Quick, audit-ready fundamentals for project engineers.

This 10-minute guide explains what a stainless steel purified water tank is, where it fits in your process train, and how to choose materials, size the working volume, design hygienic nozzles, and verify CIP/SIP. Use it to scope B2B projects faster, keep validation teams happy, and shorten RFQ cycles.

Related playbooks: reverse osmosis water treatment system, EDI vs mixed bed polishing, CIP/SIP stainless steel filter housings, and our ステンレス製品.

1) Where a stainless steel purified water tank fits in the process

Most industrial purified water systems follow: Pretreatment → RO (single or double pass) and/or EDI → stainless steel purified water tank → distribution loop with a sanitary pump, UV/TOC monitor, and return line. The tank decouples production from demand, prevents pump short-cycling, and stabilizes temperature and carbon dioxide (CO2) before water reaches points of use.

- Upstream: RO/EDI produces permeate/polished water at steady flow.

- Tank: provides surge, mixing, degassing, instrumentation and a hygienic hold-up volume.

- Downstream: loop recirculates at 1–1.5 m/s (typ.), keeping biofilm risk low and ensuring fast response at taps.

2) Materials & hygiene: 316L vs 304, finishes, gaskets

Choose 316L when chloride or low TOC risk matters; choose 304 when budgets are tight and chemistry is benign. Inside the stainless steel purified water tank, specify a smooth finish (e.g., Ra ≤ 0.4–0.8 µm, per industry/validation needs).

- 316L vs 304: 316L (Mo) offers better pitting resistance; 304 is cost-effective.

- Surface finish: mechanical polish plus passivation or electropolish; verify Ra on certificates.

- Seals: EPDM, PTFE or FKM depending on CIP chemistry and temperature windows.

- Hygienic details: self-draining heads, crevice-free welds, tri-clamps, short dead-legs (<2D/3D where applicable).

3) Sizing the tank: working volume, surge, NPSH & turnover

Start from the peak draw profile and add buffer (surge + CIP/cleaning allowance). The stainless steel purified water tank must provide enough NPSH to the distribution pump and guarantee minimum turnover (e.g., 24 h or as required).

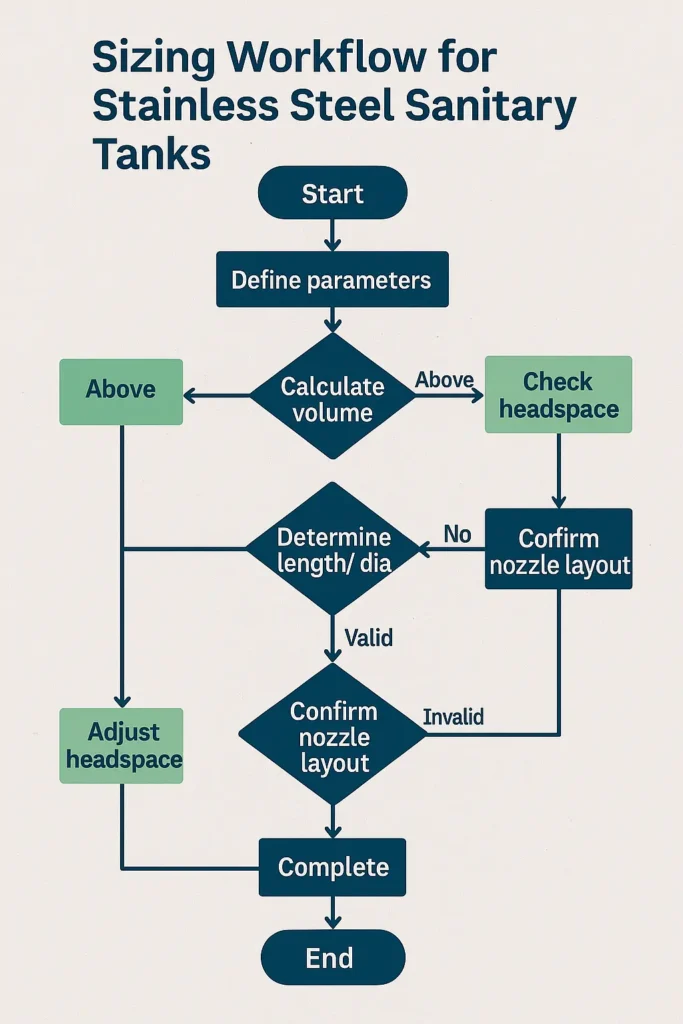

Rule-of-thumb workflow

- Working volume ≈ Peak demand (m³/h) × required buffer time (h) + cleaning/maintenance allowance.

- Turnover ≥ operations requirement (e.g., once per day), else reduce volume or raise loop flow.

- NPSH & headspace: maintain flooded suction; avoid vacuum collapse during rapid draws.

Example A — Beverage plant

Peak 8 m³/h for 20 min bursts plus base 2 m³/h. Buffer 30 min. Working volume ≥ 8×0.33 + margin ≈ 2.6–3.0 m³.

Example B — Electronics UPW loop

Steady 3 m³/h + occasional 5 m³/h CIP feed. Minimum turnover once per 24 h. Tank 2.5–3.5 m³ supports both cases.

4) Nozzle & internals: inlet, outlet, spray ball, vent, drain, level

Hygienic nozzle layout is critical. A validated spray device (fixed spray ball or rotary) must reach all wetted surfaces. The vent must include a sterilizing grade hydrophobic filter (commonly 0.2 µm) with heat jacket if condensation is likely.

- Inlet/outlet/recirculation: position to encourage sweeping flow and mixing; avoid dead zones.

- Drain: full-drain bottom with steep cone/dished head; prove no liquid hold-up.

- Instrumentation: level, temp, conductivity/TOC, pressure/vacuum relief; hygienic sight glass optional.

- Spray device: coverage test or riboflavin tests for high-risk applications.

5) Headspace & contamination control

The headspace above purified water is where condensate and aerosols can seed problems. For a stainless steel purified water tank, use a heated vent filter or inert gas overlay when temperature swings are large.

- Vent filter: 0.2 µm PTFE/PVDF cartridge with integrity testing and scheduled changeout.

- Condensation control: insulation, heat tracing, or gentle headspace heating to prevent “rain-in-tank”.

- Thermal regimes: ambient loops may add periodic pasteurization; hot loops rely on continuous 65–80 °C.

6) Controls, alarms & documentation

Keep controls simple, visible, and well-logged. Typical interlocks: low level → pump stop; over-pressure → relief; high temp/TOC/conductivity → alarm and divert to drain. Good documentation shortens audits.

- Trending: level, temperature, TOC, conductivity, ΔP across vent filter, loop flow & return temperature.

- Records: receiving inspection, surface finish certificates, pressure tests, passivation/electropolish reports.

- Validation (as applicable): IQ/OQ/PQ pack, cleaning coverage, and vent filter integrity traces.

7) Installation & O&M quick notes

- Anchor & isolate vibration; protect polishing on site; verify no weld discoloration after tie-ins.

- Minimize dead-legs; keep all branches short and self-draining toward the stainless steel purified water tank.

- Service schedule: spray device inspection, vent filter integrity, passivation check, gasket rotation, sight-glass O-rings.

8) Purchasing checklist (BOM) & RFQ template

Copy/paste this into your next RFQ and attach your P&ID:

- Tank body: volume (working/total); 316L or 304; head type (cone/dished); self-draining design.

- Finish: inside Ra target (e.g., ≤0.6 µm), passivation/electropolish, weld maps and certificates.

- Nozzles: inlet/outlet/recirculation, drain, spray ball, vent with 0.2 µm filter, temp/level/TOC ports.

- Accessories: insulation & cladding, heat tracing, manway type, ladder/handrails if vertical.

- Testing: hydro/pressure tests, surface finish verification, documentation pack.

- Delivery & scope: skids/pumps/loop options; FAT/SAT; start-up and training.

Looking for a quotation or a matching distribution loop? Visit our ステンレス製品 または 見積依頼.

9) FAQs

Do I need 316L or is 304 acceptable for RO permeate?

For most neutral RO permeate, 304 can work; choose 316L if you have elevated chlorides, aggressive CIP chemistry, or stringent validation/UPW expectations.

What inside finish is typical?

Food & beverage often target Ra ≤0.8 µm; pharma/electronics push Ra ≤0.6 or ≤0.4 µm with passivation/electropolish.

How do I size the vent filter?

Calculate worst-case air in/out during fast fill and rapid draw; add safety margin; verify thermal rating and integrity testing method.

Can one tank feed both RO and EDI loops?

Yes, with careful hydraulics and valve logic; avoid cross-contamination and maintain turnover in each loop.

Vertical or horizontal orientation?

Vertical saves footprint and drains well; horizontal fits low headroom and can improve mixing in some layouts.

Summary

A successful stainless steel purified water tank project balances hygienic construction (materials/finish/drainability), water-hydraulics (volume, turnover, NPSH), and verifiable CIP/SIP. Nail these three, and commissioning becomes routine.

Related resources

- RO membrane housing diagram

- RO commissioning checklist

- Chlorine CT & dosage calculator

- CIP/SIP for stainless housings