Industry Challenges in Equipment Cooling & Circulating Water Treatment

- Scaling and Fouling: Frequent scaling, fouling, and corrosion in cooling towers and heat exchangers lead to lower heat transfer efficiency and unexpected shutdowns.

- Variable Source Water Quality: Fluctuations in municipal or well water quality make it difficult to maintain consistent process conditions and often lead to increased chemical consumption.

- Rising Operational Costs: Inefficient water treatment increases chemical, energy, and maintenance costs, impacting the overall profitability of manufacturing operations.

- Strict Compliance Requirements: Modern manufacturing plants face tough environmental discharge standards and must invest in advanced water recycling and zero-liquid-discharge (ZLD) solutions.

- Unplanned Downtime: Equipment failures due to poor water quality result in costly production interruptions and higher maintenance labor.

Typical Application Scenarios

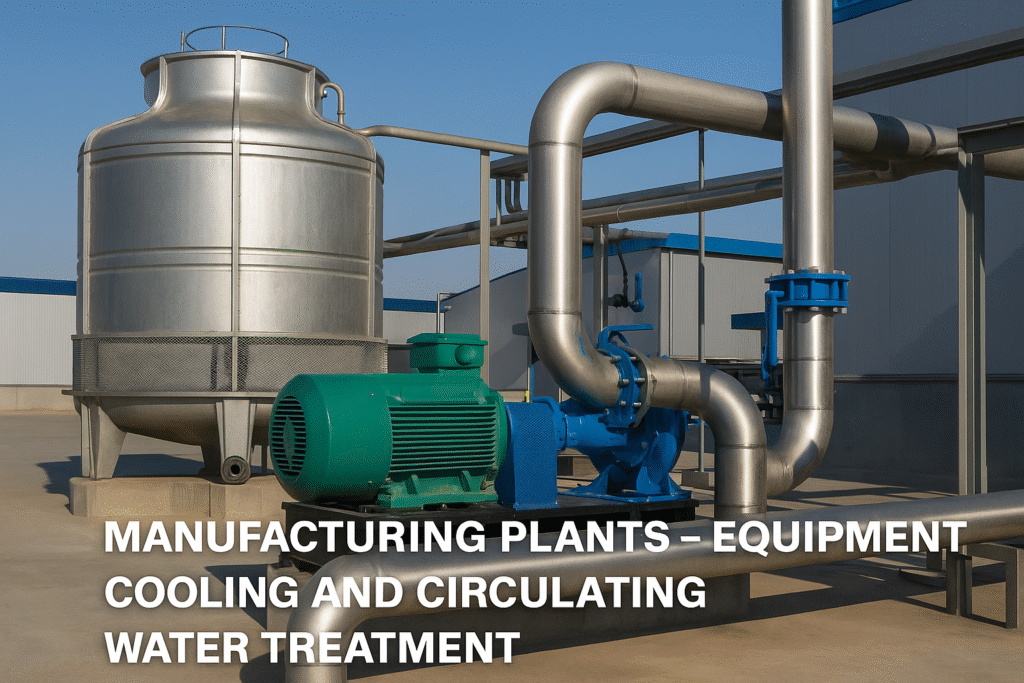

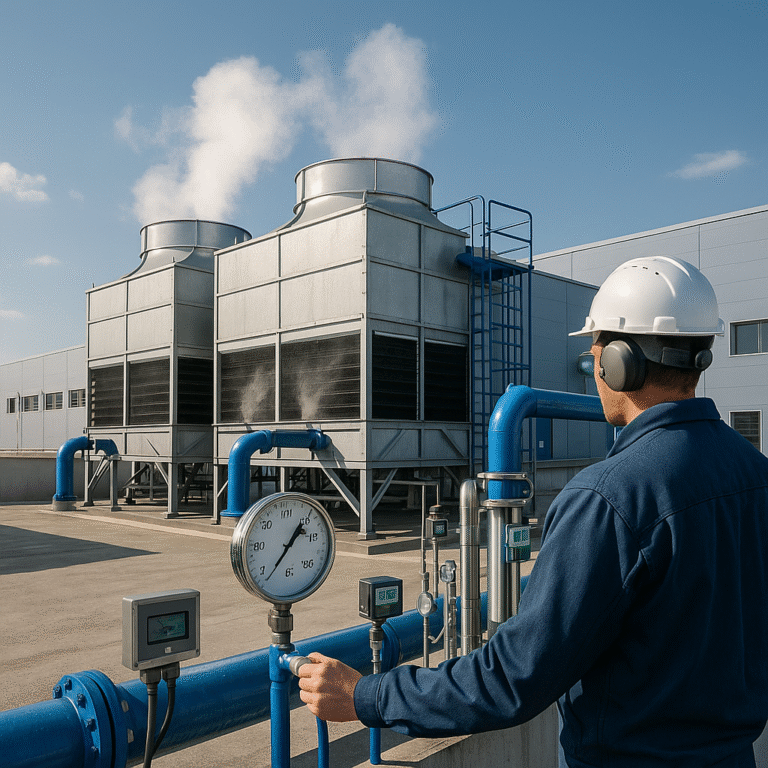

Cooling Towers and Central Chillers

Maintaining low scaling and biofouling risk in open and closed-loop cooling water systems, protecting compressors, condensers, and energy transfer devices.

Production Line Process Water

Supplying stable, high-quality process water for rinsing, cleaning, blending, and manufacturing—minimizing product defects and yield losses.

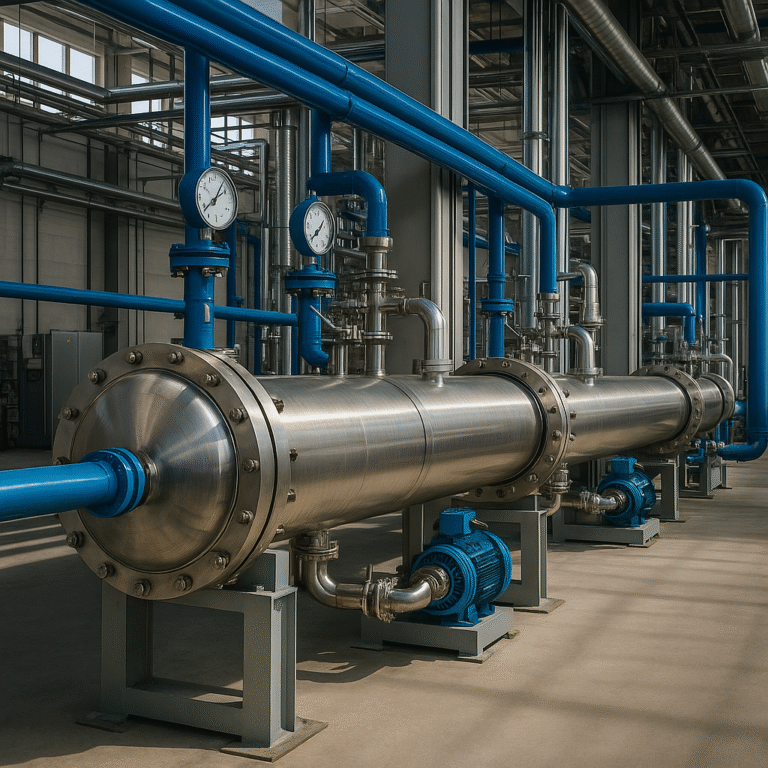

Heat Exchanger Systems

Preventing scale, corrosion, and particulate buildup that compromise heat transfer and drive up maintenance downtime.

Supplementary and Makeup Water Systems

Integrating city water, well water, or reclaimed water sources into recirculating loops with advanced pre-treatment and monitoring.

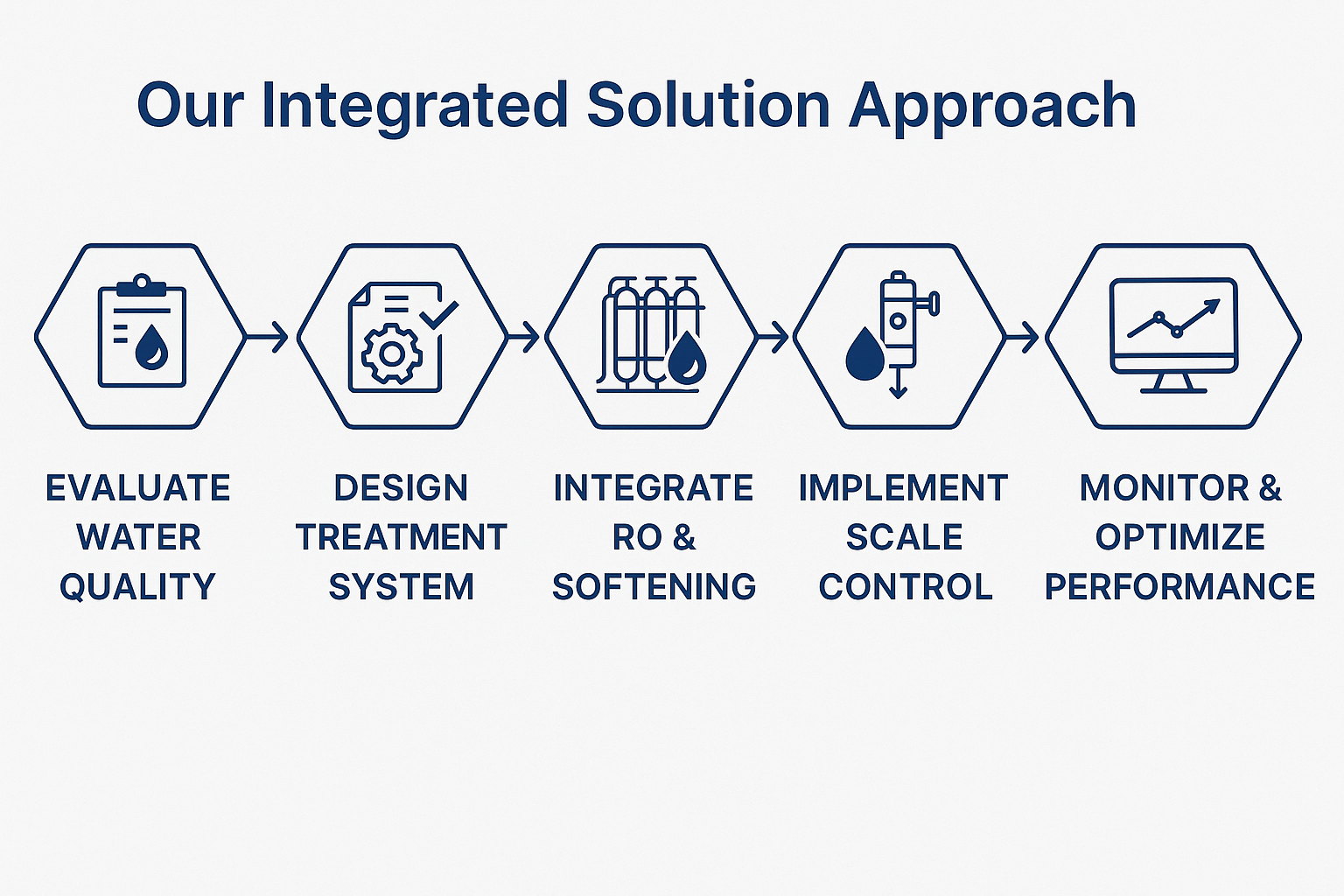

Our Integrated Solution Approach

We design and deliver a fully integrated cooling and circulating water treatment system tailored for each manufacturing environment. Our process typically includes:

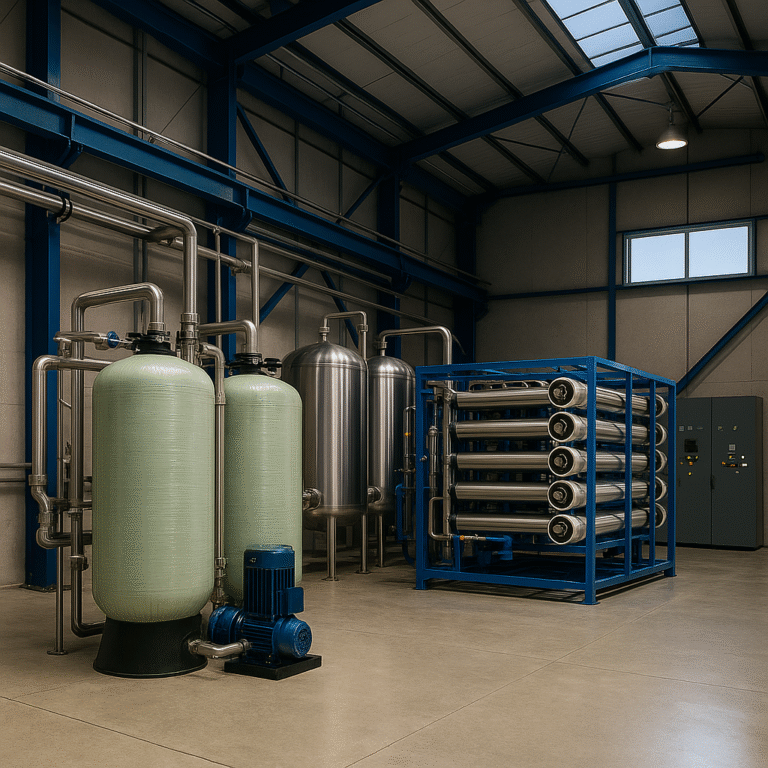

- Pre-Treatment: Removal of suspended solids, iron, and organics using multi-media filters and automatic backwash systems.

- Water Softening: Resin-based softeners to eliminate hardness, prevent scale formation, and reduce chemical dosing.

- Reverse Osmosis (RO) Purification: High-efficiency industrial RO units produce low-conductivity make-up water, enhancing process stability and reducing blowdown volumes.

- Storage and Distribution: Stainless steel tanks and automated pumps maintain hygienic water storage and pressure balance across process loops.

- Smart Dosing and Monitoring: Automated chemical dosing systems and online sensors (pH, ORP, conductivity) ensure precise control, real-time alerts, and compliance reporting.

Our modular, scalable design philosophy allows for easy expansion, future upgrades, and seamless integration with plant automation systems.

-

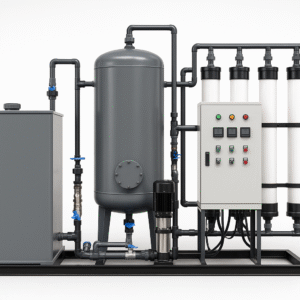

Sistema de ósmosis inversa

2000L RO Purificador Filtro Máquina Industrial RO Filtro RO Equipo de Tratamiento de Agua

-

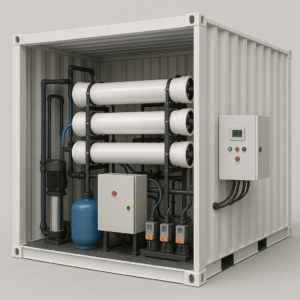

Sistema de ósmosis inversa en contenedor

STARK industrial Containerized RO Purification Systems Containerized Chemical Water Reverse Osmosis System

-

Sistema de ósmosis inversa

30T Gran equipo industrial de ósmosis inversa purificación de agua de desalinización

-

Sistema de ósmosis inversa en contenedor

40FT Containerized RO System for Industrial and Export Water Treatment Projects

-

Equipos de tratamiento de aguas residuales

Depuradora integrada STARK para uso municipal e industrial

-

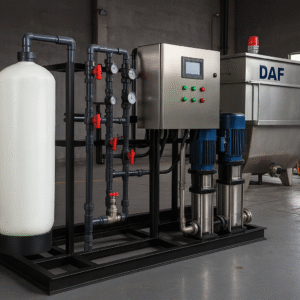

Equipos de tratamiento de aguas residuales

Sistema STARK de flotación por aire disuelto (DAF) para el pretratamiento de aguas residuales industriales

-

Equipos de tratamiento de aguas residuales

STARK UASB Anaerobic Reactor for Industrial Wastewater Treatment