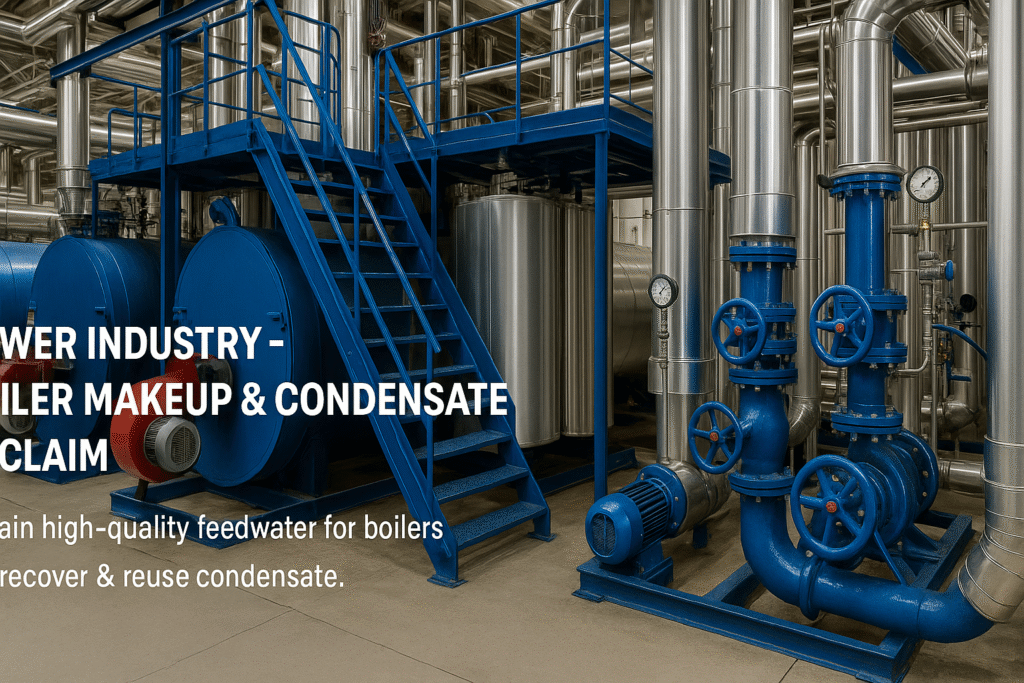

Solution: Energy Sector – Boiler Feedwater and Condensate Recovery Treatment

In power plants and industrial boilers, high-quality feedwater and efficient condensate recovery are critical for minimizing scale formation, corrosion, and energy losses. STARK Water offers integrated treatment solutions—combining filtration, softening, degassing, and condensate polishing—to ensure stable boiler performance, reduced blowdown, and optimized water-energy efficiency.

Key Challenges in Boiler Feedwater & Condensate Treatment

- Strict control of hardness, silica, dissolved solids, and dissolved oxygen

- Scale formation and corrosion risks in boiler tubes and steam lines

- High energy losses from poor condensate recovery

- Variable quality of makeup water sources

- Regulatory requirements for blowdown and wastewater discharge

Our Solution Approach

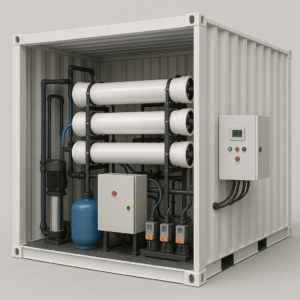

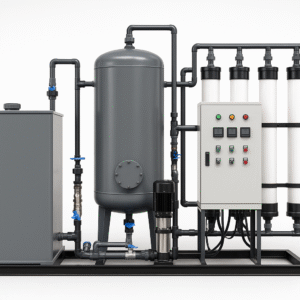

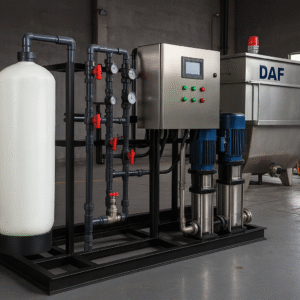

We deliver turn-key treatment trains combining multimedia filtration, softening, deaeration, reverse osmosis (RO), electrodeionization (EDI), and chemical dosing. For condensate recovery, we integrate flash vessels, vacuum deaerators, and polishing filters to capture and reuse up to 90% of condensate, cutting makeup water and fuel costs.

Typical Process Flow:

1. Multimedia filtration & activated carbon

2. Water softening (ion exchange)

3. Deaeration (thermal or vacuum)

4. Reverse osmosis / EDI for high-purity feedwater

5. Chemical dosing and corrosion inhibitors

6. Condensate flash recovery & polishing

7. Blowdown treatment and reuse

Typical Application Scenarios

High-Quality Makeup Water Treatment

Ensures consistent removal of hardness, silica, and dissolved gases to protect boiler tubes and prolong equipment life.

Thermal & Vacuum Deaeration

Efficiently strips dissolved oxygen and CO₂ from feedwater, minimizing corrosion in boiler and steam lines.

RO & EDI Polishing for Ultra-Pure Water

Delivers sub-ppb conductivity for high-pressure boilers and critical steam applications.

Condensate Recovery & Reuse

Captures and recycles up to 90% of condensate, reducing makeup water needs and cutting fuel costs.