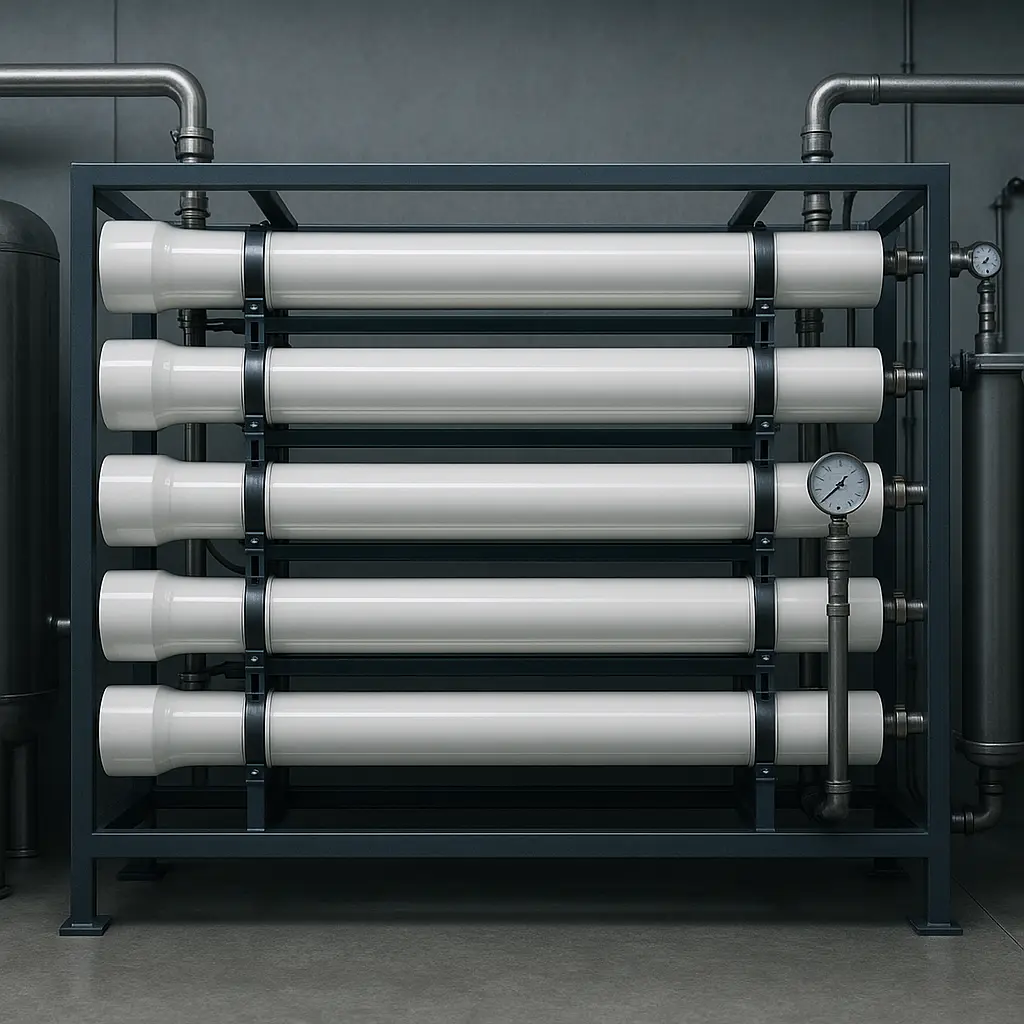

This page is a hands-on reverse osmosis troubleshooting guide for B2B plants. It maps real-world symptoms—low permeate flow, rising differential pressure, and poor product quality—to diagnostics and corrective actions. If you are building an SOP for reverse osmosis troubleshooting, use the symptom map below, then walk through the stage-by-stage checks to confirm the root cause before changing hardware or chemistry.

1) How to use this troubleshooting guide

- Normalize data first (permeate flow, ΔP, salt passage vs. temperature). Compare today vs. baseline.

- Start with safety: depressurize, lockout pumps, and follow vessel OEM instructions for end-cap handling.

- Change one variable at a time: fix pretreatment before polishing. Trend after each change.

- ドキュメント: keep a simple log (feed/conc/permeate, pressures, SDI, CIP dates, chemical lots).

What is reverse osmosis troubleshooting?

In short, reverse osmosis troubleshooting is the structured process of turning plant symptoms into verified causes by normalizing data (flow/ΔP/quality vs. temperature), checking pretreatment first, and testing one change at a time. The goal is stable flux, compliant product water and predictable OPEX—without over-cleaning or chasing noise in instruments.

See the full RO process & O&M guide for baseline set-up and staging rules.

2) Reverse Osmosis Troubleshooting — Symptom Map (Fast Triage)

| 症状 | Likely root causes | First checks |

|---|---|---|

| Low permeate flow | Fouling (SDI/bio), feed deterioration, under-rated pump, permeate backpressure, instrument misread | Normalize flow; read SDI/turbidity; check pump curve and VFD setpoint; verify product line is not restricted |

| Rising ΔP (stage 1 or overall) | Particulate fouling, microbio growth, wrong/failed cartridge filters, coagulant carryover | ΔP by stage, particle counts/SDI, inspect prefilters, review coagulation dosage and filter backwash |

| Poor permeate quality / rising salt passage | Oxidized/damaged elements, O-ring/brine seal issues, mixing of old/new or different element types | Conductivity by stage, check for leaks, inspect brine seals and O-rings, verify element homogeneity |

| Frequent trips or scaling alarms | Recovery too high, wrong antiscalant/dose, analyzer/instrument error | Recalculate LSI/CCPP and recovery; verify antiscalant selection and dilution; calibrate flowmeters |

3) Reverse Osmosis Troubleshooting — Feedwater Deterioration

A stable system can degrade quickly when raw water changes and pretreatment cannot be upgraded in time. Symptoms include fast permeate decline and rising operating pressure/ΔP.

Diagnostics

- Trend SDI/turbidity/COD vs. baseline; take microbial swabs of buffer/feed tanks.

- Check seasonal temperature swings (viscosity) and normalize flows before judging performance.

- Audit pretreatment residence times (contact tank/oxidation) and backwash flows.

Corrective actions

- Upgrade pretreatment (UF/MMF, GAC) or increase chemical dosing window; shorten filter cycles.

- Lower recovery temporarily and add conservative antiscalant limits until fouling is under control.

- Schedule an early stage-1 clean (alkaline + biocide) and reset the baseline after stabilization.

4) Reverse Osmosis Troubleshooting — Pretreatment Performance Degradation

When pretreatment underperforms, SDI/COD break through to the RO and biofouling accelerates. Typical issues: broken CMF/UF fibers, microbial growth in buffer tanks, MMF media channeling, powdered/bioladen carbon.

Diagnostics

- Pressure profile across each pretreatment unit; capture pre- and post-filter SDI.

- Media inspection for mudballing/stratification; ATP or plate counts for tanks and carbon beds.

- Check backwash rates and air-scour effectiveness against OEM specs.

Corrective actions

- Repair/replace broken UF fibers; sanitize tanks; rebed or reclassify MMF/GAC with proper backwash.

- Introduce upstream oxidant/biocide where compatible; verify dechlorination before RO.

- Increase prefilter grade (10→5 μm) and changeout frequency until SDI is stable.

5) Reverse Osmosis Troubleshooting — Cartridge Filter Quality Problems

Poor cartridges deform or miss the micron rating at higher flow, allowing particulates into the RO. Symptoms include rising stage-1 ΔP. Common pitfalls: undersized diameter, soft media, loose end seals.

Checks & fixes

- Verify true outside diameter and end-cap style; ensure housings compress cartridges fully.

- Test with particle challenge; if ΔP is low but SDI after filters is high, swap to depth-graded filters.

- Use absolute-rated (not nominal) cartridges for critical lines; standardize lot tracking.

Need housings and spares? Browse our Water Treatment Accessories catalog.

6) Antiscalant selection, dosing and dilution mistakes

Antiscalant is the “guardian” of stable RO operation, but mis-selection, unreliable metering, over-dilution and contaminated day tanks are common causes of scaling or bio issues.

Diagnostics

- Back-calculate actual recovery vs. setpoint; review chemical densities and pump stroke calibration.

- Inspect day tank hygiene (slime/rust); verify dilution ratios and mixing time.

- Compare the antiscalant’s effective ion window with feed chemistry; check for Fe/Mn interference.

Corrective actions

- Switch to a product matched to your saturation indices; correct dose based on permeate rate, not feed.

- Recalibrate or replace dosing pumps; ban over-dilution that risks phase separation or bio growth.

- Sanitize and cover the day tank; add a Y-strainer on the injection line to catch debris.

When permeate TDS must be blended to spec, try our Permeate Blending Calculator.

7) Other chemical dosing errors

Incorrect flocculants cause severe membrane fouling; too much oxidant damages membranes; excessive reducing agent encourages biofouling.

Do this instead

- Conform flocculant type/dose with jar tests; avoid cationic carryover to spiral-wound elements.

- Control oxidant residual upstream and fully dechlorinate before RO; monitor ORP.

- Size sodium bisulfite to the true oxidant demand; avoid “insurance” overdosing.

8) Instrument errors that mislead operators

Some digital meters read accurately; others drift or allow user parameters that skew readings. If the reject (concentrate) flow reads high, recovery is artificially high and scaling follows; if it reads low, recovery is depressed and ΔP climbs. Large fluctuations make 10–15% trend rules useless.

Corrective actions

- Annual calibration against a primary standard; lock configuration with admin rights.

- Cross-check with clamp-on/volumetric tests; replace meters that can be “tuned” by operators.

- Use stage-wise gauges/flows so recovery and ΔP can be analyzed per stage.

9) Design defects & operation/maintenance (O&M) pitfalls

Several chronic issues trace back to initial design or daily practices: under-head pumps, oxidized membranes, reversed or damaged brine seals, damaged O-rings, mixing old/new or different element types, thrust-ring overlap, over-long vessels leaking to permeate, missing inter-stage gauges, telescoping from high ΔP, permeate backpressure, poor array layout, excessive recovery, particle fouling of stage-1, and contamination during shutdowns.

Design & O&M checklist

- Confirm pump head at worst-case temperature and fouling allowance; leave margin for summer/winter.

- Prohibit oxidants across RO; keep dechlorination healthy; investigate sudden high flux + poor quality (sign of oxidation).

- Inspect brine seals for orientation and integrity; standardize element models per stage.

- Verify thrust-ring position vs. outlet; check vessel length/adapter fit to prevent cross-leak.

- Install inter-stage pressure gauges; limit ΔP to avoid telescoping damage.

- Keep permeate lines free of restrictions; avoid backpressure that suppresses flow.

- Set conservative recovery and adequate element count; redesign arrays that overload leading elements.

- During shutdowns: flush with permeate, add biocide soak where allowed, and restart with low-pressure flush.

10) Cleaning (CIP) triggers & recipes (high level)

- Triggers: normalized permeate ↓ 10–15%, ΔP ↑ 15–20%, salt passage ↑ 10–20%, or bio indicators rising.

- シーケンス: low-pressure flush → alkaline clean (organics/bio) → rinse → acid clean (scale) → rinse → sanitize (if permitted).

- Discipline: log soak times/temperatures; recirculate gently; sample pre-/post-clean to prove recovery.

Always follow the membrane and chemical vendor instructions for temperatures, pH ranges and maximum exposures.Done correctly, reverse osmosis troubleshooting reduces unnecessary cleanings, restores normalized performance, and makes future CIP scheduling data-driven rather than reactive.

11) Preventive maintenance & spares

- Weekly: SDI, stage ΔP, conductivity by stream, chemical day tank hygiene, meter sanity checks.

- Monthly: element mass balance, pump curve verification, cartridge integrity test, alarm review.

- Quarterly: tank/basin sanitation, sample ports maintenance, instrument calibration snapshot.

- Spares: end-cap kits, O-rings, brine seals, interconnectors, absolute cartridges, antiscalant/resins.

For water-quality targets and compliance context, see the WHO drinking-water quality guidelines.

12) Need help with reverse osmosis troubleshooting?

If your normalized KPIs are drifting and root cause isn’t obvious, send us your latest trend sheet (flows, pressures, conductivity, SDI, temperature) and array configuration. Our engineers can review and propose a step-wise fix plan.

Summary

Successful 逆浸透膜のトラブルシューティング follows a repeatable pattern: normalize your KPIs, verify pretreatment, measure stage-by-stage, then adjust recovery, chemistry or hardware only after the cause is proven. If your team wants a printable 逆浸透膜のトラブルシューティング checklist, contact us and we’ll share a one-page PDF with the symptom map and CIP triggers.

よくあるご質問

What’s the fastest way to tell if the problem is pretreatment or RO?

Check SDI before cartridges and ΔP across stage-1. If SDI is high or fluctuating and stage-1 ΔP rises first, fix pretreatment before touching the RO.

Why did permeate flow increase but quality got worse?

Likely oxidation or sealing problems (O-ring/brine seal) causing bypass. Inspect elements and seals; rule out oxidant carryover.

How much antiscalant should I dose?

Match the antiscalant to your feed chemistry and dose on permeate production rate, not feed flow. Avoid over-dilution and keep the day tank clean.

スターク・ウォーター・エンジニアリング・チーム — RO/EDI/MB design, retrofits & commissioning