Sistema de tratamiento de aguas residuales MBR STARK para un efluente de alta calidad

Achieve superior wastewater purification and enable water reuse with Stark Water’s STARK MBR Wastewater Treatment System. This advanced MBR wastewater treatment solution integrates biological degradation with membrane filtration, producing high-quality effluent with a compact footprint, ideal for demanding industrial and municipal applications.

Descripción del producto

Efficient and environmentally compliant wastewater treatment is a growing imperative for industries and municipalities worldwide. Traditional wastewater treatment methods often struggle to meet increasingly stringent discharge standards or the demand for water reuse, while also requiring large footprints. The Stark Water STARK MBR Wastewater Treatment System offers a revolutionary solution, combining biological treatment with advanced membrane filtration to produce exceptionally high-quality effluent with a significantly reduced physical footprint.

MBR Wastewater Treatment: The Power of Membrane Bioreactor Technology

Our MBR wastewater treatment system stands at the forefront of modern biological wastewater purification. MBR (Membrane Bioreactor) technology ingeniously integrates a biological activated sludge process with a membrane separation process (typically Ultrafiltration or Microfiltration membranes). Instead of traditional secondary clarifiers, the membranes directly separate the treated water from the mixed liquor suspended solids (MLSS). This allows for a much higher concentration of biomass (microorganisms) in the biological reactor, leading to:

- Superior Effluent Quality: Produces consistently high-quality effluent with virtually no suspended solids, excellent BOD/COD removal, significant nutrient reduction, and high pathogen removal. This often makes the treated water suitable for direct discharge to sensitive environments or for various water reuse applications.

- Huella compacta: Eliminates the need for large secondary clarifiers, significantly reducing the overall physical footprint of the wastewater treatment plant, making it ideal for urban areas or industries with limited space.

- High Organic Loading Rates: The high biomass concentration allows the system to handle higher organic loads more efficiently than conventional activated sludge systems.

- Stable Operation: The membrane acts as an absolute barrier, preventing sludge bulking issues and ensuring stable operation even under varying influent conditions.

This integrated approach revolutionizes the efficiency and effectiveness of wastewater purification, delivering superior results.

Designed for High-Quality Effluent and Water Reuse

The STARK MBR Wastewater Treatment System is specifically designed to produce high-quality effluent that goes beyond mere discharge compliance, opening up possibilities for water reuse and recycling. The ultrafiltration or microfiltration membranes ensure that the treated water is virtually free of suspended solids, turbidity, and pathogens, making it suitable for:

- Non-potable Reuse: Such as industrial process water, cooling tower make-up, irrigation, or toilet flushing.

- Discharge to Sensitive Waters: Meeting stringent environmental standards for discharge into rivers, lakes, or coastal areas.

- Pre-treatment for Advanced Polishing: Providing an excellent quality feed for further treatment processes like Reverse Osmosis (RO) to achieve ultra-pure water.

Our MBR systems are robustly constructed with durable materials (e.g., stainless steel, corrosion-resistant polymers) and feature fully automated controls for continuous operation, including membrane backflushing and cleaning-in-place (CIP) cycles, ensuring reliable and consistent high-quality effluent production.

Sustainable Wastewater Management with Optimized Sludge Production

Implementing a STARK MBR Wastewater Treatment System signifies a commitment to sustainable wastewater management. MBR technology typically results in lower excess sludge production compared to conventional activated sludge systems. This reduces sludge handling and disposal costs, further enhancing the system’s economic and environmental benefits. Its energy efficiency, enabled by optimized aeration and membrane operation, combined with reduced chemical consumption for disinfection (due to high pathogen removal), makes it a responsible and economically advantageous choice for modern wastewater treatment plants seeking advanced and sustainable solutions.

Parámetros del producto

Stark Water’s STARK MBR Wastewater Treatment System is engineered for robust, high-quality effluent production and compact wastewater treatment. Here are its key technical specifications:

| Parámetro | Especificaciones / Opciones de personalización |

|---|---|

| Palabras clave principales | MBR wastewater treatment design and capabilities. |

| Treatment Capacity | Customizable, ranging from 1 m³/day to 50,000+ m³/day (approx. 264 GPD to 13+ MGD), based on influent flow rate and organic load. |

| Process Type | Membrane Bioreactor (MBR) – Combination of activated sludge biological treatment and membrane separation. |

| Membrane Type | Submerged Hollow Fiber UF or MF Membranes (e.g., PVDF, PES). Outside-in or Inside-out flow. |

| Membrane Pore Size | Typically 0.05 μm – 0.4 μm (for UF/MF membranes used in MBR). |

| Influent Water Source | Municipal Sewage, Industrial Wastewater (with appropriate pre-treatment for large solids). |

| Effluent Quality (Typical) |

|

| Organic Loading Rate (OLR) | Typically 0.5 – 2.0 kg BOD/m³·day (higher than conventional activated sludge). |

| Sistema de control | Fully Automatic PLC Control with HMI, real-time monitoring of MLSS, dissolved oxygen (DO), pH, temperature, flow rates, pressure. Automated membrane cleaning (backflushing, chemical cleaning-in-place – CIP), sludge wasting. Remote monitoring and SCADA integration. |

| Fuente de alimentación | 3 Phase, 380V/415V/460V, 50Hz/60Hz (Customizable). Energy consumption optimized. |

| Sludge Production | Lower excess sludge yield compared to conventional activated sludge. |

| Material de construcción |

|

| Footprint | Significantly reduced compared to conventional activated sludge plants (typically 50-70% smaller). |

| Conformidad | Designed to meet stringent local and international discharge standards (e.g., USEPA, EU Directives). Suitable for water reuse. |

| Operational Flexibility | Resistant to sludge bulking, can handle varying influent loads. |

Industria aplicable

The STARK MBR Wastewater Treatment System is a highly effective and versatile solution for producing high-quality effluent and enabling water reuse across a broad spectrum of industrial and municipal sectors. Its compact footprint and superior performance make it indispensable for:

- Municipal Wastewater Treatment: For towns and cities, particularly in areas with limited land availability or stringent discharge regulations, producing high-quality effluent for environmental discharge or urban reuse (e.g., irrigation, toilet flushing).

- Industrial Wastewater Treatment: Essential for treating complex effluents from various manufacturing processes, including:

- Food & Beverage Industry: Dairies, breweries, slaughterhouses, and food processing, where high BOD/COD removal and consistent effluent quality are needed.

- Pharmaceutical & Chemical Industry: Managing wastewater with high organic content, often aiming for discharge compliance or water reuse.

- Textile & Dyeing Industry: Treating wastewater containing dyes, fibers, and processing chemicals, effectively removing pollutants.

- Pulp & Paper Industry: Managing wastewater with high organic and suspended solids load.

- Oil & Gas Industry: Treating specific types of industrial wastewater (e.g., refinery effluents) for high-quality discharge or reuse.

- Water Reuse & Recycling Projects: A core technology for producing reclaimed water suitable for industrial process water, cooling tower make-up, agricultural irrigation, or even indirect potable reuse, promoting water conservation.

- Hotels, Resorts & Large Commercial Complexes: On-site wastewater treatment in areas without central sewerage, producing high-quality effluent for discharge or non-potable reuse (e.g., landscaping).

- Remote Camps & Mining Operations: Providing compact and efficient wastewater treatment solutions in remote locations, with potential for water recycling.

- Airport & Highway Service Areas: For decentralized wastewater treatment with limited space.

- Marine & Offshore Applications: Compact wastewater treatment for large vessels or offshore platforms.

- Agricultural (Specific): For treating high-strength agricultural wastewater (e.g., from livestock farms) where high effluent quality is required for discharge or reuse.

Ventaja Uno

Ventaja DOS

Productos relacionados

Productos relacionados

-

Equipos de tratamiento de aguas residuales

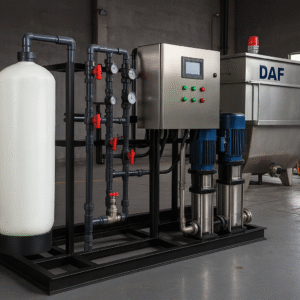

Sistema STARK de flotación por aire disuelto (DAF) para el pretratamiento de aguas residuales industriales

Añadir al presupuesto -

Equipos de tratamiento de aguas residuales

Máquina de deshidratación de lodos STARK para plantas de tratamiento de aguas residuales

Añadir al presupuesto -

Equipos de tratamiento de aguas residuales

Depuradora integrada STARK para uso municipal e industrial

Añadir al presupuesto

PREGUNTAS FRECUENTES

P1: ¿Cuánto dura el sistema de ósmosis inversa?

La vida útil de un sistema de ósmosis inversa depende de la calidad del agua y del mantenimiento. Normalmente, la membrana dura entre 2 y 3 años, mientras que el sistema en sí puede durar más de 10 años con los cuidados adecuados.

P2: ¿Se puede personalizar el sistema en función de las diferentes condiciones del agua?

Sí, todos nuestros sistemas son totalmente personalizables. Analizamos su informe de aguas y sus necesidades de aplicación antes de ofrecerle soluciones a medida.

P3: ¿Qué normas cumplen los equipos STARK?

Nuestros productos cumplen las normas CE e ISO 9001, y pueden diseñarse para cumplir normativas regionales o estándares industriales específicos si así se solicita.

P4: ¿Cuál es el plazo de entrega de los sistemas de ósmosis inversa STARK?

Los sistemas estándar se envían en un plazo de 7-15 días. Para los pedidos personalizados, el plazo de entrega puede prolongarse hasta 20-25 días en función de la complejidad.

P5: ¿Ofrecen asistencia técnica u orientación para la instalación?

Sí. Proporcionamos documentación técnica completa, asistencia remota por vídeo y podemos enviar ingenieros al extranjero si así se solicita.

P6: ¿Qué incluye su presupuesto?

Nuestro presupuesto incluye el sistema de ósmosis inversa completo, el panel de control, las bombas, las unidades de pretratamiento y todos los accesorios necesarios. Si lo desea, podemos incluir herramientas de instalación y piezas de repuesto.