This engineering guide explains how to plan an industrial ダイウォーターシステム—from RO pretreatment and EDI vs mixed bed choices to sizing tables, resistivity targets, polishing steps, instrumentation, and a bill-of-materials template. It is written for factories, laboratories, food & beverage plants, hotels, and surface-treatment shops that need reliable deionized water from wells or municipal supplies.

1) What Is a DI Water System (vs RO & “Ultrapure”)?

A ダイウォーターシステム deionizes water by removing dissolved ions to reach a target resistivity or conductivity. RO (逆浸透) is usually the primary desalting step; electrodeionization (EDI) or a ミックスベッド (SAC+SBA resins) then polishes the RO permeate to very low ionic levels. “Ultrapure” is a use-case label (electronics/analytical labs), not a single machine. Final requirements depend on your industry standard and validation plan.

In practice: wells/municipal feed → pretreatment (particulates, organics, hardness control) → RO → EDI or mixed bed → 紫外線 (microbial/TOC control) → 0.2 μm final filter → storage and recirculating loop (if required).

2) Quality Targets & Conversions (Resistivity ↔ Conductivity)

Specify quality as 抵抗率 (MΩ-cm) または 導電率 (μS/cm). The quick conversion is:

導電率 (μS/cm) = 1 / 比抵抗 (MΩ-cm)

Examples: 18.2 MΩ·cm ≈ 0.055 μS/cm; 1.0 MΩ·cm ≈ 1.0 μS/cm; 0.2 MΩ·cm ≈ 5 μS/cm.

| Application (typical) | Common target | 備考 |

|---|---|---|

| General industrial rinse, boilers makeup (non-high-pressure) | 0.1–1.0 MΩ·cm (10–1 μS/cm) | RO + mixed bed often sufficient |

| Laboratory Type II/III, many F&B utilities | ≥ 1–10 MΩ·cm (≤ 1–0.1 μS/cm) | RO + EDI or high-capacity mixed bed |

| Electronics/analytical Type I | ~18 MΩ·cm (~0.055 μS/cm) | EDI + polishing loop; add TOC control |

Values above are engineering starting points. Use your sector’s standard (e.g., lab water types, corporate SOPs) for formal acceptance criteria.

3) Di Water System Process Trains that Work in Industry

Storage & loop — stainless steel tank with vent filter, spray ball and recirculation to maintain quality.

Pretreatment — multimedia filtration (MMF) and activated carbon; add softening or antiscalant to protect RO; keep SDI low.

RO desalting — core TDS removal; choose element count/staging for temperature, recovery, and fouling risk.

EDI or Mixed Bed polishing — see Section 4 for selection and sizing.

UV (254 nm) そして 0.2 μmファイナルフィルター — control microbes and particulates before points of use.

4) Fast Sizing: RO, EDI or Mixed Bed

4.1 RO Sizing (early estimate)

- Design permeate flow Qp (m³/h) and target recovery R (%) → feed ≈ Qp/R.

- Initial flux for brackish RO: start around 10–15 LMH (L/m²·h) and adjust per membrane datasheet and temperature.

- Pick vessel/element count after vendor selection; small plants often use 2:1 または 2:2 staging; larger trains may use 3:2, etc.

- Keep recovery conservative if fouling/scaling risk is high; validate with antiscalant software or pilot data.

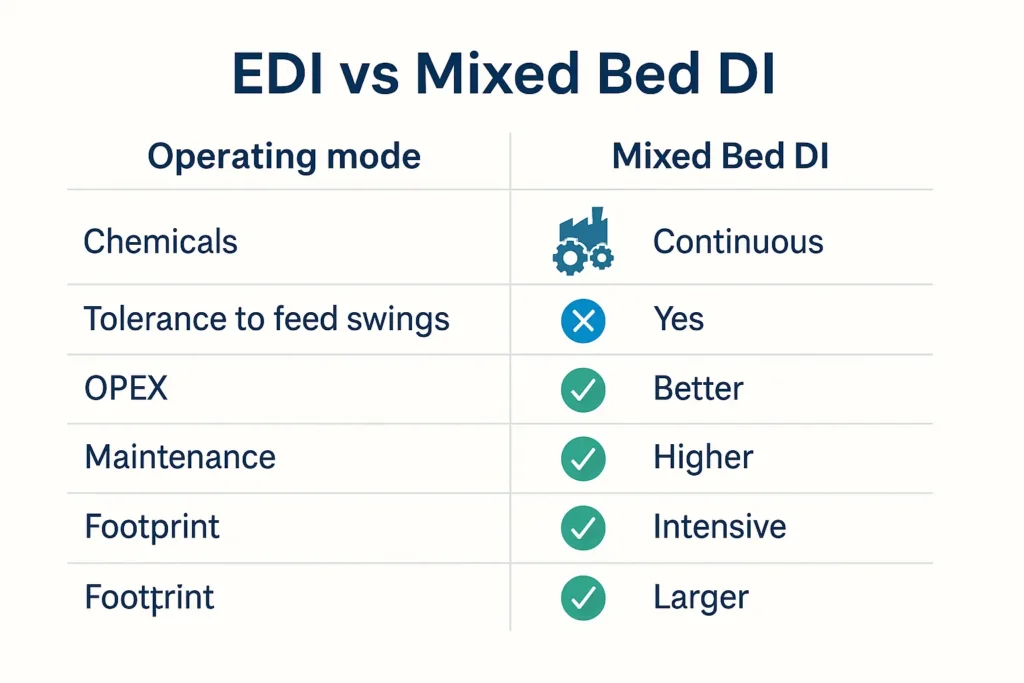

4.2 EDI vs Mixed Bed — Selection

| 基準 | EDI研磨 | Mixed bed polishing |

|---|---|---|

| 動作モード | Continuous, no bulk chemicals | Batch; requires acid/caustic regeneration |

| Feed water window | Works best with stable RO permeate (low hardness/CO2) | More tolerant to feed swings |

| Uptime / staffing | High uptime; skilled commissioning | Simple hardware; periodic regen |

| OPEX | Electric power; periodic clean-in-place | Acid/caustic, neutralization & safety |

| Targets | High resistivity with stable operation | Can reach high resistivity; performance depends on resin & regimen |

4.3 EDI Sizing (rule-of-thumb)

- Confirm RO permeate is within the vendor window (low hardness, low silica/CO2, low TOC).

- Select stack size by 製品流量 (m³/h) そして イオン負荷; apply temperature factor and safety margin for seasonal swings.

- Allow bypass/recirculation for load spikes; instrument with resistivity and flow on each skid outlet.

4.4 Mixed Bed Sizing (rule-of-thumb)

Mixed bed capacity is expressed as equivalents per liter (eq/L). Estimate required resin volume:

Resin volume (L) ≈ [meq/L (ionic load after RO) × flow (m³/h) × run time (h)] ÷ [resin capacity (eq/L)] × safety factor

セット run time to your preferred regeneration interval (e.g., 8–24 h). Use supplier capacity for your resin grade and chemistry.

5) 研磨、保管、流通

- 紫外線 at 254 nm for microbial control; add 185 nm UV if TOC reduction is required by SOP.

- Final filter 0.2 μm at point-of-use or before loop return; sterile vents on storage tanks.

- Storage tank in SS304/316L with spray ball, sloped bottom, and recirculation nozzle.

- Loop in SS or sanitary plastic; size for turbulent velocity to maintain quality.

6) 材料と計装

- Pipework: UPVC/PP for pretreatment; SS316L or sanitary plastics downstream of polishing.

- キーメーター: conductivity/resistivity (at RO permeate, polisher outlet, loop return), TOC (if required), SDI, flow, ΔP.

- Safety: chemical dosing bunds, eyewash, neutralization capacity for mixed-bed regeneration waste.

Related products:

7) Bill-of-Materials (BOM) Template

- 前処理:MMF、GAC、ソフナーまたはアンチスカルファント添加、カートリッジフィルター

- RO skid: high-pressure pump, vessels/elements, interstage instrumentation, CIP ports

- ポリッシャー: EDIスタック または mixed bed resin vessels with regeneration/CIP accessories

- Polishing: 254 nm UV (option 185 nm), 0.2 μm final filter, sanitary valves & gauges

- Storage & loop: SS316L tank with vent filter & spray ball, recirculation pump, loop instruments

- Controls: PLC/HMI, resistivity/TOC transmitters, flow/ΔP, quality interlocks and alarms

- ドキュメントP&ID、レイアウト、FAT/SATチェックリスト、IQ/OQテンプレート

Get an Engineering Proposal

Share your feed analysis and target quality (resistivity or conductivity), product flow, and utilities. We will return a BOM & P&ID recommendation.

8)よくある質問

Is a di water system the same as reverse osmosis?

No. RO removes most dissolved salts; a di water system adds a polishing step (EDI or mixed bed) to reach very low ionic levels.

EDI vs mixed bed—when should I choose each?

Choose 電子データ交換 for continuous operation without bulk chemicals and stable RO permeate; choose a ミックスベッド for wider tolerance to feed swings or when simple batch regeneration fits the site better.

What resistivity should I target?

Use the requirement in your SOP or industry guideline. As a starting point: 1–10 MΩ·cm for many industrial uses; ~18 MΩ·cm for Type I lab water.

Can I retrofit DI after an existing RO?

Yes. Verify RO permeate quality and flow/pressure; then add EDI or a mixed bed skid, plus UV and a 0.2 μm filter before storage/loop.

9)参考文献(外部)

スターク・ウォーター・エンジニアリング・チーム