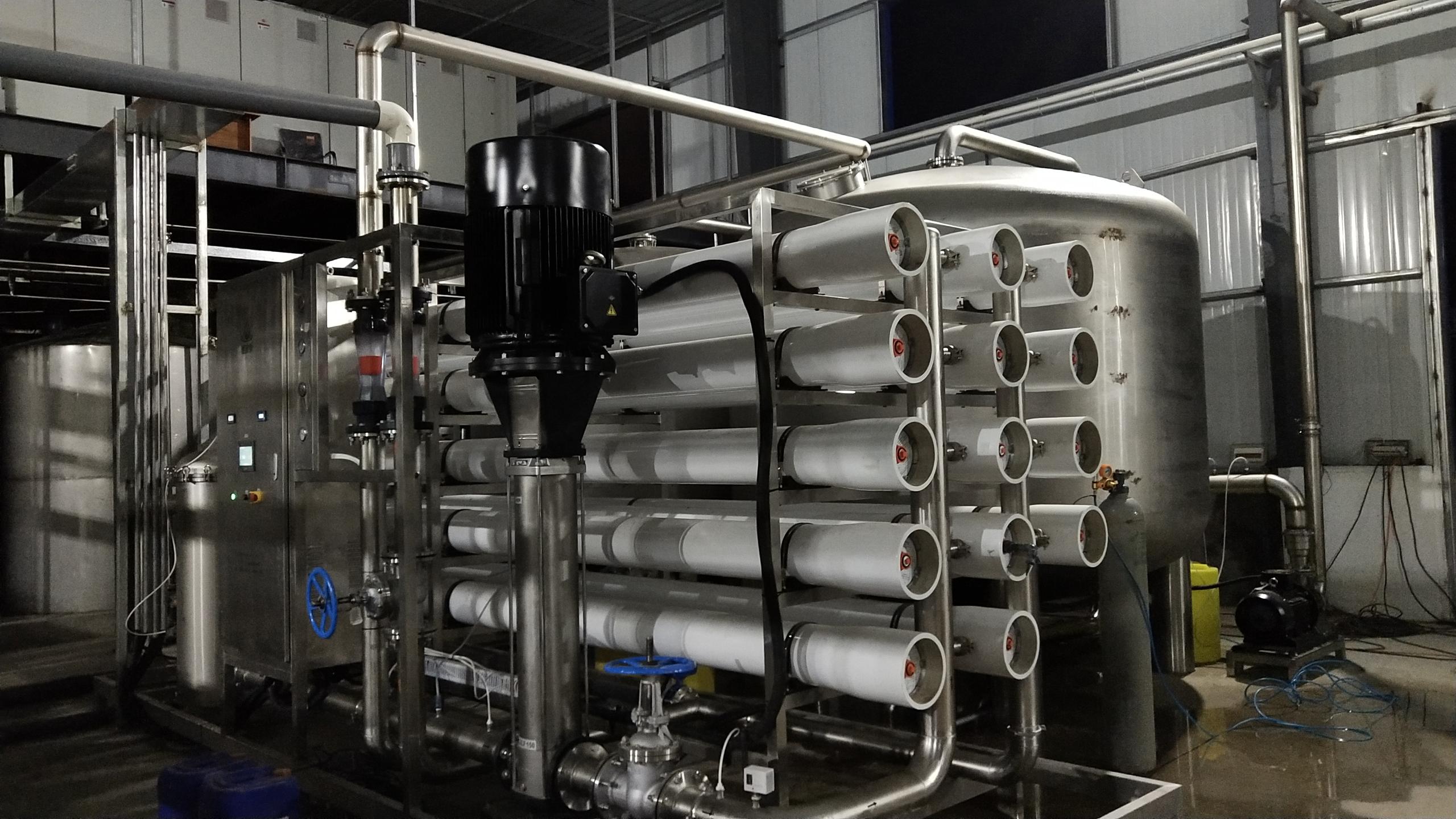

30T 대형 산업용 역삼투압 장비 물 담수화 정화

30T 대형 산업용 역삼투압 장비 물 담수화 정화30T 대형 산업용 역삼투압 장비 물 담수화 정화

Secure a vast supply of high-purity water with Stark Water’s 30T Large Industrial Reverse Osmosis Equipment. This large industrial reverse osmosis equipment is specifically engineered for robust water desalination purification, delivering 30,000 liters per hour of clean water for critical industrial processes and large-scale applications.

제품 설명

In the expansive and demanding world of heavy industry, manufacturing, and large-scale utilities, the need for immense volumes of consistently purified water is paramount. Contaminated or unsuitable water can lead to catastrophic equipment failure, compromised product quality, and severe operational inefficiencies. The Stark Water 30T Large Industrial Reverse Osmosis Equipment is meticulously engineered to address these challenges head-on, providing a high-capacity, robust, and reliable solution for comprehensive water desalination purification.

30T Large Industrial Reverse Osmosis Equipment: Engineered for Scale

The “30T” in its designation signifies a formidable capacity of 30 tons per hour (30,000 liters per hour or 30 m³/hr), positioning this equipment as a cornerstone for very large-scale industrial operations. This large industrial reverse osmosis equipment is built from the ground up for continuous, heavy-duty performance, capable of meeting the enormous water demands of major factories, power plants, and vast municipal systems. Its robust design, utilizing high-grade materials and industrial-strength components, ensures exceptional durability and longevity, even under the most challenging operating conditions. This scale allows for efficient throughput, minimizing downtime and maximizing productivity across extensive industrial processes.

Comprehensive Water Desalination Purification Capabilities

This powerful equipment offers comprehensive water desalination purification, making it incredibly versatile for diverse raw water sources and purity requirements. It leverages advanced Reverse Osmosis (RO) technology, which is highly effective in removing a broad spectrum of contaminants:

- 담수화: Specifically optimized for transforming high-salinity sources, such as seawater or highly brackish groundwater, into fresh, potable water or high-quality process water. This is crucial for industries and communities located in water-scarce coastal regions.

- General Purification: Equally adept at purifying less saline raw waters (e.g., municipal water, well water) by removing dissolved salts, heavy metals, organic compounds, bacteria, and viruses.

- Broad Contaminant Removal: Effectively reduces Total Dissolved Solids (TDS), ensures ultra-low conductivity, and provides a barrier against microbiological contaminants, meeting stringent purity standards for various industrial applications.

The system’s modular design allows for customization and integration of specific pre-treatment and post-treatment stages, ensuring the output water quality precisely matches your operational needs, from general utility to ultra-pure process water.

Reliability, Efficiency, and Long-Term Investment Value

Investing in the Stark Water 30T Large Industrial Reverse Osmosis Equipment translates into significant long-term value and operational confidence. Its automated controls provide real-time monitoring and operational safeguards, simplifying management and ensuring consistent performance. The inherent efficiency of RO technology, combined with our optimized system design, leads to reduced energy consumption and minimal chemical usage compared to traditional purification methods. This robust construction and efficient operation minimize maintenance requirements and downtime, ensuring a continuous supply of high-purity water, thereby extending the lifespan of your critical industrial assets and securing a rapid return on investment.

제품 매개변수

The Stark Water 30T Large Industrial Reverse Osmosis Equipment is engineered for high-capacity, robust, and reliable water desalination purification. Here are its key technical specifications:

| 매개변수 | 사양 / 사용자 지정 옵션 |

|---|---|

| 핵심 키워드 포커스 | large industrial reverse osmosis equipment design and capabilities. |

| 순수한 물 용량 | 30 Tons per Hour (30,000 Liters Per Hour / 30 m³/hr / approx. 132 GPM). Custom capacities available. |

| 원수 공급원 호환성 | 상수도, 우물물, 기수(TDS 최대 15,000ppm) 또는 바닷물(SWRO 구성의 경우 TDS 최대 45,000ppm). |

| RO 멤브레인 유형 | High-rejection Thin-Film Composite (TFC) RO Membranes (e.g., 8040 series). Specifically SWRO membranes for desalination. |

| 고압 펌프 | Heavy-duty, energy-efficient, corrosion-resistant centrifugal or positive displacement pumps, often with Variable Frequency Drives (VFDs) for optimized energy use. |

| 전처리 시스템 |

|

| 염분 제거율 | ≥98.5% - 99.5%(BWRO); ≥99.5% - 99.7%(SWRO). |

| 수분 회수율 | 40% – 75% (BWRO); 30% – 50% (SWRO). Dependent on raw water quality, desired recovery, and system design. |

| 출력 수질 | Meets WHO drinking water standards; customized for specific industrial process water needs (e.g., low TDS for boiler feed, electronics grade UPW feed). |

| 전원 공급 장치 | 3상, 380V/415V/460V, 50Hz/60Hz(지역 표준에 따라 사용자 지정 가능). |

| 제어 시스템 | Advanced Fully Automatic PLC Control with HMI, real-time online monitoring (TDS/conductivity, pressure, flow, temperature), auto-flush, automated CIP (Clean-in-Place) cycles, energy recovery device control (for SWRO), and comprehensive safety interlocks/alarms. Remote monitoring capability. |

| 건축 자재 |

|

| 유입수 요구 사항 |

|

| 치수(대략적인) | Significant industrial footprint; fully customized skid-mounted or modular design (e.g., L 5000mm x W 2000mm x H 2500mm). |

| 작동 온도 | 5°C - 45°C. |

| 인증 | 관련 국제 표준(예: ISO, CE, ASME, 요청 시)을 충족하도록 설계되었습니다. |

해당 산업

The Stark Water 30T Large Industrial Reverse Osmosis Equipment is a transformative solution for vast industrial and municipal water demands, capable of purifying immense quantities of diverse and challenging water sources, including seawater. Its immense capacity and robust design make it indispensable for:

- Municipal Water Utilities: Provides immense volumes of safe, potable drinking water for large towns, cities, or regional communities, especially vital in areas facing severe freshwater scarcity through large-scale desalination projects.

- Major Industrial Parks & Heavy Manufacturing Facilities: Supplies critical high-purity process water for vast industrial complexes including electronics, automotive, chemicals, pharmaceuticals, and metals processing, ensuring product consistency, preventing equipment damage, and meeting stringent quality standards for high-volume production.

- Food & Beverage Production Plants: Essential for producing massive quantities of purified water for global beverage brands (e.g., large-scale bottled water, soft drinks, breweries, dairies), extensive food ingredient processing, and comprehensive cleaning-in-place (CIP) systems, guaranteeing product safety and quality at scale.

- Power Generation & Energy Sector: Critical for boiler feed water purification in large thermal, nuclear, and combined-cycle power plants, massive cooling tower make-up water, and turbine washing, preventing scaling, corrosion, and optimizing energy efficiency of very expensive, high-pressure equipment.

- Pharmaceutical & Biotechnology: Serves as the primary purification unit to generate vast volumes of Purified Water (PW) and pre-treat for Water for Injection (WFI) for drug manufacturing, large-scale bioreactors, and extensive sterile environments, ensuring adherence to the strictest global GMP standards.

- Desalination Plants (Core System): Functions as the core reverse osmosis system in large-scale seawater purification and brackish water desalination plants, transforming saline sources into fresh water for various end-uses.

- Chemical Water Treatment Plants (Central Purification): Serves as the central purification unit in vast chemical water treatment plants, supplying immense quantities of high-purity water for complex chemical formulations, industrial reactions, and significantly reducing the chemical load on subsequent treatment steps.

- Mining & Metals Industry: For large-volume process water, mineral extraction, and advanced treatment of challenging water streams within large-scale mining and metals processing operations.

- Wastewater Treatment & Reuse (Advanced Systems): Employed in multi-stage advanced wastewater treatment facilities to produce high-quality effluent suitable for industrial reuse, agricultural irrigation, or even indirect potable reuse, promoting water conservation.

장점 1

이점 2

관련 제품

연관 상품

자주 묻는 질문

Q1: 역삼투압 시스템의 수명은 얼마나 되나요?

역삼투압 시스템의 수명은 수질과 유지 관리에 따라 달라집니다. 일반적으로 멤브레인의 수명은 2~3년이며, 시스템 자체는 적절한 관리를 통해 10년 이상 지속될 수 있습니다.

Q2: 다양한 수질 조건에 따라 시스템을 맞춤 설정할 수 있나요?

예, 모든 시스템은 완벽하게 사용자 정의할 수 있습니다. 고객의 수질 보고서와 애플리케이션 요구 사항을 분석하여 맞춤형 솔루션을 제공합니다.

Q3: STARK 장비는 어떤 표준을 준수하나요?

당사의 제품은 CE, ISO 9001을 준수하며 요청에 따라 특정 지역 규정 또는 산업 표준을 충족하도록 설계할 수 있습니다.

Q4: STARK RO 시스템의 배송 시간은 어떻게 되나요?

표준 시스템은 7~15일 이내에 배송됩니다. 맞춤형 주문의 경우 복잡성에 따라 리드 타임이 20~25일로 연장될 수 있습니다.

Q5: 기술 지원이나 설치 안내를 제공하나요?

예. 전체 기술 문서와 비디오를 통한 원격 지원을 제공하며, 요청 시 엔지니어를 해외로 파견할 수 있습니다.

Q6: 견적에는 무엇이 포함되나요?

견적에는 전체 RO 시스템, 제어판, 펌프, 전처리 장치 및 필요한 모든 피팅이 포함됩니다. 요청 시 설치 도구와 예비 부품도 포함될 수 있습니다.