Industry Challenges in Equipment Cooling & Circulating Water Treatment

- Scaling and Fouling: Frequent scaling, fouling, and corrosion in cooling towers and heat exchangers lead to lower heat transfer efficiency and unexpected shutdowns.

- Variable Source Water Quality: Fluctuations in municipal or well water quality make it difficult to maintain consistent process conditions and often lead to increased chemical consumption.

- Rising Operational Costs: Inefficient water treatment increases chemical, energy, and maintenance costs, impacting the overall profitability of manufacturing operations.

- Strict Compliance Requirements: Modern manufacturing plants face tough environmental discharge standards and must invest in advanced water recycling and zero-liquid-discharge (ZLD) solutions.

- Unplanned Downtime: Equipment failures due to poor water quality result in costly production interruptions and higher maintenance labor.

代表的なアプリケーション・シナリオ

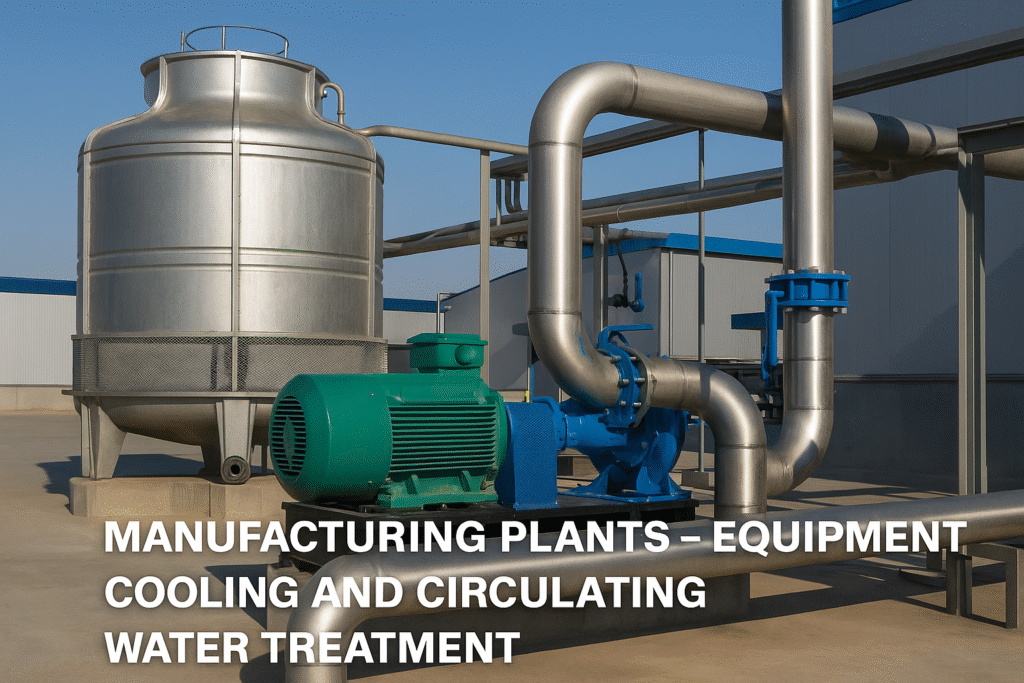

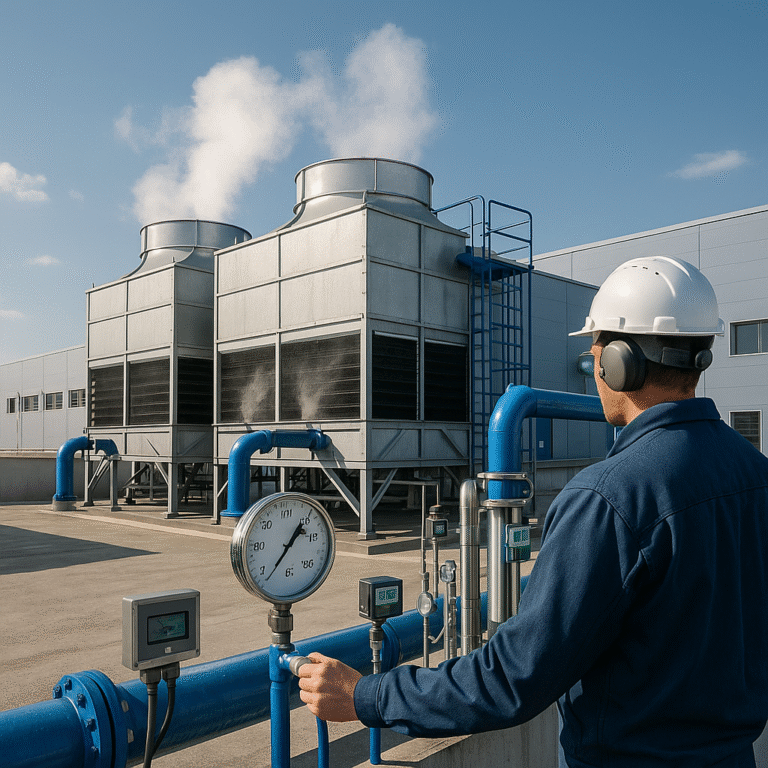

Cooling Towers and Central Chillers

オープンおよびクローズドループの冷却水システムにおいて、スケーリングと生物付着のリスクを低く維持し、コンプレッサー、凝縮器、エネルギー伝達装置を保護する。

Production Line Process Water

すすぎ、洗浄、混合、製造用の安定した高品質のプロセス水を供給し、製品の欠陥や歩留まり低下を最小限に抑えます。

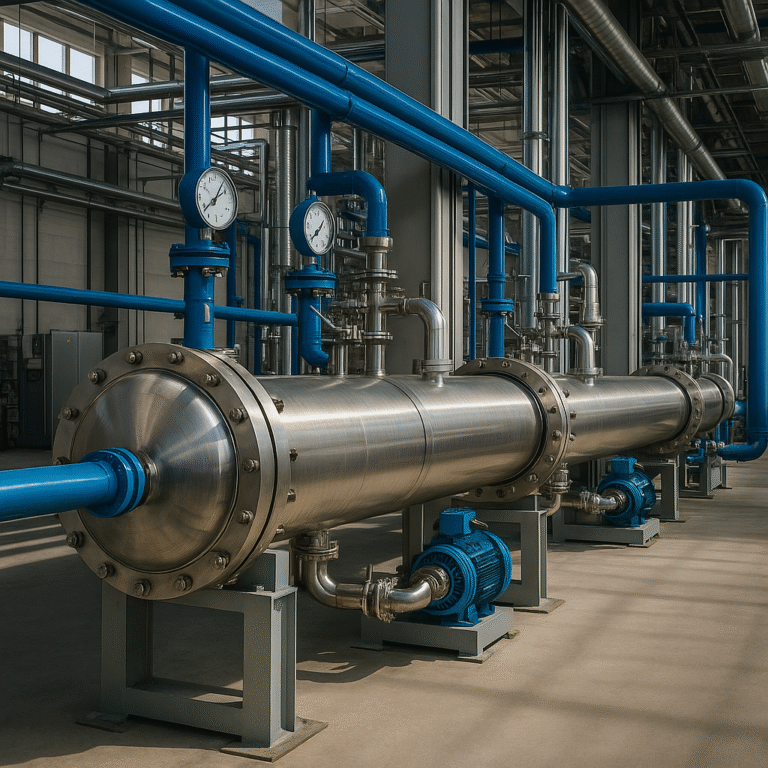

Heat Exchanger Systems

熱伝達を損ない、メンテナンスのダウンタイムを増加させるスケール、腐食、粒子状物質の蓄積を防止します。

Supplementary and Makeup Water Systems

市水、井戸水、再生水の水源を、高度な前処理と監視を備えた再循環ループに統合する。

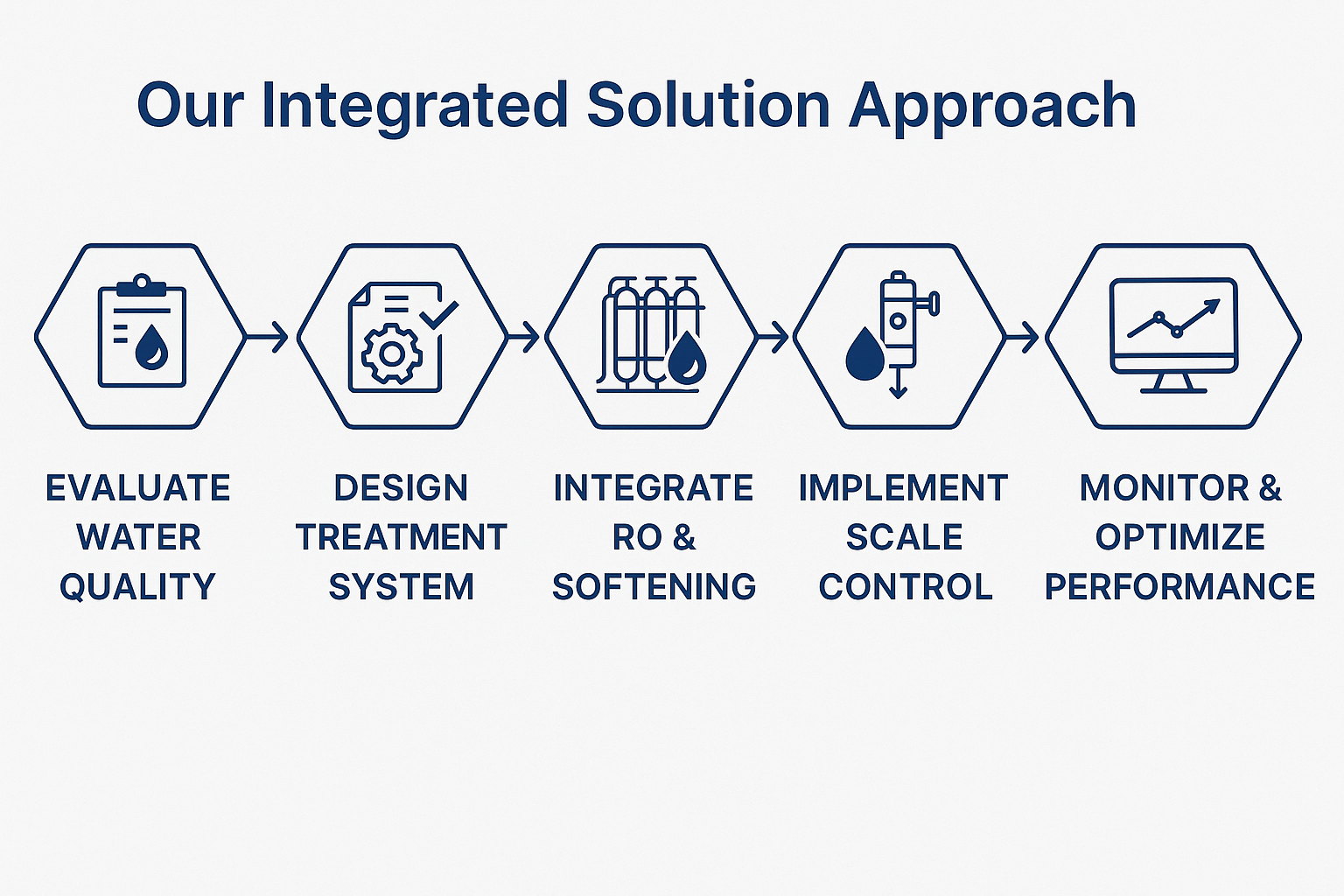

Our Integrated Solution Approach

We design and deliver a fully integrated cooling and circulating water treatment system tailored for each manufacturing environment. Our process typically includes:

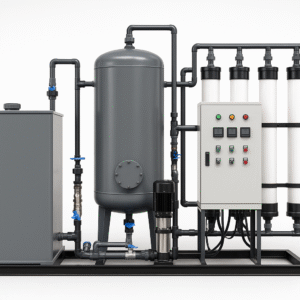

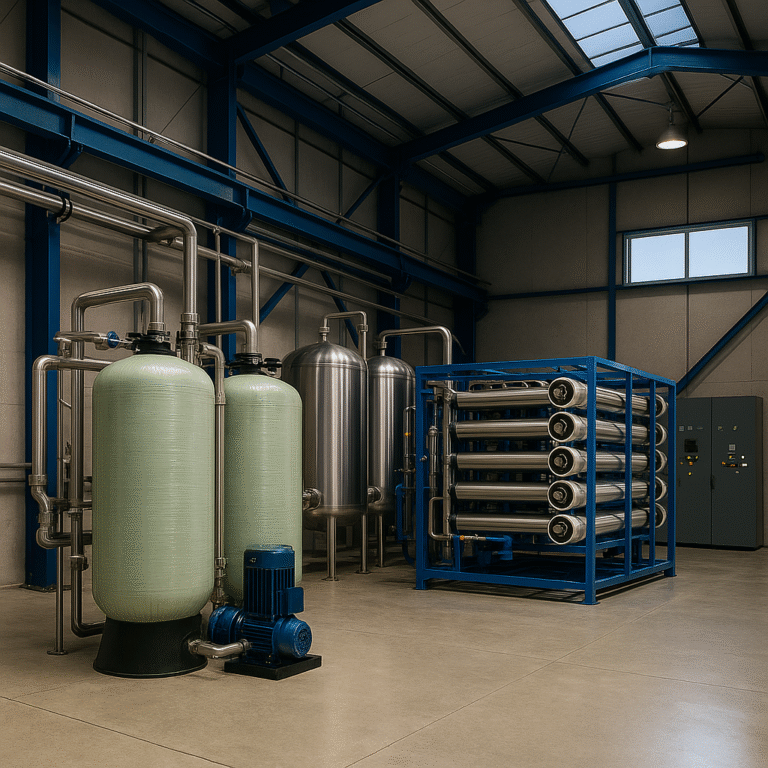

- Pre-Treatment: Removal of suspended solids, iron, and organics using multi-media filters and automatic backwash systems.

- Water Softening: Resin-based softeners to eliminate hardness, prevent scale formation, and reduce chemical dosing.

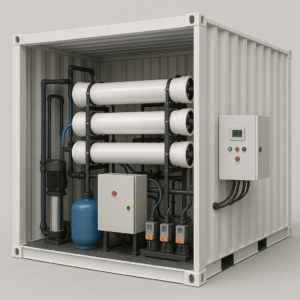

- Reverse Osmosis (RO) Purification: High-efficiency industrial RO units produce low-conductivity make-up water, enhancing process stability and reducing blowdown volumes.

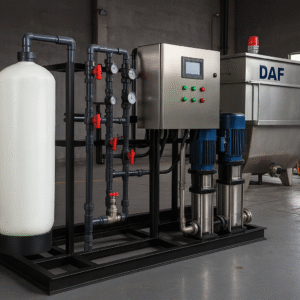

- Storage and Distribution: Stainless steel tanks and automated pumps maintain hygienic water storage and pressure balance across process loops.

- Smart Dosing and Monitoring: Automated chemical dosing systems and online sensors (pH, ORP, conductivity) ensure precise control, real-time alerts, and compliance reporting.

Our modular, scalable design philosophy allows for easy expansion, future upgrades, and seamless integration with plant automation systems.