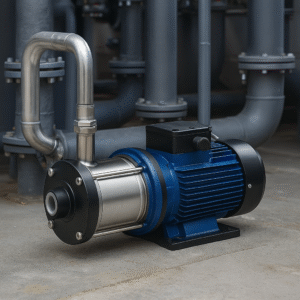

STARK TD pipeline circulating pump

Technical parameterFlow range: 4m³/h~1200m³/hLift range: 4.5m~108mTemperature: -15℃~+110°CAPPLICATIONSHVAC systems District heating Industrial cooling systems Water supply systemsFirefighting systems Water treatment systems Other pressure boosting systems Material:cast iron/stainless steel

Product Description

ubpipipeline circulating pumppeline circulating pumpm pipeline circulating pumpersible pumpSewage treatment equipmentpipeline circulating pumpGuangdong Stark Water Treatment Technology Co., Ltd. is a company that focuses on watertreatment plant and is committed to the research and development, production, sales and after-sales service of environmentally friendly water purification industrial products.The main production and operation of water treatment plant: reverse osmosis system, ultrafiltration system, EDI desalination system, sea water desalination plant, brackish water desalination plant. Products are widely used in electronics, electroplating, power plants, medicine, petroleum, chemical, food and beverage, printing and dyeing indutries. Starck strives to be the forefront explorer of water treatment equipment at home and abroad!Q1: When the middle-opened pump equipped with machine seal needs changing the packing, is the shaft in this pump universal?A: A: Yes, it is universal, but the sealing body, shaft bushing, gland, bolts, fittings and joints must be replaced Q2: Pipe pump is used in the degreasing process before painted, and the shaft seal is often leaking even be replaced for several times. How to solve this problem?A: First of all, confirm leakage part is in the sealing ring or in the sealing ring for corrosion, or in the surface of the friction pair for damage. It is necessary to decide the medium condition of the pump, like whether there are impurities in the medium. Different medium needs corresponding material of corrosion-resisting sealing roller, the medium within impurities grain needs configurating special anti-friction sealing cover.Q3: Where can I see the installation instructions of CDL pump?A: you can find it in the the packing box.Q4: whether the CDL15-10 and CDLF15-10 pump are only different in the base stainless steel, is there any differences in their performance curve?A: CDL (F) series ordinary type and stainless steel type are exactly the same in performance curve.Q5: Is there coupling in CDL15-4 ?A: All CDL(F) series in our company are connected with couplings.Q6: A circulating pump used in our company are seriously leaking. It is unknown whether the pump is come from your company?A: The water pump produced by our company can be judged from three points, 1. Pump invoice number, Q beginning2. Factory number, a total of 10 digits 3. Bar codeQ7: Nowadays, a mechanical seal centrifugal pump is used in playing wastewater use, wastewater containing small molecules of resin, which solidified upon the temperature coming down, which resultedmechanical seal broken down in two days. I would like to ask whether there is a good way to solve this problem.A: Is the machine seal burnt out? If so, it may be caused by the friction burn out due to solidified grease adhering on the gap between the friction pair and preventing circulating water from entering. You can order our special type of knife edge machine seal to solve the problem, thank you.

Product Parameter

The Stark Water STARK TD Pipeline Circulating Pump is engineered for efficient and quiet inline liquid circulation. Here are its key technical specifications:

| Parameter | Specification / Customization Options |

|---|---|

| Core Keyword Focus | pipeline circulating pump design and capabilities. |

| Pump Type | Horizontal or Vertical Inline Centrifugal Pump (Single-Stage or Multistage). |

| Model Series | STARK TD series (specific model numbers vary by flow/head). |

| Construction Material | Pump Casing: Cast Iron (standard), Stainless Steel (SUS304/316 for corrosive liquids/hygiene). Impeller: Stainless Steel, Bronze, or Noryl. Shaft: Stainless Steel. |

| Motor Power | Varies by model and head/flow requirements (e.g., 0.37 kW to 75 kW or higher). |

| Voltage & Frequency | Single Phase 220V/50Hz or Three Phase 380V/50Hz (customizable for 60Hz/other voltages). |

| Flow Rate (Q) | Varies by model (e.g., 5 m³/hr to 1000+ m³/hr). |

| Total Head (H) | Varies by model (e.g., 5m to 100m or more), optimized for circulation. |

| Max. Operating Pressure | Typically 1.0 MPa (10 Bar) to 2.5 MPa (25 Bar), depending on model and application. |

| Inlet/Outlet Size | Flanged connections (PN10/PN16/PN25), sizes from DN25 (1″) to DN300 (12″) or larger. |

| Liquid Temperature | Standard: -15°C to 100°C. High-temperature versions up to 120°C or more available. |

| Seal Type | Mechanical Seal (e.g., Ceramic/Graphite/SiC) for reliable, leak-free operation. |

| Protection Class | IP55 (Motor). |

| Insulation Class | F. |

| Noise Level | Optimized for low noise emission, particularly beneficial for HVAC applications. |

| Installation | Direct inline installation into horizontal or vertical pipelines. |

Applicable Industry

The Stark Water STARK TD Pipeline Circulating Pump is a versatile and essential solution for efficient and quiet liquid circulation across a broad spectrum of industrial, commercial, and residential applications. Its inline design makes it ideal for:

- HVAC Systems: Essential for circulating hot water in heating systems, chilled water in cooling systems, and general water circulation in air conditioning units for commercial buildings, residential complexes, and industrial facilities.

- Hot Water Recirculation: Provides continuous circulation of domestic hot water in large buildings, ensuring instant hot water delivery at faucets and reducing water waste.

- Industrial Process Water Circulation: Circulating various process fluids, cooling water for equipment, and industrial water loops in manufacturing plants, chemical processing, and other industrial settings.

- Water Supply Boosting: Used as an inline booster pump to increase water pressure in specific sections of a pipeline or for smaller-scale water supply systems.

- Fire Fighting Systems (Booster): Can serve as a jockey pump or booster pump to maintain pressure in fire suppression systems.

- Boiler Feed & Condensate Return: Circulating treated water to boilers and handling condensate return in steam systems.

- Agricultural Irrigation: Boosting pressure or circulating water in certain irrigation systems for farms.

- Water Treatment Plants: Used for circulating water within various treatment stages, filter backwash, or transfer between tanks.

- District Heating/Cooling: Integral components in large-scale district energy systems for circulating heated or chilled water.

- General Utility Applications: Any closed-loop system requiring reliable and efficient liquid movement.

Advantage One

Advantage TWO

Related Products

Productos relacionados

FAQ

Q1: How long does the reverse osmosis system last?

The lifespan of a reverse osmosis system depends on water quality and maintenance. Typically, the membrane lasts 2–3 years, while the system itself can last over 10 years with proper care.

Q2: Can the system be customized based on different water conditions?

Yes, all our systems are fully customizable. We analyze your water report and application needs before providing tailored solutions.

Q3: What standards does STARK equipment comply with?

Our products comply with CE, ISO 9001, and can be designed to meet specific regional regulations or industry standards upon request.

Q4: What is the delivery time for STARK RO systems?

Standard systems are shipped within 7–15 days. For customized orders, lead time may extend to 20–25 days depending on complexity.

Q5: Do you provide technical support or installation guidance?

Yes. We provide full technical documentation, remote guidance via video, and can dispatch engineers internationally upon request.

Q6: What is included in your quotation?

Our quotation includes the full RO system, control panel, pumps, pre-treatment units, and all necessary fittings. Installation tools and spare parts can be included upon request.