Solution: Textile & Paper Industry – Process Water and Wastewater Pretreatment

In textile and paper manufacturing, water quality directly impacts fiber strength, color consistency, and machine longevity. Efficient pretreatment of both process water and wastewater protects equipment, reduces chemical consumption, and helps meet stringent discharge regulations. STARK Water offers tailored pretreatment trains to optimize water use, recover valuable chemicals, and ensure environmental compliance.

Key Challenges in Textile & Paper Water Treatment

- High loads of suspended solids, dyes, and organic matter

- Scaling and fouling in heat exchangers and membranes

- Variable pH and chemical oxygen demand (COD)

- Strict effluent discharge limits (BOD, COD, TSS)

- Need for chemical recovery (e.g., alkali, dyes)

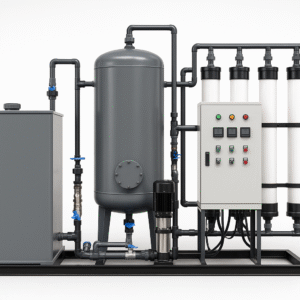

Our Solution Approach

We design multi-stage pretreatment systems combining screening, coagulation/flocculation, multimedia filtration, ultrafiltration (UF), and advanced oxidation processes (AOP). For wastewater, we integrate DAF (dissolved air flotation), biological treatment, and polishing filters to meet reuse or discharge standards.

Typical Process Flow:

1. Coarse screening & grit removal

2. Coagulation & flocculation

3. Dissolved air flotation (DAF)

4. Multimedia filtration & activated carbon

5. Ultrafiltration (UF) for fine solids removal

6. Advanced oxidation (e.g., UV/H₂O₂) for color and COD

7. Polishing filtration for reuse or discharge

Typical Application Scenarios

Coarse Screening & Grit Removal

Protects downstream equipment by removing large fibers, lint, and sand particles at the primary stage.

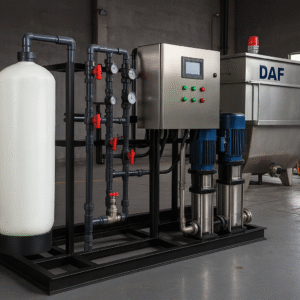

Dissolved Air Flotation (DAF)

Efficiently separates suspended solids, oils, and surfactants for high solids load wastewater.

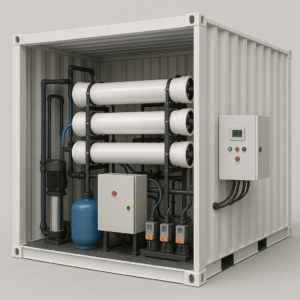

Ultrafiltration (UF) Polishing

Removes fine colloids and residual dyes, delivering clear water for reuse in process or rinse applications.

Advanced Oxidation for Color & COD

Utilizes UV/H₂O₂ or ozone to break down refractory organics, ensuring compliance with discharge limits.