This guide explains what a double pass reverse osmosis system (two-pass RO) is, why engineers choose it over single-pass RO, and how to design, operate and verify performance. We cover system architecture, interstage piping options, recovery calculations, water chemistry (boron/silica/CO2), controls, reliability and FAQs—so you can scope projects faster and avoid common pitfalls.

Executive snapshot: when to choose a double pass reverse osmosis system

- Use cases: UPW & electronics, battery plants, pharma WFI pretreatment, beverage blending water, high-pressure boiler makeup.

- Why two-pass? Lower conductivity/TOC, better boron/silica control, lower CO2, robust polishing without MB/EDI (or as a stable feed to EDI).

- Compared with single-pass + polishing: two-pass RO reduces oxidant risk to downstream polishing, simplifies chemical footprint, and can achieve <5–10 µS/cm consistently with proper interstage conditioning.

| 매개변수 | Single-pass RO | Double pass RO | 참고 |

|---|---|---|---|

| Typical overall recovery | 70–80% | 85–95% | Depends on R1, R2, and any brine recirculation strategy. |

| Permeate conductivity | 15–40 µS/cm | 3–10 µS/cm | With interstage pH/degassing when CO2 is high. |

| Boron/silica control | 보통 | 높음 | Interstage pH raise improves weak-acid rejection. |

| Complexity | Low | Medium | Two high-pressure sections & interlocks. |

How a Double Pass Reverse Osmosis System Works

RO-1 reduces salinity and particulates; the interstage adjusts chemistry and hydraulics (pH, degassing, temperature, pressure); RO-2 then polishes to final quality. Overall recovery follows mass balance:

Overall recovery: R합계 = 1 − (1 − R1) × (1 − R2)

Example: if R1=0.75 and R2=0.80, then R합계 ≈ 1 − (0.25 × 0.20) = 95%.

Because RO-2 sees cleaner feed, high-flux elements are often selected in the second pass. The second pass is less sensitive to nominal salt rejection, but its TMP and ΔP must remain within OEM limits.

Double Pass Reverse Osmosis System Components (BOM)

Automation: interlocks, trends, alarms, remote access and event logs.

전처리: raw-water pump, dosing (disinfection/coagulation/antiscalant/SBS), multimedia filter, GAC (if oxidants present), cartridge guard filter.

RO-1: HP pump, pressure vessels & elements, gauges and transmitters (P/ΔP/F/Cond/ORP/Cl2/pH/temp).

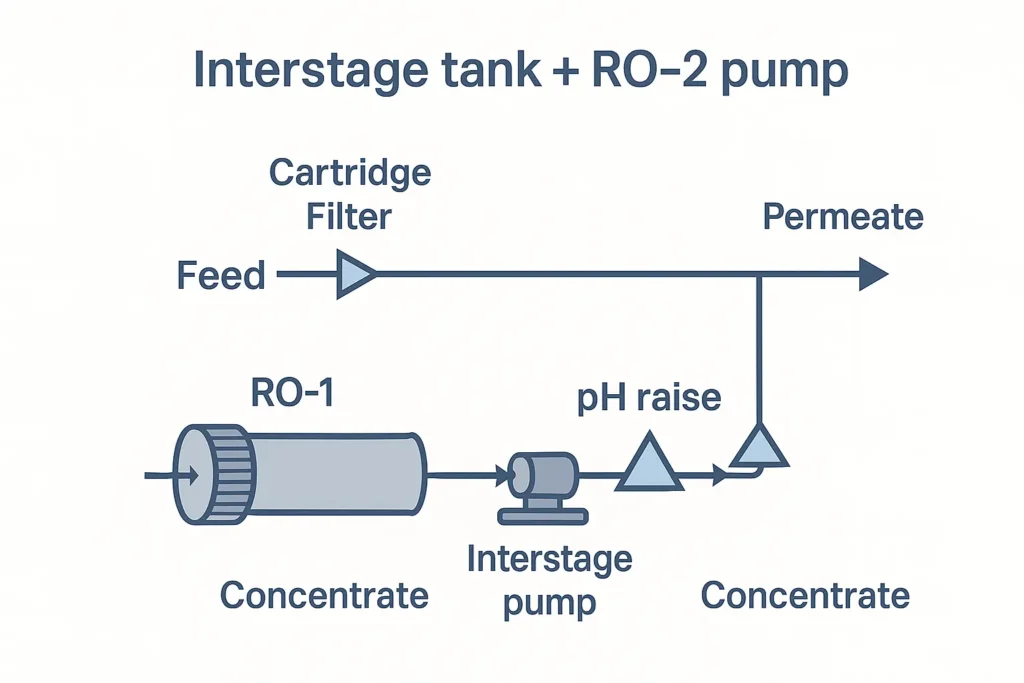

Interstage: optional tank, interstage HP pump, static mixer, degasser/decarbonator if CO2 is high, NaOH dosing for pH raise to improve boron/silica removal.

RO-2: high-flux elements, recovery/back-pressure control, permeate and concentrate loops.

CIP & flushing: acid/caustic/oxidant within membrane limits; isolation, soak and final neutral rinse.

Post-treatment (optional): EDI, UV-TOC, polishing MB, SS316L storage & distribution.

Double Pass Reverse Osmosis System Design Features

- Membrane choice: High-flux for RO-2; verify element limits, temperature, ΔP and biofouling risk.

- Interstage pH strategy: Raise pH (e.g., 9–10) to increase rejection of weak acids (boron, silica). Balance against scaling indices and adjust antiscalant accordingly.

- Degassing/Decarbonation: When alkalinity/CO2 is high, remove CO2 in the interstage to reduce permeate conductivity and EDI load.

- Dechlorination: Protect PA membranes with GAC or SBS; verify free Cl2=ND at RO-1 inlet.

- Concentrate recirculation: Returning RO-2 concentrate to RO-1 suction can raise overall recovery—check NPSH margin, mixing, and temperature rise.

- 재료 및 위생: For food/pharma/UPW, use SS316L, sanitary welding and hygienic valves; design for smooth flushing and drainability.

- Energy: Two HP sections increase wire-to-water energy, but improved overall recovery and fewer polishing steps can offset OPEX.

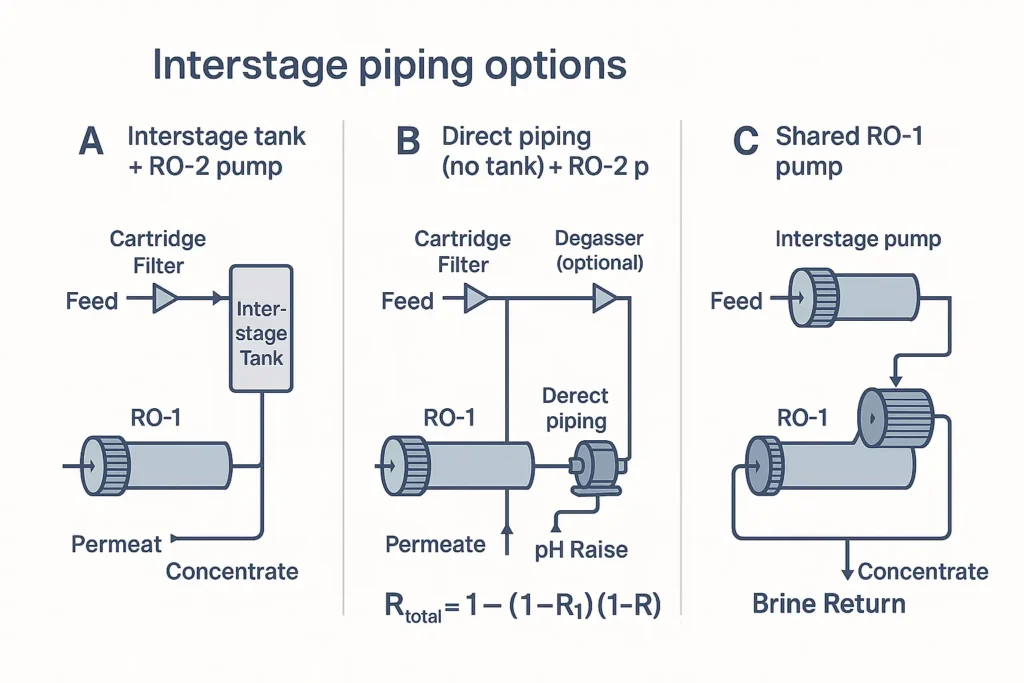

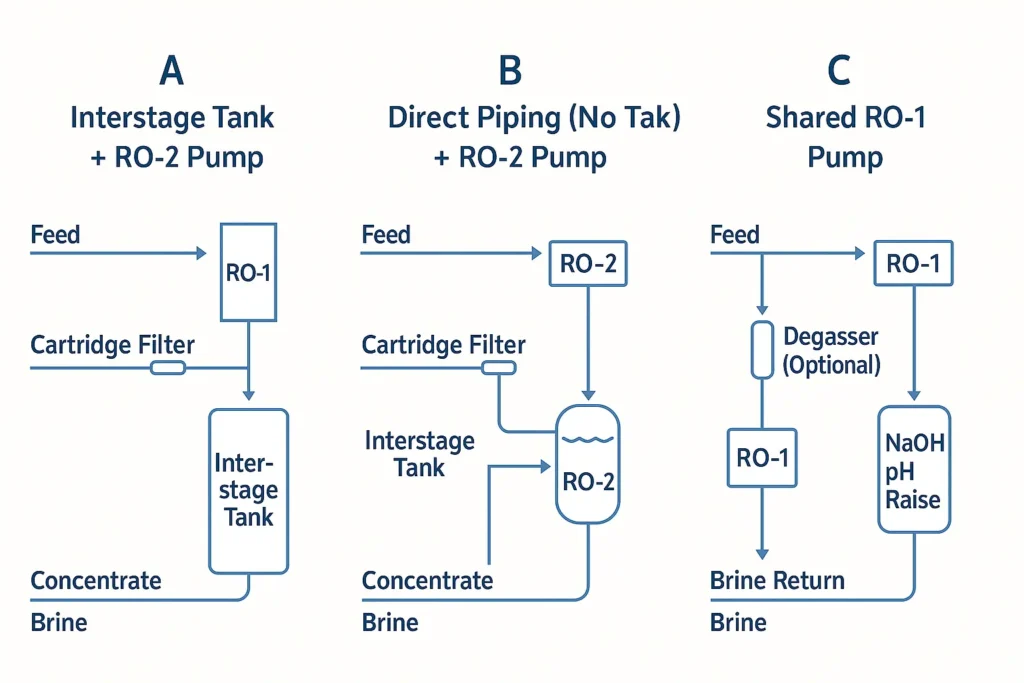

Interstage Options for a Double Pass Reverse Osmosis System

| Option | Pros | Cons | Typical scale |

|---|---|---|---|

| Interstage tank + RO-2 HP pump | Best buffer; simple control; easy online cleaning & startup sequences | More footprint/CAPEX; sanitation needed for hygienic service | Medium to large systems; variable feeds |

| Direct piping (no tank) + RO-2 HP pump | Compact; fewer vessels; faster project timelines | Tighter interlocks/flow balance; less surge capacity | Small to mid systems; stable pretreatment |

| Shared RO-1 HP pump (no tank, no RO-2 pump) | Lowest CAPEX; smallest footprint | Strict pressure gradient control; risk of backpressure and upsets | Small systems with steady load |

Double Pass Reverse Osmosis System Sizing Toolbox

6.1 Mass balance & recovery

Given feed flow F, choose R1 and R2 to meet quality and energy goals. Overall recovery is computed as shown earlier; concentrate and permeate flows follow directly.

Example A: F = 20 m³/h, R1=75%, R2=80% → P합계 ≈ 19 m³/h; C합계 ≈ 1 m³/h.

Example B (with RO-2 brine return): set recycle ratio so RO-1 suction NPSH ≥ required + safety; re-check temperature rise and antiscalant window.

6.2 Pumping & hydraulics

- Size RO-1 and RO-2 HP pumps for design flux and ΔP, plus margin for fouling and temperature swings.

- For brine return to RO-1 suction, validate NPSH available > NPSH required + 1–2 m and provide a mixing tee/static mixer.

6.3 Element staging

Use clean-in/clean-out design; stage elements by flux and ΔP. RO-2 can often use fewer pressure vessels at higher flux; keep each stage within OEM ΔP limits and provide concentrate throttling/back-pressure valves.

Water Chemistry in a Double Pass Reverse Osmosis System

- Boron & silica: interstage pH raise (to 9–10) improves rejection; confirm stability with antiscalant vendor limits.

- CO2 & conductivity: interstage degassing lowers permeate conductivity and reduces EDI load.

- Scaling risk: Even with lower TDS after RO-1, check LSI/CSI, CaSO4, Ba/Sr sulfates, and iron/manganese; set CIP triggers.

- Analytics: continuous monitoring of permeate and concentrate conductivity, ΔP, pH, ORP/Cl2, temperature and flows; trend vs. acceptance baseline.

This double pass reverse osmosis system article focuses on decisions engineers make under real plant constraints.

Operating a Double Pass Reverse Osmosis System

- Start/stop: prevent backpressure from RO-2 to RO-1; sequence HP pumps and interstage valves; provide slow-ramp VFD logic.

- Flush & sanitation: low-TDS permeate flush on shutdown; periodic hot WFI-grade or chemical sanitization for hygienic service.

- CIP triggers: flux decline, ΔP rise, conductivity drift; select acid/caustic/oxidant within limits and rinse to neutral.

- Common issues: interstage air lock, brine return valve mis-set, carbon fines, analyzer drift—control by interlocks and routine calibration.

Further reading: US EPA – Water Research; Water Environment Federation – Publications. Related pages on our site: RO system overview, UF membrane guide, HP pumps & dosing accessories.

Typical specifications & performance ranges

| Industry | Feed TDS | R1/R2 | Overall R | Permeate target | 참고 |

|---|---|---|---|---|---|

| Electronics/UPW | 200–1,000 mg/L | 75–80% / 80–85% | 92–95% | <5 µS/cm, boron <0.2 mg/L | Interstage degas & pH raise common |

| Pharma (PW/HPW) | 100–800 mg/L | 70–80% / 80–85% | 90–94% | <10 µS/cm, TOC control | Sanitary 316L, hygienic valves, hot water/chem sanitation |

| Beverage | 200–1,500 mg/L | 70–80% / 80–85% | 90–94% | Stable taste profile | Consistent CO2 management |

| Boiler makeup | 100–1,000 mg/L | 75–80% / 80–85% | 92–95% | <10 µS/cm | Optional EDI polish |

Next steps: get a two-pass RO design pack

Upload feed analysis, target conductivity/boron/silica, desired recovery, footprint/energy constraints, and we’ll return a preliminary PFD + set points + BOM within 24 hours. Request a review →

Related pages: RO system overview, UF membrane guide, HP pumps & dosing accessories, stainless-steel tanks & manifolds.

자주 묻는 질문

Double pass RO vs single pass + EDI: how to choose?

Two-pass RO simplifies oxidant control and can meet many specs alone; EDI adds robustness for ultra-low conductivity and continuous polishing. Choose by quality target, energy, and validation requirements.

Do I need an interstage tank?

Where feed or RO-1 permeate is unstable or cleaning is frequent, a tank improves buffering and startup/shutdown control. Compact systems with steady flow can go tank-less.

Why use high-flux elements at RO-2?

RO-2 sees cleaner water, so you can run higher flux at similar ΔP; overall salt passage is dominated by RO-1 and interstage conditioning.

Can I return RO-2 brine to RO-1 suction?

Yes, to raise overall recovery—verify NPSH margin, thorough mixing, temperature rise and antiscalant limits; add alarms for abnormal suction pressure.

How do I manage boron and silica across two passes?

Raise interstage pH and consider degassing; keep scaling indices within limits and verify boron/silica at both passes during site acceptance.

Stark Water Engineering Team — process design, commissioning & troubleshooting

마지막으로 검토되었습니다: 2025-10-13