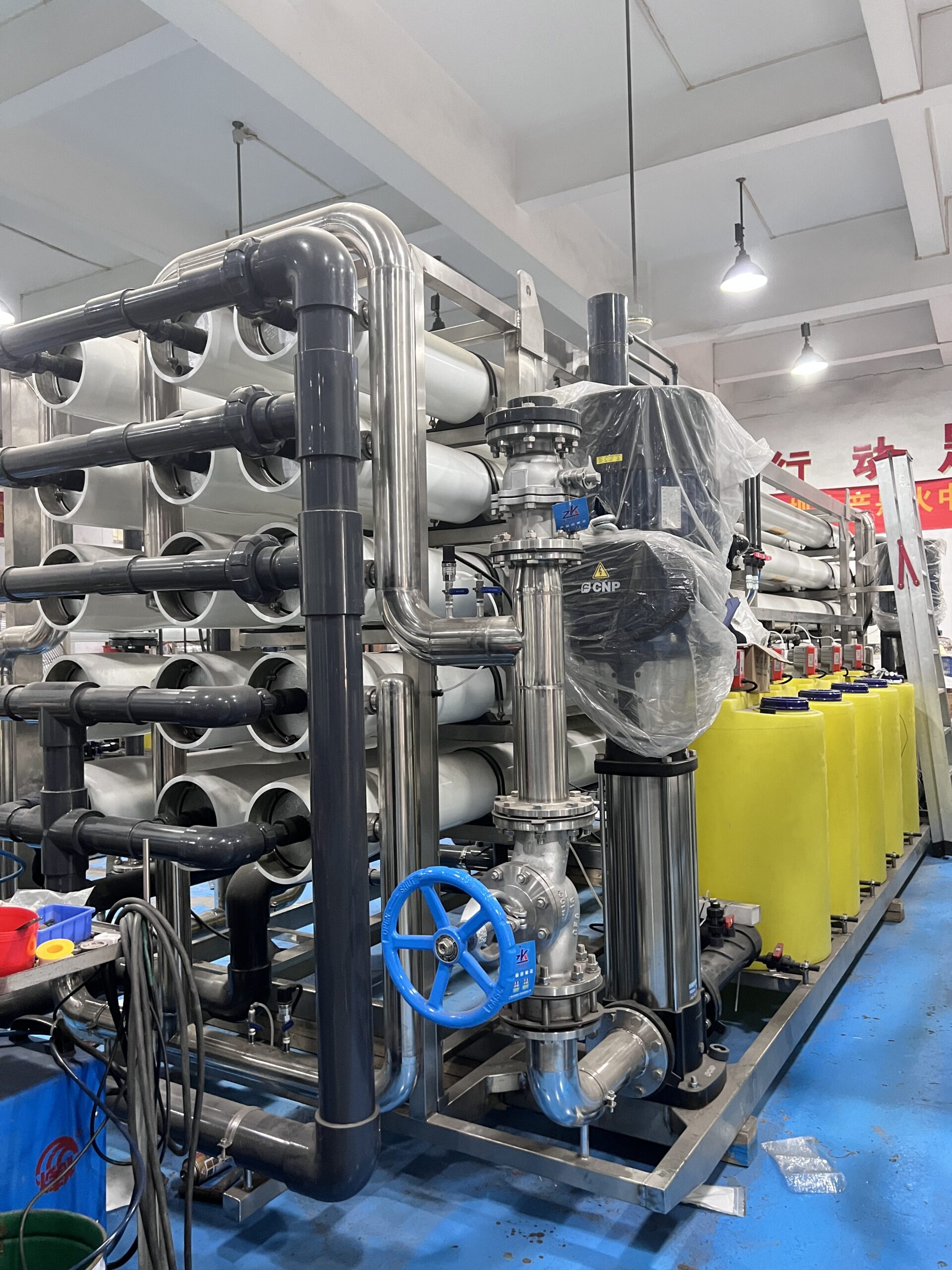

STK Odm 30T Stainless Steel Pure Water Equipment Sea water purification Best Reverse Osmosis System Chemical Water Treatment Plant

Experience large-scale water purification with Stark Water’s STK Odm 30T Stainless Steel Pure Water Equipment. This best reverse osmosis system is a robust 逆浸透システム engineered for high-volume sea water purification and integration into industrial chemical water treatment plant operations, delivering superior purity and durability.

商品説明

For industrial and municipal entities grappling with immense demands for high-purity water, especially from challenging sources like seawater, a truly robust and high-capacity solution is indispensable. The STARK STK Odm 30T Stainless Steel Pure Water Equipment stands as the ultimate answer. This meticulously engineered **reverse osmosis system** is designed for the most demanding large-scale applications, delivering unparalleled purification efficiency and reliability, whether for critical industrial processes or extensive potable water supply.

Massive Capacity & Unmatched Purity from a Best Reverse Osmosis System

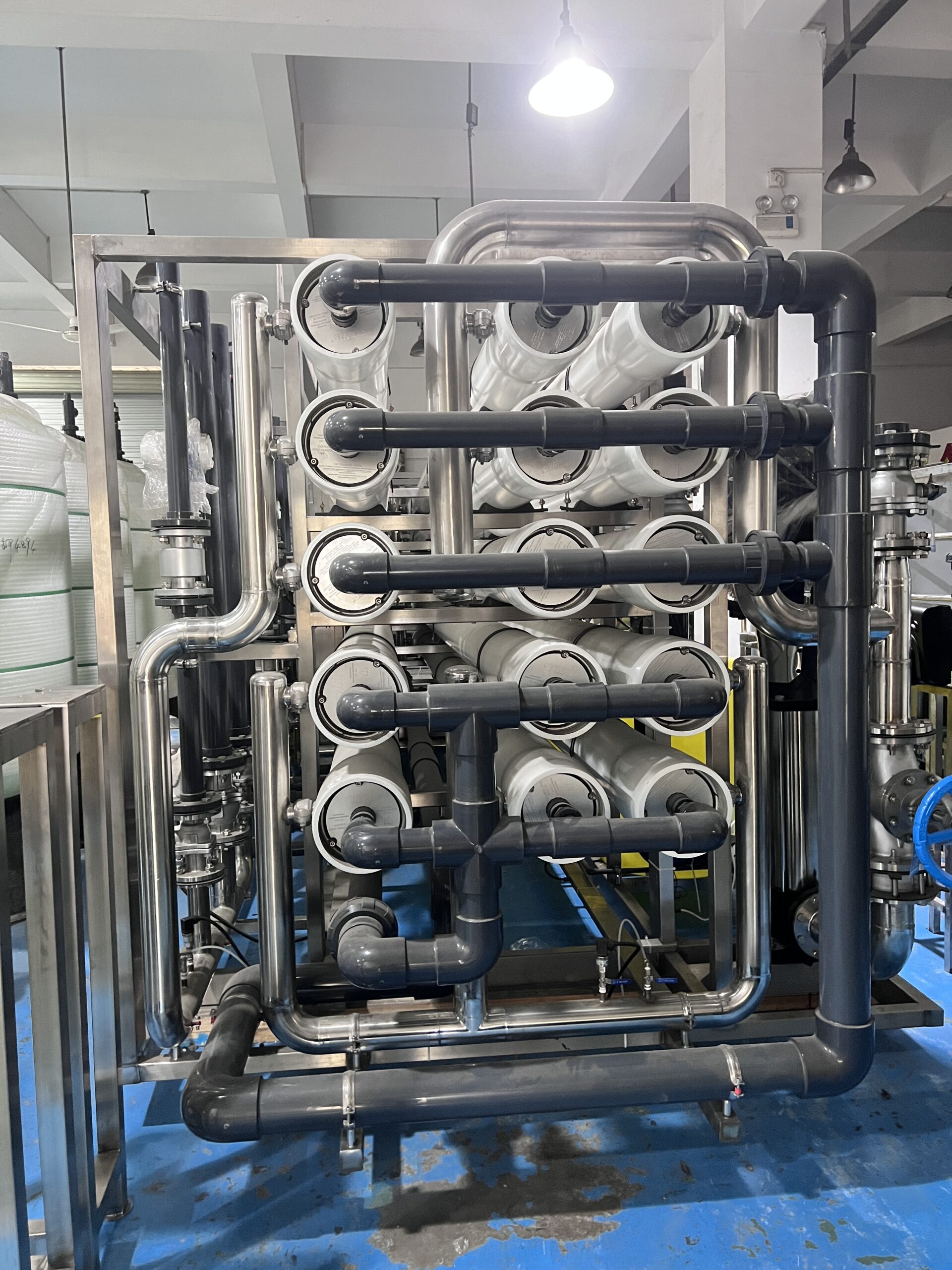

The “30T” in its designation signifies an impressive capacity of **30 tons per hour (30,000 liters per hour or 30 m³/hr)**, placing this system firmly in the realm of large-scale industrial and municipal water treatment. This high-volume output ensures a consistent and abundant supply of purified water, capable of meeting the rigorous demands of extensive production lines, large communities, or complex industrial facilities. Our STK 30T system leverages the most advanced **reverse osmosis technology**, utilizing high-rejection thin-film composite (TFC) membranes and precision components to effectively remove up to 99.7% of dissolved salts, minerals, heavy metals, organic compounds, bacteria, and viruses from diverse raw water sources. This makes it truly a **best reverse osmosis system** for achieving superior water quality.

Robust Stainless Steel Pure Water Equipment for Longevity

Durability and hygiene are paramount for large-scale water treatment infrastructure. This **reverse osmosis system** is distinguished by its **stainless steel pure water equipment** construction. Utilizing high-grade SUS304 or SUS316L stainless steel for critical components, including piping, frames, and pressure vessels, ensures exceptional corrosion resistance, even when treating highly aggressive feedwaters like seawater. Stainless steel’s inherent hygiene also prevents bacterial growth and facilitates easy cleaning, safeguarding the purity of the treated water. This robust, corrosion-resistant design guarantees an extended operational lifespan, significantly reducing maintenance costs and ensuring reliable performance in the harshest industrial environments.

Versatile: From Seawater Desalination to Complex Chemical Water Treatment Plants

The **STARK STK Odm 30T** system boasts extraordinary versatility. It is explicitly designed for **sea water purification**, capable of transforming highly saline ocean water into fresh, potable water or high-quality process water, a critical solution for water-scarce regions and coastal industries. As an **ODM (Original Design Manufacturer)** product, it offers comprehensive customization to perfectly match your specific feed water characteristics, desired product water standards, and unique site requirements. This adaptability makes it an ideal core component for a complete **chemical water treatment plant**, where it provides the primary purification stage before further specialized treatments. Its high efficiency in removing a vast array of contaminants reduces the chemical and energy burden on subsequent purification steps, contributing to an overall more economical and environmentally responsible plant operation.

製品パラメーター

| パラメータ | 仕様/カスタマイズ・オプション |

|---|---|

| コア・キーワード・フォーカス | 逆浸透システム デザインとパフォーマンス。 |

| 純水容量 | 30 m³ per Hour (30,000 Liters Per Hour / approx. 132 GPM) – Representing “STK 30T”. Custom capacities available. |

| 原水の水源適合性 | Municipal Tap Water, Well Water, Brackish Water (TDS up to 10,000 ppm for standard BWRO), or Seawater (TDS up to 45,000 ppm for SWRO configuration). |

| RO膜タイプ | High-rejection Thin-Film Composite (TFC) RO Membranes (e.g., 8040 series, quantity sized for capacity/TDS). Specifically SWRO membranes for seawater. |

| 高圧ポンプ | Heavy-duty, energy-efficient, corrosion-resistant centrifugal or positive displacement pump (e.g., Grundfos, Danfoss, CNP), sized for specific flow and high pressure requirements (often multi-stage). |

| 前処理システム |

|

| 塩分除去率 | ≥98.5% – 99.5% (for BWRO); ≥99.5% – 99.7% (for SWRO) |

| 水回収率 | 50% – 75% (BWRO); 30% – 50% (SWRO) – Dependent on raw water quality and system design. |

| 出力 水質 | TDS <100 ppm (for drinking water/process); significantly lower for high-purity applications after post-treatment (e.g., for EDI feed). Meets WHO standards for drinking water. |

| 電源 | 3相、380V/415V/460V、50Hz/60Hz(地域基準によりカスタマイズ可能)。 |

| 制御システム | Advanced Fully Automatic PLC Control with HMI (Human Machine Interface), real-time online conductivity/TDS meter, pressure gauges, flow meters, auto-flush, low/high pressure protection, VFDs (Variable Frequency Drives) for pumps, and comprehensive fault alarms. |

| 建設資材 |

|

| 入水条件 |

|

| 寸法(概算) | Large industrial footprint; varies significantly based on customization and capacity (e.g., L 5000mm x W 2000mm x H 2500mm for 30m³/hr). |

| 動作温度 | 5°C - 45°C。 |

| カスタマイズ | ODM(Original Design Manufacturer:相手先ブランドによる設計製造)機能により、オーダーメイドのソリューションを提供します。 |

適用業種

- Municipal Drinking Water Supply: Provides vast volumes of safe, potable drinking water for large towns, cities, or regional communities, especially in areas with severe freshwater scarcity or high raw water salinity.

- Coastal Cities & Major Industrial Zones: Essential for **sea water purification** (desalination), transforming abundant ocean water into reliable sources of fresh drinking water, industrial process water, and utility water, ensuring water security.

- Large Food & Beverage Factories: Used as the primary purification stage for high-volume process water in beverage giants (e.g., large-scale bottled water, soft drinks, breweries), dairy processing plants, and major food ingredient production, ensuring uncompromising product purity, consistency, and safety.

- Pharmaceutical & Biotechnology Giants: Provides the initial high-purity water for pre-treatment stages to produce Purified Water (PW), Water for Injection (WFI), and Highly Purified Water (HPW) for drug manufacturing, R&D laboratories, and large-scale medical device reprocessing, adhering to the strictest GMP standards.

- Electronics & Semiconductor Manufacturing (Large Scale): Produces immense volumes of high-purity water for pre-treatment to generate ultra-pure water (UPW) used in advanced chip fabrication, component rinsing, and cleanroom operations, where minute impurities cause critical defects.

- Power Generation (Thermal & Nuclear Plants): Critical for boiler feed water pre-treatment, cooling tower make-up water, and turbine washing in large power plants, preventing scale, corrosion, and optimizing energy efficiency of expensive, high-pressure equipment.

- Chemical Industry (Core Chemical Water Treatment Plant): Serves as a fundamental component in large-scale **chemical water treatment plants**, supplying vast quantities of purified water for complex chemical formulations, dilutions, and various process applications, ensuring product purity, yield, and preventing unwanted reactions.

- 鉱業・金属産業 For large-volume process water, mineral extraction, and specialized wastewater treatment within mining operations, often treating challenging raw water sources.

- Wastewater Treatment & Reuse (Advanced Systems): Employed in multi-stage advanced wastewater treatment facilities to produce high-quality effluent suitable for industrial reuse, agricultural irrigation, or even municipal supply (indirect potable reuse).

- Agriculture (Large-Scale & Specialized): For treating brackish or non-traditional water sources for extensive agricultural irrigation, especially for high-value crops or in water-scarce regions, ensuring optimal plant health and preventing soil salinization.

アドバンテージ・ワン

アドバンテージ2

関連商品

関連商品

よくあるご質問

Q1: 逆浸透システムの寿命はどのくらいですか?

逆浸透膜システムの寿命は、水質とメンテナンスに左右されます。通常、膜は2~3年、システム自体は適切な手入れをすれば10年以上持ちます。

Q2: 異なる水質条件に応じてシステムをカスタマイズできますか?

はい、当社のシステムはすべてフルカスタマイズが可能です。お客様のウォーターレポートとアプリケーションのニーズを分析し、オーダーメイドのソリューションを提供します。

Q3: STARKの機器はどのような規格に準拠していますか?

当社の製品はCE、ISO 9001に準拠しており、ご要望に応じて特定の地域の規制や業界標準に適合するように設計することができます。

Q4: STARK ROシステムの納期はどのくらいですか。

標準システムは7~15日以内に出荷される。カスタマイズされた注文の場合、リードタイムは複雑さによって20~25日に延びることがあります。

Q5: 技術サポートや設置指導は行っていますか?

はい。完全な技術文書、ビデオによる遠隔指導を提供し、ご要望に応じてエンジニアを海外に派遣することも可能です。

Q6: 見積もりには何が含まれていますか?

お見積もりには、ROシステム一式、コントロールパネル、ポンプ、前処理ユニット、必要な付属品が含まれます。ご要望に応じて、設置用工具やスペアパーツも含まれます。