Temperatura de funcionamiento | 5°C – 45°C (material dependent for broader range). |

| Certificación | Designed and manufactured to meet relevant international standards (e.g., ISO, CE, ASME, upon request). |

Industria aplicable

Stark Water’s Industrial Ultrafiltration Equipment provides robust and highly efficient UF Systems, making them essential for a broad range of industrial and municipal sectors requiring superior physical separation and advanced water purification. Our Ultrafiltration Equipment is ideal for:

- Municipal Water Treatment: Provides primary purification or robust pre-treatment for drinking water plants, effectively removing turbidity, suspended solids, bacteria, and viruses from various surface water sources to produce safe potable water.

- Reverse Osmosis (RO) Pre-treatment: Essential for large-scale RO systems, offering superior pre-filtration that significantly extends the lifespan of sensitive RO membranes by efficiently removing suspended solids, colloids, and microorganisms.

- Wastewater Treatment & Reuse: Core component in advanced municipal and industrial wastewater treatment facilities (e.g., as part of Membrane Bioreactor (MBR) systems or tertiary treatment), producing high-quality effluent suitable for discharge, irrigation, or industrial reuse, promoting water conservation.

- Food & Beverage Industry: Used for clarification of process water, juices, wine, beer, and other beverages; also for pre-filtration prior to sterile processes, ensuring product clarity and safety at industrial scale.

- Pharmaceutical & Biotechnology: Provides purified water for process use and pre-filtration for sterile applications in manufacturing facilities, ensuring high purity and compliance.

- Industrial Process Water: Supplies clean process water for various manufacturing operations, preventing fouling of equipment, improving product consistency, and reducing chemical consumption across diverse industries.

- Cooling Tower & Boiler Feed Water: Removes suspended solids and microbial load from make-up water, preventing scaling, biofouling, and improving efficiency of large utility systems.

- Mining Operations: For treating large volumes of process water and wastewater containing high levels of suspended solids and colloids.

- Electronics Manufacturing (Pre-UPW): Employed in pre-treatment stages for ultra-pure water (UPW) systems, ensuring removal of particulates to protect downstream purification for sensitive electronics manufacturing.

- Textile & Dyeing Industry: Used for water recycling and treatment of dye baths to remove suspended particles and color at high volumes, facilitating reuse and reducing discharge.

Ventaja Uno

Stark Water’s Industrial Ultrafiltration Equipment offers the significant advantage of superior physical separation, ensuring unmatched industrial clarity and purity for your demanding processes. Our Ultrafiltration Equipment utilizes advanced UF membranes with precise pore sizes (typically 0.01 to 0.1 microns) to effectively remove virtually all suspended solids, turbidity, colloids, bacteria, and viruses from your raw water source. This robust physical barrier consistently produces exceptionally clear and pure filtrate, safeguarding product quality, preventing equipment fouling, and ensuring strict compliance with stringent industrial water quality standards. Operating at lower pressures than RO, it provides an energy-efficient method for achieving high-quality pre-treatment or standalone purification for critical industrial applications, thereby maximizing your operational efficiency and protecting valuable assets.

Ventaja DOS

Our Industrial Ultrafiltration Equipment is distinguished by its robust industrial design and scalable efficiency, translating into exceptional long-term value for your water treatment infrastructure. Engineered for continuous, heavy-duty operation, these UF Systems are built with high-grade materials and industrial-strength components, ensuring extended durability and minimal downtime even in harsh environments. The modular and scalable design allows for flexible customization to meet varying capacities, from a few cubic meters to hundreds per hour, optimizing resource utilization. Automated backwash and Clean-in-Place (CIP) cycles simplify maintenance and reduce labor costs. This combination of rugged construction, high throughput, and efficient operation minimizes maintenance needs, reduces component replacement frequency, and provides a highly reliable and economically sustainable solution for achieving vast volumes of high-quality purified water, ultimately enhancing your overall industrial productivity.

Productos relacionados

Productos relacionados

-

Equipos de ultrafiltración

STARK suppliers Custom Ultrafiltration water treatment equipment 30T UF System

Añadir al presupuesto -

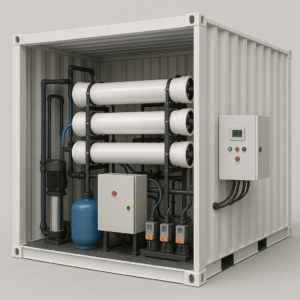

Sistema de ósmosis inversa en contenedor

Sistema de ósmosis inversa en contenedor de 40 pies para proyectos de tratamiento de aguas industriales y de exportación

Añadir al presupuesto

PREGUNTAS FRECUENTES

P1: ¿Cuánto dura el sistema de ósmosis inversa?

La vida útil de un sistema de ósmosis inversa depende de la calidad del agua y del mantenimiento. Normalmente, la membrana dura entre 2 y 3 años, mientras que el sistema en sí puede durar más de 10 años con los cuidados adecuados.

P2: ¿Se puede personalizar el sistema en función de las diferentes condiciones del agua?

Sí, todos nuestros sistemas son totalmente personalizables. Analizamos su informe de aguas y sus necesidades de aplicación antes de ofrecerle soluciones a medida.

P3: ¿Qué normas cumplen los equipos STARK?

Nuestros productos cumplen las normas CE e ISO 9001, y pueden diseñarse para cumplir normativas regionales o estándares industriales específicos si así se solicita.

P4: ¿Cuál es el plazo de entrega de los sistemas de ósmosis inversa STARK?

Los sistemas estándar se envían en un plazo de 7-15 días. Para los pedidos personalizados, el plazo de entrega puede prolongarse hasta 20-25 días en función de la complejidad.

P5: ¿Ofrecen asistencia técnica u orientación para la instalación?

Sí. Proporcionamos documentación técnica completa, asistencia remota por vídeo y podemos enviar ingenieros al extranjero si así se solicita.

P6: ¿Qué incluye su presupuesto?

Nuestro presupuesto incluye el sistema de ósmosis inversa completo, el panel de control, las bombas, las unidades de pretratamiento y todos los accesorios necesarios. Si lo desea, podemos incluir herramientas de instalación y piezas de repuesto.