装置 Dia 200*1100mm イオン交換の樹脂の塩タンク水軟化器システム 1 時間あたりのろ過の植物 500l を柔らかくし、脱塩する産業水

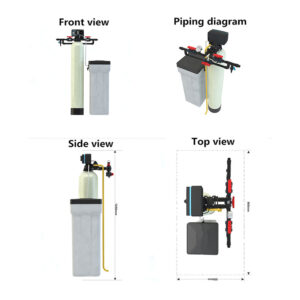

Achieve optimal water quality for your industrial needs with Stark Water’s Industrial Water Softening and Demineralizing Equipment. This compact 500L per hour filtration plant, featuring a Dia 200*1100mm ion exchange resin tank and integrated salt tank, efficiently removes hardness and minerals, protecting your systems and enhancing operational efficiency.

商品説明

For industrial operations, the quality of water used is a critical factor impacting equipment lifespan, energy efficiency, and product consistency. Hard water and high mineral content can lead to costly scaling, corrosion, and reduced performance in boilers, cooling towers, and process lines. The Stark Water Industrial Water Softener and Demineralizing Equipment offers a robust and highly efficient solution, providing consistently softened and demineralized water essential for various industrial applications.

Dual-Action Purification: Softening and Demineralization

This advanced system combines two crucial water treatment processes:

- Water Softening: The primary function is to effectively remove hardness-causing ions like calcium and magnesium through ion exchange. As raw water passes through the specialized resin within the **Dia 200*1100mm ion exchange resin tank**, these hardness ions are exchanged for sodium ions, preventing scale buildup in pipes, heat exchangers, and machinery. This ensures smoother operations, reduced maintenance, and extended equipment life.

- Demineralization (Optional/Complementary): While primarily a softener, the “Demineralizing Equipment” in its name suggests its capability or potential for significant mineral reduction. Full demineralization typically involves both cation and anion exchange resins (or mixed-bed resin) to remove all dissolved mineral salts, producing deionized water. For simpler applications, the softening process significantly reduces a major portion of dissolved minerals (hardness), contributing to a demineralizing effect. If full demineralization is required, additional resin tanks would be incorporated into the system design, ensuring ultra-pure water.

The system’s efficient design supports a continuous flow of **500L per hour**, making it suitable for small to medium-scale industrial processes requiring a reliable supply of treated water.

Compact Design with Integrated Salt Tank

Designed for industrial practicality, this water treatment plant is built with a compact footprint, allowing for flexible installation even in space-constrained environments. A key feature is the integrated **salt tank**, which simplifies the regeneration process. This tank holds the salt (sodium chloride) required to create the brine solution, which periodically recharges the ion exchange resin, ensuring continuous softening and demineralization performance. The robust construction, typically featuring durable FRP tanks and high-quality components, guarantees longevity and reliability in demanding industrial settings.

Automated Operation for Industrial Efficiency

This industrial water softener is designed for automated operation, minimizing manual intervention and optimizing efficiency. Equipped with intelligent control valves, it can be programmed for automatic regeneration cycles (either time-based or volume-based), ensuring that the resin is always ready to treat water without constant oversight. This automation reduces labor costs, ensures consistent water quality, and prevents downtime, allowing your industrial operations to run smoothly and uninterrupted.

製品パラメーター

The Stark Water industrial water softener and Demineralizing Equipment is engineered for efficient and reliable water treatment in industrial settings. Here are its key technical specifications:

- 純水の容量: 500 Liters per Hour (LPH) / Approximately 2.2 Gallons per Minute (GPM)

- System Type: Automatic Industrial Water Softener (Ion Exchange principle), with significant demineralizing effect for hardness. Full demineralization (DI water) requires additional resin beds.

- Ion Exchange Resin Tank: Dia 200*1100mm (Diameter 200mm, Height 1100mm) for the primary resin column (typical dimensions; actual may vary by exact model and capacity).

- Resin Type: High-capacity Strong Acid Cation Exchange Resin (for softening). For full demineralization, Strong Base Anion resin or Mixed Bed resin would be added.

- Salt Tank: Integrated Brine Tank (for salt storage and brine solution preparation).

- Control Valve: Automatic Multi-port Control Valve (e.g., Runxin, Fleck, Clack equivalent), volume or time-based regeneration.

- 入水条件:

- Pressure: 0.2 – 0.6 MPa (2 – 6 Bar / 29 – 87 PSI)

- Temperature: 5°C – 45°C

- Hardness: Typically up to 450 mg/L (as CaCO³), higher requires larger system sizing.

- Free Chlorine: <0.1 ppm (pre-treatment may be required).

- 水質を出力する: Hardness reduced to <0.03 mg/L (as CaCO³), often with significant reduction in other dissolved solids.

- 電源: 220V AC, 50Hz/60Hz (standard for control valve; customizable).

- Connection Type: Threaded (NPT/BSPT) or Flanged connections, suitable for industrial piping.

- 建設資材:

- Pressure Tanks: FRP (Fiber Reinforced Plastic), Dia 200*1100mm or larger depending on exact flow.

- Salt Tank: PE (Polyethylene).

- 配管:UPVCまたはステンレス鋼。

- Frame: Optional, often compact standalone tanks.

- 寸法(概算): Varies based on specific configuration, but designed to be compact.

- Filtration Plant: Refers to the overall system including the softener, making it a complete treatment solution.

適用業種

The Stark Water industrial water softener and Demineralizing Equipment is an indispensable solution for any industrial or commercial operation where hard water or high mineral content can impede efficiency and damage equipment. Its ability to deliver high-quality softened and significantly demineralized water makes it ideal for a diverse range of sectors:

- Boiler Feed Water Treatment: Crucial for preventing scale formation on heat exchange surfaces in industrial boilers, significantly improving energy efficiency, extending boiler lifespan, and reducing blowdown frequency.

- Cooling Towers & HVAC Systems: Reduces scaling and corrosion in cooling loops, optimizing heat transfer efficiency, minimizing chemical usage, and lowering maintenance costs.

- 食品・飲料加工: Provides softened process water for product formulation, cleaning-in-place (CIP) systems, and rinse water, preventing mineral precipitation in products and equipment.

- 繊維・染色業界 Supplies soft water for dyeing and washing processes, preventing mineral stains, ensuring consistent color vibrancy, and improving fabric quality.

- Pharmaceutical Industry (Utility Water): Used for general utility water applications where softened or demineralized water is required, protecting equipment and maintaining hygiene.

- Car Washes & Commercial Laundries: Ensures spot-free rinsing and enhances cleaning efficiency, reduces soap consumption, and extends the lifespan of machinery and textiles.

- Manufacturing & Process Industries: Provides treated water for various production processes, preventing mineral buildup in equipment and ensuring product quality.

- Hospitals & Healthcare Facilities (Non-Critical Areas): Supplies softened water for laundries, dishwashers, and general utility, protecting appliances and ensuring operational efficiency.

アドバンテージ・ワン

アドバンテージ2

関連商品

関連商品

よくあるご質問

Q1: 逆浸透システムの寿命はどのくらいですか?

逆浸透膜システムの寿命は、水質とメンテナンスに左右されます。通常、膜は2~3年、システム自体は適切な手入れをすれば10年以上持ちます。

Q2: 異なる水質条件に応じてシステムをカスタマイズできますか?

はい、当社のシステムはすべてフルカスタマイズが可能です。お客様のウォーターレポートとアプリケーションのニーズを分析し、オーダーメイドのソリューションを提供します。

Q3: STARKの機器はどのような規格に準拠していますか?

当社の製品はCE、ISO 9001に準拠しており、ご要望に応じて特定の地域の規制や業界標準に適合するように設計することができます。

Q4: STARK ROシステムの納期はどのくらいですか。

標準システムは7~15日以内に出荷される。カスタマイズされた注文の場合、リードタイムは複雑さによって20~25日に延びることがあります。

Q5: 技術サポートや設置指導は行っていますか?

はい。完全な技術文書、ビデオによる遠隔指導を提供し、ご要望に応じてエンジニアを海外に派遣することも可能です。

Q6: 見積もりには何が含まれていますか?

お見積もりには、ROシステム一式、コントロールパネル、ポンプ、前処理ユニット、必要な付属品が含まれます。ご要望に応じて、設置用工具やスペアパーツも含まれます。