Depuradora integrada STARK para uso municipal e industrial

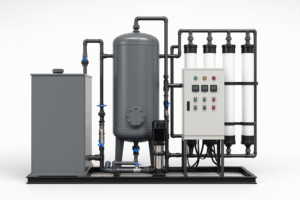

Secure efficient and rapid wastewater management with Stark Water’s STARK Integrated Sewage Treatment Plant. This advanced packaged sewage treatment plant is a complete, pre-assembled solution for municipal and industrial use, offering superior purification, quick deployment, and minimal civil work for diverse wastewater streams.

Descripción del producto

Effective and compliant wastewater treatment is a critical challenge for communities and industries, particularly in areas with limited space, remote locations, or urgent needs for rapid deployment. Traditional, custom-built wastewater treatment plants can be time-consuming and costly to construct. The Stark Water STARK Integrated Sewage Treatment Plant offers a revolutionary solution, providing a complete, pre-engineered, and self-contained system that is ready for quick installation and reliable operation.

The Efficiency of a Packaged Sewage Treatment Plant: Ready for Deployment

Our STARK Integrated Sewage Treatment Plant is the epitome of a modern packaged sewage treatment plant. Unlike conventional plants that require extensive on-site civil works and complex component integration, our packaged solutions are:

- Factory-Assembled and Tested: All components are pre-installed, piped, and wired within a compact, often modular, unit (or series of units) at our factory, minimizing on-site assembly.

- Plug-and-Play: Designed for rapid deployment, these systems typically only require connection to influent, effluent, power, and often a simple foundation, significantly reducing installation time and costs.

- Huella compacta: Engineered to maximize treatment capacity within a minimal physical space, making them ideal for urban areas, resorts, or industrial sites with limited land availability.

- Modular & Scalable: Can be easily scaled up by adding more modules as demand increases, offering flexible solutions for growing populations or industrial expansion.

- Protected from Elements: Often enclosed within a container or robust housing, protecting the sensitive equipment from harsh weather, dust, and unauthorized access.

This integrated approach revolutionizes the speed and simplicity of implementing effective wastewater treatment solutions.

Comprehensive Integrated Sewage Treatment for Municipal & Industrial Use

Our packaged sewage treatment plant provides a comprehensive, multi-stage treatment process within its integrated design, ensuring the production of high-quality effluent suitable for discharge or reuse. It is highly versatile, making it suitable for both municipal and industrial use. Typical integrated stages include:

- Preliminary Treatment: Screening and grit removal to protect downstream processes.

- Primary Treatment: Sedimentation for initial suspended solids removal.

- Biological Treatment: Advanced biological processes (e.g., activated sludge variants, MBR, trickling filters) for efficient removal of organic pollutants (BOD/COD) and nutrients (Nitrogen/Phosphorus).

- Secondary Clarification/Membrane Separation: For solid-liquid separation (either traditional clarifiers or membrane modules for MBR systems).

- Disinfection: Final pathogen removal using UV, chlorination, or ozone before discharge or reuse.

- Sludge Handling: Integrated sludge collection and often dewatering capabilities.

This holistic design ensures that raw municipal sewage or various types of industrial wastewater are treated efficiently to meet stringent environmental regulations, supporting sustainable water management goals.

Reliability, Efficiency, and Sustainable Wastewater Management

The STARK Integrated Sewage Treatment Plant is built for long-term reliability and efficient operation. Its automated controls simplify management, ensuring consistent performance and compliance. By integrating multiple treatment stages, it optimizes energy consumption and chemical usage. This leads to a reduced environmental footprint, lower operational costs, and a more sustainable approach to wastewater management, providing a valuable asset for communities and industries seeking advanced and dependable wastewater solutions.

Parámetros del producto

Stark Water’s STARK Integrated Sewage Treatment Plant is engineered for efficient, robust, and rapidly deployable wastewater treatment. Here are its key technical specifications:

| Parámetro | Especificaciones / Opciones de personalización |

|---|---|

| Palabras clave principales | packaged sewage treatment plant design and capabilities. |

| Treatment Capacity | Customizable, ranging from 10 m³/day to 5,000+ m³/day (approx. 2,640 GPD to 1.3+ MGD). Modular for scalability. |

| Influent Water Source | Municipal Sewage, Domestic Wastewater, Various Types of Industrial Wastewater (e.g., food & beverage, textile, light chemical). |

| Treatment Technologies Integrated |

|

| Effluent Quality (Typical) |

Designed to meet specific discharge limits or reuse standards. |

| Configuración del sistema | Packaged, Skid-mounted, or Containerized (e.g., 20ft/40ft ISO container). Fully pre-assembled and tested. |

| Sistema de control | Fully Automatic PLC Control with HMI, real-time monitoring of key parameters, automated sequences (e.g., backwash, sludge wasting), alarm management. Remote monitoring available. |

| Fuente de alimentación | Trifásico, 380V/415V/460V, 50Hz/60Hz (personalizable). |

| Material de construcción | Tanks/Reactor: Carbon Steel (coated), Stainless Steel (SUS304/316L), FRP, or composite. Piping: UPVC, HDPE, Stainless Steel. |

| Huella | Significantly reduced compared to conventional civil-work plants. |

| Conformidad | Designed to meet stringent local and international discharge standards (e.g., USEPA, EU Directives). Suitable for water reuse. |

| Deployment | Rapid deployment, minimal on-site civil works. |

Industria aplicable

The STARK Integrated Sewage Treatment Plant is a versatile and essential solution for efficient, compliant, and rapidly deployable wastewater management across a broad range of municipal, industrial, and commercial sectors. Its packaged design makes it ideal for:

- Municipal Wastewater Treatment (Decentralized/Rural): For small to medium-sized towns, villages, rural communities, and suburban developments that lack centralized sewerage infrastructure, providing a complete on-site treatment solution.

- Industrial Facilities (Decentralized/Remote): For manufacturing plants, food & beverage processors, chemical factories, and other industries located in remote areas or needing dedicated wastewater treatment for their specific effluents to meet discharge regulations.

- Hotels, Resorts & Tourist Complexes: For large hotels, eco-resorts, and tourism developments in coastal or remote areas, managing sewage and greywater on-site for discharge or reuse (e.g., for landscaping).

- Construction Sites & Worker Camps: Providing temporary or semi-permanent sewage treatment for construction crews, mining camps, and other remote worker accommodations.

- Military Bases & Humanitarian Camps: For rapid deployment of wastewater treatment capabilities in temporary or operational bases, ensuring hygiene and environmental compliance.

- Educational Institutions & Universities: For campus-specific wastewater treatment, particularly for larger schools or universities not connected to municipal systems.

- Shopping Malls & Commercial Complexes: For decentralized wastewater treatment in large commercial centers with high occupancy.

- Hospitals & Healthcare Facilities: Providing on-site sewage treatment, especially for facilities in remote locations or those requiring stringent effluent quality for discharge.

- Agricultural (Specific): For treating wastewater from large-scale livestock farms or agricultural processing units.

- Sporting Venues & Event Centers: For managing wastewater generated during large events or at permanent sports facilities.

Ventaja Uno

Ventaja DOS

Productos relacionados

Productos relacionados

- Equipos de tratamiento de aguas residuales

STARK UASB Reactor anaerobio para el tratamiento de aguas residuales industriales

Leer más

PREGUNTAS FRECUENTES

P1: ¿Cuánto dura el sistema de ósmosis inversa?

La vida útil de un sistema de ósmosis inversa depende de la calidad del agua y del mantenimiento. Normalmente, la membrana dura entre 2 y 3 años, mientras que el sistema en sí puede durar más de 10 años con los cuidados adecuados.

P2: ¿Se puede personalizar el sistema en función de las diferentes condiciones del agua?

Sí, todos nuestros sistemas son totalmente personalizables. Analizamos su informe de aguas y sus necesidades de aplicación antes de ofrecerle soluciones a medida.

P3: ¿Qué normas cumplen los equipos STARK?

Nuestros productos cumplen las normas CE e ISO 9001, y pueden diseñarse para cumplir normativas regionales o estándares industriales específicos si así se solicita.

P4: ¿Cuál es el plazo de entrega de los sistemas de ósmosis inversa STARK?

Los sistemas estándar se envían en un plazo de 7-15 días. Para los pedidos personalizados, el plazo de entrega puede prolongarse hasta 20-25 días en función de la complejidad.

P5: ¿Ofrecen asistencia técnica u orientación para la instalación?

Sí. Proporcionamos documentación técnica completa, asistencia remota por vídeo y podemos enviar ingenieros al extranjero si así se solicita.

P6: ¿Qué incluye su presupuesto?

Nuestro presupuesto incluye el sistema de ósmosis inversa completo, el panel de control, las bombas, las unidades de pretratamiento y todos los accesorios necesarios. Si lo desea, podemos incluir herramientas de instalación y piezas de repuesto.