STARK High-Efficiency 4040 Reverse Osmosis Membrane – Industrial LP4040 RO membrane for Water Purification Systems

STARK High-Efficiency 4040 Reverse Osmosis Membrane – Industrial LP4040 RO membrane for Water Purification SystemsSTARK High-Efficiency 4040 Reverse Osmosis Membrane – Industrial LP4040 RO membrane for Water Purification Systems

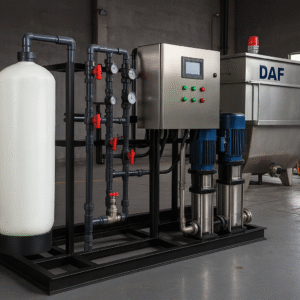

Optimize your industrial water purification with Stark Water’s High-Efficiency 4040 Reverse Osmosis Membrane. This LP4040 RO membrane delivers superior performance, high salt rejection, and energy efficiency, making it an ideal choice for various commercial and industrial RO systems requiring reliable and cost-effective water treatment.

商品説明

The heart of any Reverse Osmosis (RO) system is its membrane, and the quality of this component directly dictates the purity of the water produced, the system’s energy consumption, and its overall operational lifespan. The STARK High-Efficiency 4040 Reverse Osmosis Membrane, specifically the LP4040 RO membrane model, is engineered to deliver exceptional performance for a wide range of industrial and commercial water purification systems. This membrane is a cornerstone for achieving high-quality purified water efficiently and economically.

The Power of the 4040 Reverse Osmosis Membrane

The “4040” designation refers to the standard dimensions of this industrial RO membrane: 4 inches in diameter and 40 inches in length. This standardized size ensures compatibility with most industrial RO pressure vessels, making it a versatile and widely adopted choice. Our 4040 Reverse Osmosis Membrane utilizes advanced thin-film composite (TFC) technology, which is renowned for its superior performance characteristics:

- High Salt Rejection: Effectively removes up to 99% or more of dissolved inorganic salts, heavy metals, organic compounds, bacteria, viruses, and other impurities from the feed water.

- High Permeate Flow: Engineered to produce a significant volume of purified water (permeate) per day, ensuring high output for industrial demands.

- Durability and Longevity: Robust construction designed to withstand continuous operation under various pressure and temperature conditions, ensuring a long service life.

- Chemical Resistance: Offers good resistance to a range of pH levels and cleaning chemicals, facilitating effective membrane cleaning and maintenance.

This membrane is crucial for applications requiring consistent and high-quality purified water, serving as the primary barrier against contaminants.

LP4040 RO Membrane: High Efficiency and Low Pressure Operation

The “LP” in LP4040 RO membrane stands for “Low Pressure,” which is a key advantage for operational efficiency and cost savings. Low-pressure RO membranes are designed to achieve high permeate flow and excellent salt rejection at significantly lower operating pressures compared to standard RO membranes. This translates directly into:

- Reduced Energy Consumption: Lower operating pressure means less power is required for the high-pressure pump, leading to substantial energy savings and lower electricity bills.

- Lower Capital Costs: Can sometimes allow for the use of smaller, less powerful pumps, potentially reducing initial equipment investment.

- Extended System Lifespan: Reduced stress on pumps and other system components due to lower operating pressures can contribute to a longer overall system lifespan and reduced maintenance.

Despite operating at lower pressures, the LP4040 RO membrane maintains its high rejection capabilities, ensuring that the quality of the purified water remains uncompromised. This balance of efficiency and performance makes it an economically attractive choice for a wide array of commercial and industrial water purification systems.

Reliable Performance for Diverse Water Purification Systems

The STARK High-Efficiency 4040 Reverse Osmosis Membrane is a reliable and high-performing component suitable for integration into various water purification systems. Whether for drinking water production, industrial process water, or pre-treatment for ultra-pure water systems, this LP4040 RO membrane delivers consistent, high-quality results, contributing significantly to the efficiency and effectiveness of your water treatment operations.

製品パラメーター

Stark Water’s High-Efficiency 4040 Reverse Osmosis Membrane (LP4040 RO membrane) is engineered for optimal performance in industrial water purification systems. Here are its key technical specifications:

| パラメータ | 仕様/カスタマイズ・オプション |

|---|---|

| コア・キーワード・フォーカス | 4040 Reverse osmosis membrane design and capabilities. |

| Membrane Type | Low Pressure (LP) Thin-Film Composite (TFC) Polyamide. |

| Model Series | LP4040 (Low Pressure, 4-inch diameter, 40-inch length). |

| Standard Dimensions | Diameter: 4.0 inches (101.6 mm); Length: 40 inches (1016 mm). |

| Active Membrane Area | Typically 85 – 90 ft² (7.9 – 8.4 m²), varies by specific model. |

| Permeate Flow Rate | Typically 2,000 – 2,500 GPD (Gallons Per Day) / 7.6 – 9.5 m³/day (at standard test conditions: 2,000 ppm NaCl, 150 psi, 25°C, pH 7.5, 15% recovery). Actual flow varies with feed water quality, temperature, and pressure. |

| Stabilized Salt Rejection | Typically ≥99.5% (at standard test conditions). |

| Minimum Salt Rejection | Typically ≥99.0% (at standard test conditions). |

| Max. Operating Pressure | Typically 600 psi (4.14 MPa). |

| Max. Operating Temperature | Typically 45°C (113°F). |

| Max. Feed Silt Density Index (SDI) | SDI < 5. |

| Chlorine Tolerance | < 0.1 ppm (continuous, requires pre-treatment for chlorine removal). |

| pH Range (Continuous Operation) | 2 – 11. |

| pH Range (Short-term Cleaning) | 1 – 13. |

| Max. Feed Water Turbidity | 1.0 NTU. |

| Feed Water Connection | Standard 1.125″ (28.6 mm) male adapter. |

| Application Focus | Industrial and Commercial Water Purification Systems. |

適用業種

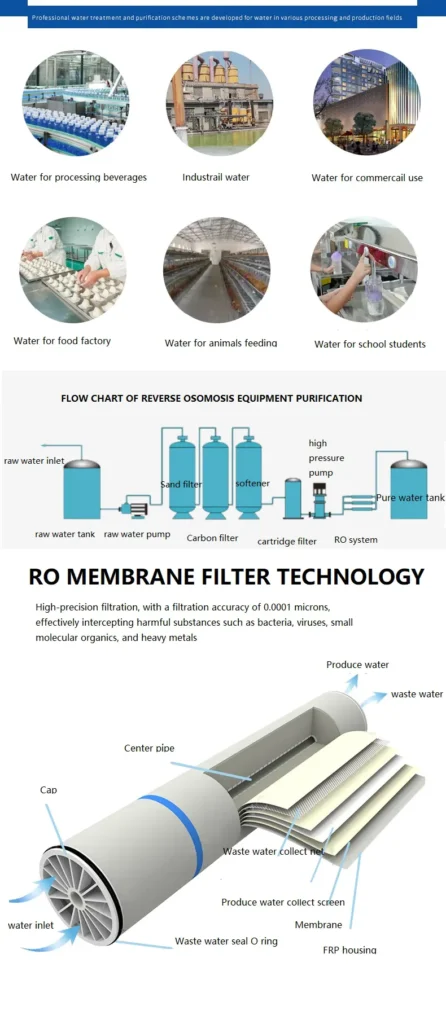

The STARK High-Efficiency 4040 Reverse Osmosis Membrane (LP4040 RO membrane) is a versatile and essential component for a wide array of industrial and commercial water purification systems, where efficient and high-quality purified water production is critical. Its applications span numerous sectors, including:

- Commercial & Industrial RO Systems: The primary application for producing purified water for various industrial processes, general utility, and drinking water.

- Bottled Water & Beverage Production: Essential for purifying source water to meet stringent quality standards for bottled water, juices, soft drinks, beer, and spirits, ensuring product consistency and taste.

- Food Processing: Used for process water, ingredient preparation, washing, and cleaning-in-place (CIP) systems, where high-purity water is required for hygiene and product quality.

- Hotels, Resorts & Hospitals: Providing high volumes of purified water for drinking, cooking, laundry, and general utility, enhancing guest/patient experience and operational efficiency.

- Laboratories & Research Facilities (Pre-treatment): As a robust pre-filter for producing Type II or Type I laboratory-grade water, protecting downstream DI or EDI systems.

- Boiler Feed Water Pre-treatment: Reduces TDS and hardness in boiler feed water, preventing scaling and corrosion in low to medium pressure boilers, improving efficiency and extending equipment life.

- Cooling Tower Make-up Water: Reduces mineral buildup in cooling towers, minimizing blowdown and chemical usage.

- Car Washes & Auto Detailing: Producing spot-free rinse water to prevent water spots and streaks on vehicles.

- Greenhouses & Hydroponics: Providing purified water for plant nutrient solutions, ensuring optimal growth and preventing mineral buildup.

- Pharmaceutical (Non-WFI): For producing purified water for general utility, cleaning, and non-critical processes, as a pre-treatment for higher purity systems.

- Textile & Dyeing Industry: Used for process water to ensure consistent dye quality and prevent mineral staining on fabrics.

アドバンテージ・ワン

アドバンテージ2

関連商品

関連商品

よくあるご質問

Q1: 逆浸透システムの寿命はどのくらいですか?

逆浸透膜システムの寿命は、水質とメンテナンスに左右されます。通常、膜は2~3年、システム自体は適切な手入れをすれば10年以上持ちます。

Q2: 異なる水質条件に応じてシステムをカスタマイズできますか?

はい、当社のシステムはすべてフルカスタマイズが可能です。お客様のウォーターレポートとアプリケーションのニーズを分析し、オーダーメイドのソリューションを提供します。

Q3: STARKの機器はどのような規格に準拠していますか?

当社の製品はCE、ISO 9001に準拠しており、ご要望に応じて特定の地域の規制や業界標準に適合するように設計することができます。

Q4: STARK ROシステムの納期はどのくらいですか。

標準システムは7~15日以内に出荷される。カスタマイズされた注文の場合、リードタイムは複雑さによって20~25日に延びることがあります。

Q5: 技術サポートや設置指導は行っていますか?

はい。完全な技術文書、ビデオによる遠隔指導を提供し、ご要望に応じてエンジニアを海外に派遣することも可能です。

Q6: 見積もりには何が含まれていますか?

お見積もりには、ROシステム一式、コントロールパネル、ポンプ、前処理ユニット、必要な付属品が含まれます。ご要望に応じて、設置用工具やスペアパーツも含まれます。