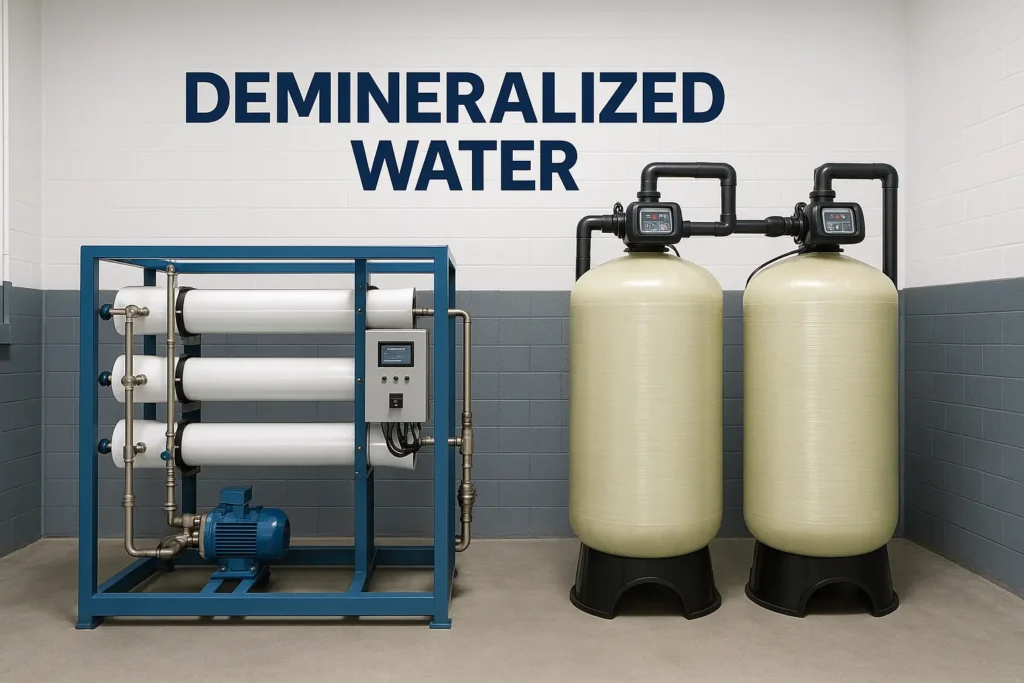

A water deionization system removes dissolved ions to produce high-purity water for industry and labs. Depending on flow, chemistry and chemical-handling policy, you can choose mixed-bed DI, RO/EDI (electrodeionization), or service DI (exchange tanks). This guide clarifies the options, shows how to size and accept a system, and links to three ready configurations you can request a quote on. If you already have specs, go straight to our EDI systems.

What Is a Water Deionization System?

Deionization removes cations and anions to reach target conductivity/resistivity. Common targets range from 1–18.2 MΩ·cm depending on process (boiler, plating, cleaning, lab Type I/II/III). Three practical routes exist: mixed-bed DI (ion-exchange), RO + EDI (no acid/caustic regeneration), and service DI (exchange tanks).

DI vs RO/EDI vs Service DI — Quick Comparison

| Option | Best for | Typical Quality | OPEX & Maintenance | Pros | Watch-outs |

|---|---|---|---|---|---|

| Mixed-bed DI | Intermittent use, ultra-high resistivity polishing | Up to 18.2 MΩ·cm | Resin replace/regen (acid/caustic) or outsourced | Peak purity, fast startup | Chemicals/logistics; needs good pretreatment |

| RO + EDI | Continuous production ≥0.5 m³/h | ~5–15 MΩ·cm (higher with polishing) | Power + cartridges + dosing; no acid/caustic | Stable, automated, operator-friendly | Requires RO; control hardness/CO₂/silica |

| Service DI (exchange tanks) | Temporary or small points of use | Medium–high (model dependent) | Per-tank service fee | No onsite regeneration | Unit water cost higher at scale |

Match Your Need to Our 3 Ready Configurations

Choose the closest configuration and we’ll tune recovery and stack count to your water analysis. All options are engineered as a water deionization system with RO pretreatment.

| Config | Typical Flow | Target Resistivity | Great For | Link |

|---|---|---|---|---|

| Compact RODI Skid | 200 LPH (≈0.2 m³/h) | 5–10 MΩ·cm | Labs, pilot skids, plating tools | 200 LPH Water Deionization System (RO+EDI) |

| Module-based RODI | ~1–3 m³/h | 5–15 MΩ·cm | Electroplating, precision cleaning, boiler make-up | Water Deionization System — RO+EDI Module |

| High-capacity Rack | ~5–20 m³/h (modular stacks) | 8–15 MΩ·cm | Industrial parks, central utilities, reuse polishing | High-Capacity Water Deionization System (RO+EDI) |

Not sure which fits? Compare our EDI-based water deionization systems →

Quality Targets & Monitoring

- Resistivity/Conductivity: setpoint at 25 °C; alarms and auto-divert recommended.

- TOC/Bacteria (if regulated): UV/UF or final filters as required.

- Trending: stage ΔP, temperature compensation, event/alarm logs.

Use Cases & ROI

For continuous processes, a water deionization system built on RO/EDI often lowers total cost versus service DI once flow exceeds ~0.5–1 m³/h. You eliminate acid/caustic regeneration, automate quality control (temperature-compensated resistivity), and reduce operator time. Typical wins include plating and surface finishing lines, boiler make-up, precision cleaning, lab distribution loops and electronics pretreatment. When ultra-high resistivity is required at point of use, a small mixed-bed polisher can be added downstream without changing the main skid.

Sizing a Water Deionization System

デザイン・インプット

- Feed: conductivity (µS/cm), hardness (as CaCO₃), silica, alkalinity/CO₂, temperature.

- Demand: average & peak flow (m³/h), hours/day, continuous vs batch.

- Targets: required resistivity (MΩ·cm @25 °C), TOC/bio limits if any.

- Constraints: no-acid policy, footprint, power, noise.

Typical Train

- 50→5 µm filtration; antiscalant and pH/alkalinity management.

- Reverse osmosis (single or double pass depending on feed/targets).

- EDI for continuous deionization; optional polishing (UV/UF/MB).

Acceptance & Documentation (FAT/SAT)

- Permeate resistivity at temperature, flows and recovery recorded; ΔP by stage logged.

- Interlocks verified: low feed, high conductivity, auto-flush/lay-up, permissives/trips.

- Handover: GA, P&ID, IOM, spares, commissioning logs, water-test sheets.

よくあるご質問

- Is RO/EDI the same as a water deionization system?

- RO/EDI is one common way to build a water deionization system. Alternatives include mixed-bed DI and service DI tanks.

- Can a water deionization system reach 18.2 MΩ·cm?

- Yes—with proper pretreatment and polishing. Many industrial targets are 5–15 MΩ·cm.

- Which option is best for intermittent use?

- Mixed-bed DI or service DI is often more economical and simpler for small, intermittent points of use.

- What feed limits matter most?

- Hardness, alkalinity/CO₂ and silica; these determine recovery and cleaning frequency.

- What should be monitored continuously?

- Conductivity/resistivity at 25 °C, temperature, ΔP by stage, and events/alarms.

Can I add polishing to reach ultra-high resistivity later?

Yes. Start with RO/EDI for stable base quality, then add a small mixed-bed or cartridge polisher at the point of use to reach ultra-high resistivity when needed.