STARK Big Reverse Osmosis Filter System desalination purification treatment plant for sale ro machine price

Elevate your water supply with Stark Water’s Big Reverse Osmosis Filter System. This powerful reverse osmosis filter system is a comprehensive desalination and purification treatment plant, designed for large-scale industrial and municipal needs. Delivering exceptional water quality and efficiency, it’s a top-tier RO machine available at a competitive price.

Description du produit

For large-scale industrial operations, municipalities, and communities facing critical water scarcity or quality challenges, a robust and highly efficient purification solution is essential. The Stark Water Big Reverse Osmosis Filter System is engineered to meet these immense demands, providing a comprehensive and reliable answer for desalination, purification, and overall water treatment. This state-of-the-art reverse osmosis filter system is a strategic investment in securing a sustainable and high-quality water supply.

Large-Scale Desalination and Purification Capabilities

Our Big Reverse Osmosis Filter System is designed for substantial capacity, making it suitable for major industrial needs or serving large populations. It excels as a complete desalination purification treatment plant, capable of transforming highly saline water sources, including seawater and brackish groundwater, into fresh, potable water. Utilizing advanced thin-film composite (TFC) membranes and high-pressure pumping technology, it achieves exceptional contaminant rejection rates, effectively removing up to 99.7% of dissolved salts, minerals, heavy metals, organic compounds, bacteria, and viruses. This comprehensive purification ensures that the treated water consistently meets the most stringent international standards for drinking water or industrial process requirements.

A Complete RO Machine for Sale

This system is presented as a complete RO machine for sale, encompassing all necessary stages for effective purification. It typically includes:

- Advanced Pre-treatment: Multi-media filters (sand, activated carbon), water softeners (if needed), and micron cartridge filters to protect the delicate RO membranes from fouling and extend their lifespan.

- High-Pressure RO Module: Robust membrane pressure vessels housing high-rejection RO membranes, driven by energy-efficient, high-pressure pumps.

- Post-treatment (Optional but Recommended): Depending on desired final water quality, options like UV sterilization for microbiological control, chemical dosing for pH adjustment or disinfection, and advanced deionization (EDI) for ultra-pure water production can be integrated.

- Sophisticated Control System: Fully automated PLC control with Human Machine Interface (HMI) for real-time monitoring of critical parameters, automatic cleaning cycles (CIP), alarm functions, and remote access capabilities for optimal operational management.

The integrated design ensures seamless operation and maximum efficiency, simplifying management of complex large-scale water treatment processes.

Optimized Efficiency and Competitive Price

Investing in the Stark Water Big Reverse Osmosis Filter System is a commitment to long-term efficiency and value. We strive to offer a competitive price for this high-capacity **RO machine**, making advanced water treatment accessible for large-scale projects. The system’s high water recovery rates, coupled with energy-efficient components, translate into lower operational costs and reduced raw water consumption. Furthermore, the robust construction and automated operation minimize maintenance needs and downtime, ensuring a highly reliable and cost-effective solution for securing your purified water supply. It’s an investment that pays dividends through sustainable operations and consistent water quality.

Paramètres du produit

| Paramètres | Spécifications / Options de personnalisation |

|---|---|

| Concentration sur les mots-clés essentiels | Reverse osmosis filter system design and performance. |

| Pure Water Capacity | Customizable, typically ranging from 50 m³/hr to 500+ m³/hr (or higher for very large projects). Specified per client requirements. |

| Raw Water Source Compatibility | Highly versatile for Municipal Water, Well Water, Brackish Water (TDS up to 15,000 ppm), or Seawater (TDS up to 45,000 ppm for SWRO configuration). |

| RO Membrane Type | High-rejection, low-fouling Thin-Film Composite (TFC) RO Membranes (e.g., 8040 series, quantity scaled for capacity/TDS). Specialized SWRO membranes for desalination. |

| High-Pressure Pump | Heavy-duty, high-efficiency, corrosion-resistant centrifugal or positive displacement pumps, often with Variable Frequency Drives (VFDs) for optimized energy use. |

| Pre-treatment System |

|

| Salt Rejection Rate | ≥98.5% – 99.5% (BWRO); ≥99.5% – 99.7% (SWRO) |

| Water Recovery Rate | 40% – 75% (BWRO); 30% – 50% (SWRO) – Dependent on raw water quality, desired recovery, and system design. |

| Output Water Quality | Meets WHO drinking water standards; customized for specific industrial process water needs (e.g., low TDS for boiler feed, ultra-pure water for electronics post-EDI). |

| Alimentation électrique | 3 Phase, 380V/415V/460V, 50Hz/60Hz (Customizable as per regional standards). |

| Système de contrôle | Advanced Fully Automatic PLC Control with HMI (Human Machine Interface), real-time online monitoring of all critical parameters (TDS/conductivity, pressure, flow, temperature), auto-flush, CIP (Clean-in-Place), and comprehensive safety interlocks/alarms. Remote monitoring capability. |

| Matériaux de construction |

|

| Inlet Water Requirements |

|

| Dimensions (Approximate) | Large industrial footprint; fully customized based on capacity and configuration. |

| Operating Temperature | 5°C – 45°C. |

| Certification | Designed to meet relevant international standards (e.g., ISO, CE, ASME, upon request). |

Industrie concernée

- Municipal Water Utilities: Provides immense volumes of safe, potable drinking water for large cities, regions, or communities, especially vital in areas facing severe freshwater scarcity through large-scale desalination projects.

- Large Industrial Parks & Manufacturing Facilities: Supplies high-purity process water for diverse manufacturing operations, including electronics, automotive, textiles, and heavy industries, ensuring product consistency, preventing equipment damage, and meeting stringent quality standards.

- Major Food & Beverage Production Plants: Essential for producing vast quantities of purified water for beverage formulation (bottled water, soft drinks, breweries, dairies), food ingredient processing, and comprehensive cleaning-in-place (CIP) systems, guaranteeing product safety and quality.

- Power Generation & Energy Sector: Critical for boiler feed water purification in thermal and nuclear power plants, cooling tower make-up water, and turbine washing, preventing scaling, corrosion, and improving energy efficiency of high-pressure equipment.

- Pharmaceutical & Biotechnology Giants: Used as the foundational purification stage to generate Purified Water (PW) and pre-treat for Water for Injection (WFI) for drug manufacturing, large-scale bioreactors, and sterile environments, adhering to the strictest GMP standards.

- Mining & Metals Industry: For large-volume process water, mineral extraction, and treatment of challenging water sources (e.g., acid mine drainage), contributing to operational efficiency and environmental compliance.

- Oil & Gas Industry: Provides treated water for injection in oil recovery, fracking operations, and various process applications, often requiring large volumes and robust treatment.

- Chemical Water Treatment Plants (Core Component): Serves as the primary purification unit in comprehensive chemical water treatment plants, providing vast quantities of high-purity water for complex chemical formulations, dilutions, and reducing the chemical load on subsequent treatment steps.

- Wastewater Treatment & Reuse (Advanced Systems): Employed in advanced wastewater treatment facilities to produce high-quality effluent suitable for industrial reuse, agricultural irrigation, or even indirect potable reuse, promoting water conservation.

Avantage 1

Avantage DEUX

Produits apparentés

Produits similaires

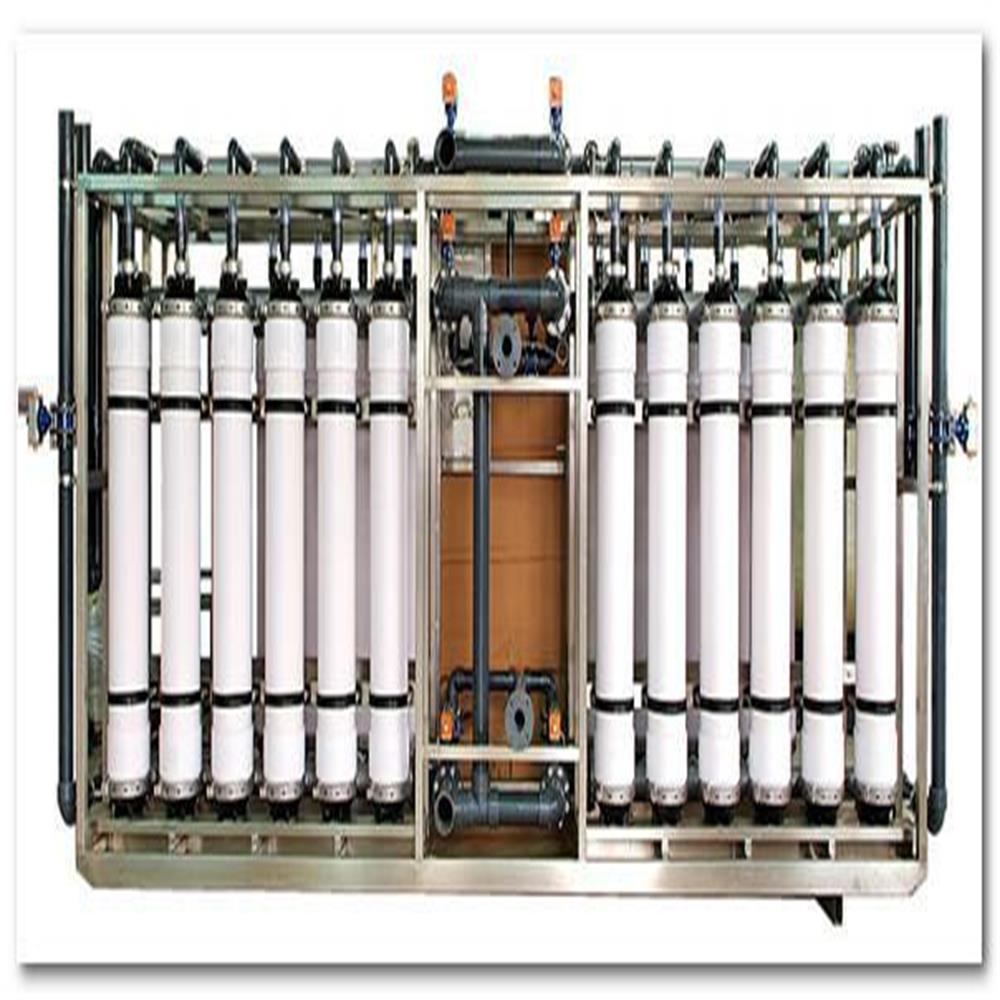

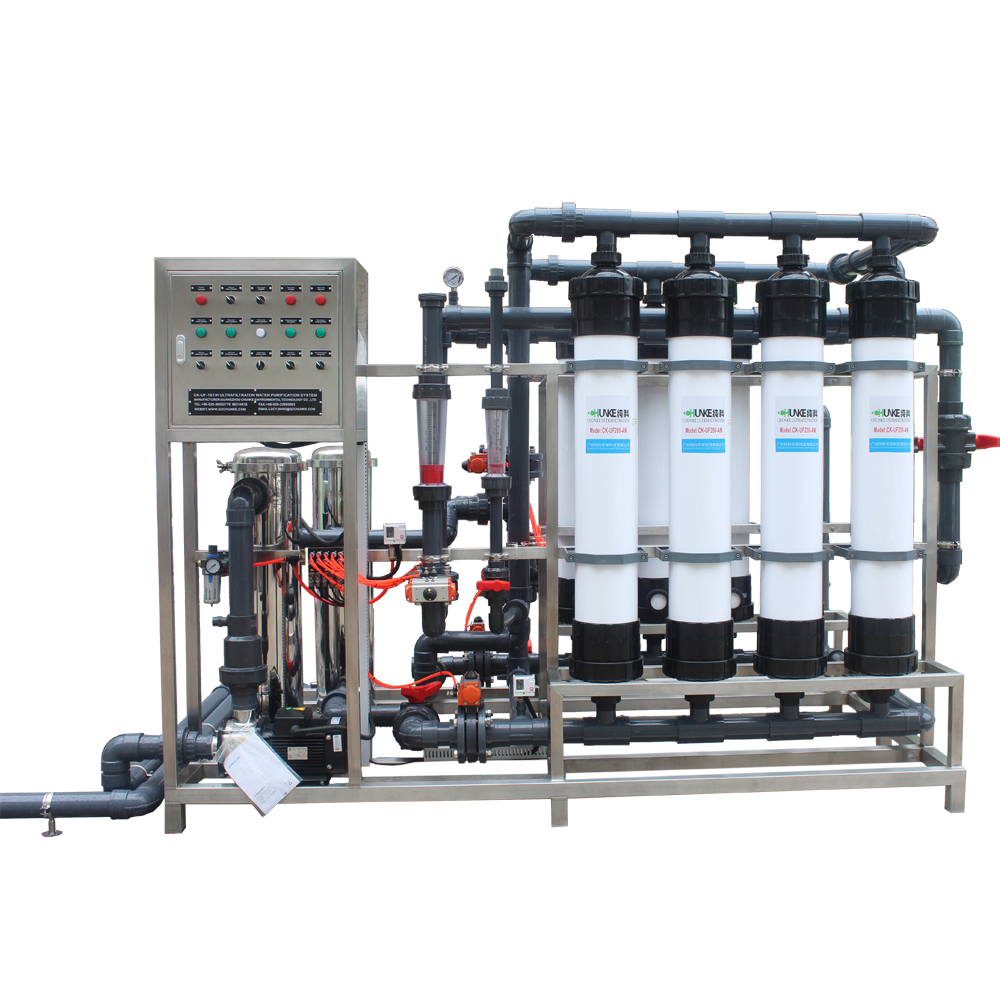

- Équipement d'ultrafiltration

STARK suppliers Custom Ultrafiltration water treatment equipment 30T UF System

Ajouter au devis - Équipement d'ultrafiltration

STARK suppliers Custom Ultrafiltration water treatment equipment 100T UF System

Ajouter au devis

FAQ

Q1 : Quelle est la durée de vie du système d'osmose inverse ?

La durée de vie d'un système d'osmose inverse dépend de la qualité de l'eau et de l'entretien. En règle générale, la membrane dure 2 à 3 ans, tandis que le système lui-même peut durer plus de 10 ans s'il est bien entretenu.

Q2 : Le système peut-il être personnalisé en fonction des différentes conditions de l'eau ?

Oui, tous nos systèmes sont entièrement personnalisables. Nous analysons vos besoins en matière de rapports sur l'eau et d'applications avant de vous proposer des solutions sur mesure.

Q3 : Quelles sont les normes auxquelles répondent les équipements STARK ?

Nos produits sont conformes aux normes CE et ISO 9001 et peuvent être conçus pour répondre à des réglementations régionales spécifiques ou à des normes industrielles sur demande.

Q4 : Quel est le délai de livraison des systèmes STARK RO ?

Les systèmes standard sont expédiés dans un délai de 7 à 15 jours. Pour les commandes personnalisées, le délai peut aller jusqu'à 20-25 jours en fonction de la complexité.

Q5 : Fournissez-vous une assistance technique ou des conseils d'installation ?

Oui. Nous fournissons une documentation technique complète, des conseils à distance par vidéo et nous pouvons envoyer des ingénieurs à l'étranger sur demande.

Q6 : Qu'est-ce qui est inclus dans votre devis ?

Notre devis comprend le système RO complet, le panneau de contrôle, les pompes, les unités de prétraitement et tous les accessoires nécessaires. Les outils d'installation et les pièces de rechange peuvent être inclus sur demande.