Solution: Food & Beverage Factories – CIP Cleaning and Production Water Treatment

In the food and beverage industry, high water quality and stringent hygiene standards are essential for safe production. Reliable process water treatment and effective CIP (Clean-in-Place) cleaning systems protect product safety, optimize operation costs, and ensure compliance with global regulations. STARK Water delivers customized solutions for both CIP cleaning and process water supply, helping you guarantee quality at every stage of manufacturing.

Key Challenges in Food & Beverage Water Treatment

- Strict hygiene and microbial control requirements

- Efficient removal of organic and inorganic impurities

- High-frequency cleaning cycles for pipes and equipment

- Process water reuse and resource optimization

- Compliance with food safety and environmental standards

Typical Application Scenarios

Automated CIP Cleaning for Production Lines

Delivers fast, thorough cleaning of tanks, pipes, and bottling lines with minimal downtime and reduced chemical use.

High-Purity Process Water Supply

Ensures safe and stable process water for mixing, dilution, ingredient preparation, and direct product contact.

Wastewater Recycling & Resource Optimization

Reduces total water consumption and treatment costs by reclaiming and reusing rinse water and cleaning solutions.

Final Rinse & Product Contact Water Safety

Provides ultra-pure final rinse water for bottles and containers—prevents contamination and ensures every product meets quality standards.

Our Solution Approach

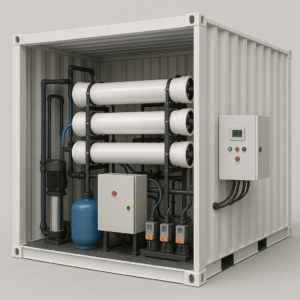

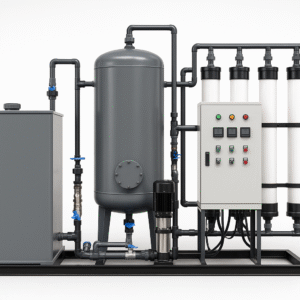

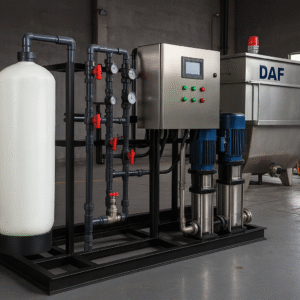

We provide complete process water and CIP system integration using technologies like ultrafiltration, reverse osmosis, and smart dosing systems. Our solutions minimize contamination risk, reduce cleaning time, and lower water/chemical consumption. Systems are tailored to each plant’s specific production process and cleaning requirements.

Typical Process Flow:

1. Pre-filtration (sand & carbon filters)

2. Ultrafiltration (UF) for bacteria and particles

3. Reverse osmosis (RO) for pure process water

4. Automated CIP unit with precision chemical dosing

5. Wastewater recycling & discharge treatment