This hands-on guide explains 限外ろ過膜のファウリング, how to diagnose it fast, and how to recover performance without risking downstream RO. You’ll find symptom maps, a recovery playbook, a prevention program, printable checklists, and FAQs engineers can act on.

Focus process:

UF dead-end & crossflow trains

You’ll learn:

12 root causes → recovery → prevention

Who is it for:

Plant engineers, O&M teams, integrators

Tip: Your Table of Contents plugin will auto-build from the H2/H3 headings below.

1) Snapshot: symptoms & fast triage

| 症状 | What it usually means | First checks (10–15 min) |

|---|---|---|

| Flux decline at same feed | Cake/gel layer growth; temperature drop; instrument drift | Normalize to 25 °C; verify flow & TMP sensors; review last 24 h turbidity/SDI |

| TMP rise by stage | Colloids, biofilm or scale; backwash/CIP cadence too low | Check backwash logs, air scour function, and chemical inventory/strength |

| Filtrate quality drift | Integrity loss or channeling | Run integrity/pressure hold test; inspect vents for air binding |

| Frequent alarms after CIP | Residual chemical release (“sponge effect”) | Rinse and neutralize to spec; confirm zero oxidant before RO |

安全第一だ: De-pressurize, lockout/tagout pumps, wear PPE, follow the membrane OEM chemical limits, and verify zero oxidant before sending filtrate to RO.

2) What UF is & where fouling happens

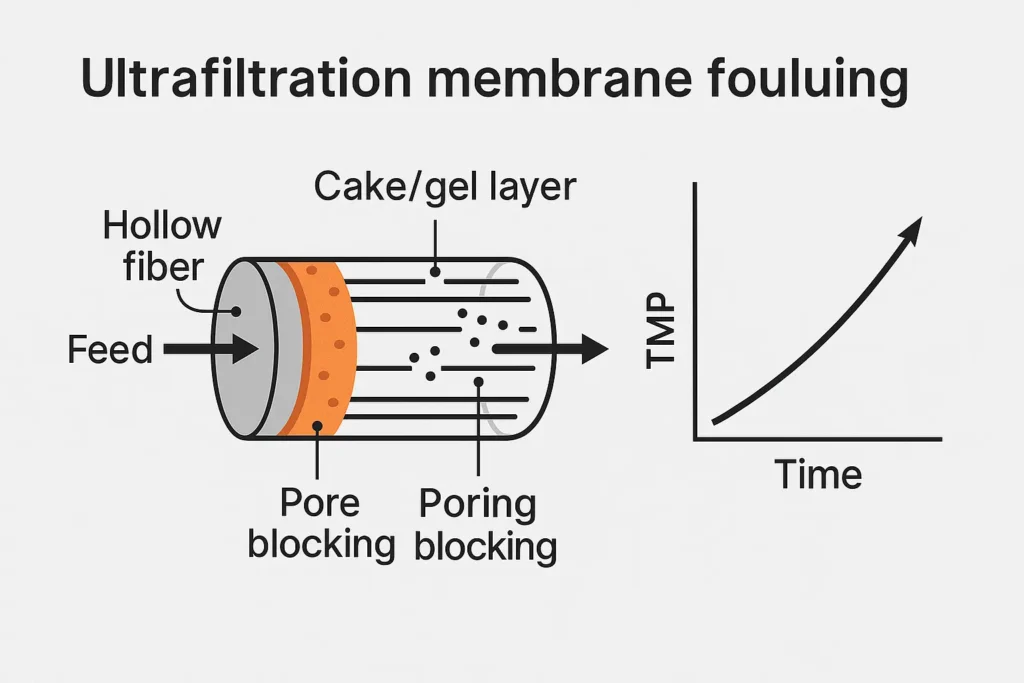

Ultrafiltration separates colloids and microorganisms while allowing salts to pass. In a modern plant the UF stage typically sits before RO/EDI to stabilize SDI/turbidity or after clarification/polishing in food & beverage. Fouling forms on the fiber surface (cake/gel layer), within the pores (pore blocking), or as biofilm when nutrients and warm temperatures align.

3) Ultrafiltration membrane fouling — 12 likely root causes

Water & chemistry

- Low feed temperature → higher viscosity, lower flux at same TMP.

- High SDI/colloids or shock loads from pretreatment upsets.

- Algae/microbial spikes from warm raw water or long residence times.

- Chemical carry-over (coagulants, polymer, oxidants) binding on fibers.

Hydraulics & operations

- Overfeed flow/pressure trying to “chase production.”

- Insufficient crossflow velocity or air scour effectiveness.

- Backwash/CIP intervals too long for the load; skipped soaks.

- Incomplete post-CIP rinsing; pH not neutral when restarting.

Hardware & integrity

- Damaged elements, partial fiber breaks, or poor potting repairs.

- Air binding from bad vents causing localized dryness and scale.

- Instrumentation drift (flow, pressure, turbidity) hiding true TMP/flux.

- Strainers/guards missing or overloaded, letting debris reach modules.

4) Downstream impact (why UF fouling hurts RO & polishing)

- RO stress: SDI creep pushes RO into faster fouling cycles and higher OPEX.

- Chemical shock: retained NaOH/NaOCl can oxidize polyamide if not rinsed to non-detect.

- Quality variability: sporadic fiber leaks cause microbiological risk downstream.

5) Recovery playbook (gentle → aggressive)

Step A — Physical cleaning

- Optimize forward flush and backwash timing; confirm valves and sequences.

- Air scour where supported; verify blower delivery and distribution.

- Reset to OEM-recommended flux (critical flux margin) before chemistry.

Step B — Chemical cleaning (CIP)

- Alkaline clean for organics/biofilm: NaOH with surfactant; optional low-dose NaOCl if OEM allows.

- Acid clean for inorganics/scale: citric or other approved acid with anti-scalant dispersant.

- Method: recirculate 20–40 min → soak 10–30 min → recirculate → thorough rinse to neutral pH & zero oxidant.

Step C — Escalate when TMP isn’t restored

- Repeat targeted chemistry; extend soak; raise temperature within OEM limits.

- Rotate elements or replace modules that no longer recover.

6) Operating mode & design notes: dead-end vs crossflow

| Mode | Pros | Watch-outs for fouling |

|---|---|---|

| Dead-end | Simpler, lower pumping energy | Higher fouling tendency; needs tighter pretreatment and more frequent backwash/CIP |

| Crossflow | Surface shear lowers cake buildup; steadier TMP | Higher recirculation energy; design for velocity windows and CFD-informed manifolds |

7) Integrity management: dealing with hollow-fiber breaks

If integrity tests fail or filtrate quality drifts, isolate the suspect train, plug identified fibers per OEM practice, then re-test. When the percentage of plugged fibers approaches the OEM limit, plan module replacement to avoid hidden bypass and persistent 限外ろ過膜のファウリング.

8) Monitoring & control checklist

| Interval | What to record | Why it matters |

|---|---|---|

| Every shift | Feed temp, turbidity/SDI, filtrate quality, feed/retentate/filtrate flows, TMP by stage | Builds a baseline to detect early fouling |

| 毎日 | Backwash/air scour success and durations; chemical inventory | Prevents spacing out cleans |

| ウィークリー | Integrity test, sensor calibration check, vent/strainer inspection | Validates true performance |

9) Prevention program (what “good” looks like)

- Keep velocity within design windows; avoid running at maximum TMP for long periods.

- Set alarm bands for TMP rise rate and filtrate turbidity; trigger clean/soak automatically.

- Jar tests each season change; track raw-water biology and switch chemistry accordingly.

- Spare parts: seals, strainers, gauges, oxidant/pH test kits, and at least one spare module per skid.

10) Quick BOM & spares list

- Hollow-fiber UF modules (per OEM code), O-rings/seals, strainers/guard filters

- CIP chemicals: alkaline (NaOH + surfactant), acid (citric or approved), neutralizers

- Oxidant, ORP and pH strips/meters; turbidity & SDI kits; calibration liquids

11) FAQs

What does a rising TMP mean?

It signals resistance at the membrane interface or inside pores. Trend TMP at constant temperature and normalized flux to confirm 限外ろ過膜のファウリング versus instrumentation drift.

How do I pick acid vs. alkaline cleaning?

Start with a short alkaline clean for organics/biofilm. If TMP is still high, follow with an approved acid clean for scale. Always rinse to neutral pH and zero oxidant before sending filtrate to RO.

How often should I clean?

Use trend-based intervals. Many plants backwash every 20–60 minutes and perform a short CIP every 8–24 hours of operation, tightening cadence during high-load seasons.

Can I run oxidant through UF?

Only under OEM-approved concentration, pH and temperature limits. Residual oxidant must be non-detect before permeate is allowed to reach RO to avoid polyamide damage.

12) Next steps (RFQ & helpful links)

Share your feed analysis and demand curve—our team will size velocity windows, backwash/CIP cadence, and recommend hygienic tanks & piping for reliable UF performance.

Internal resources: UF cleaning & maintenance - RO troubleshooting guide - DI water storage tank & loop design - Stainless-steel tanks & housings

External references: Water Quality Association - US EPA Water Research

著者 Stark Water Process Engineering Team (process design, O&M, commissioning). Peer-reviewed by: QA/Compliance. Last updated: 20 Oct 2025.

This guide is for trained professionals. Always follow your membrane OEM limits and site safety procedures.