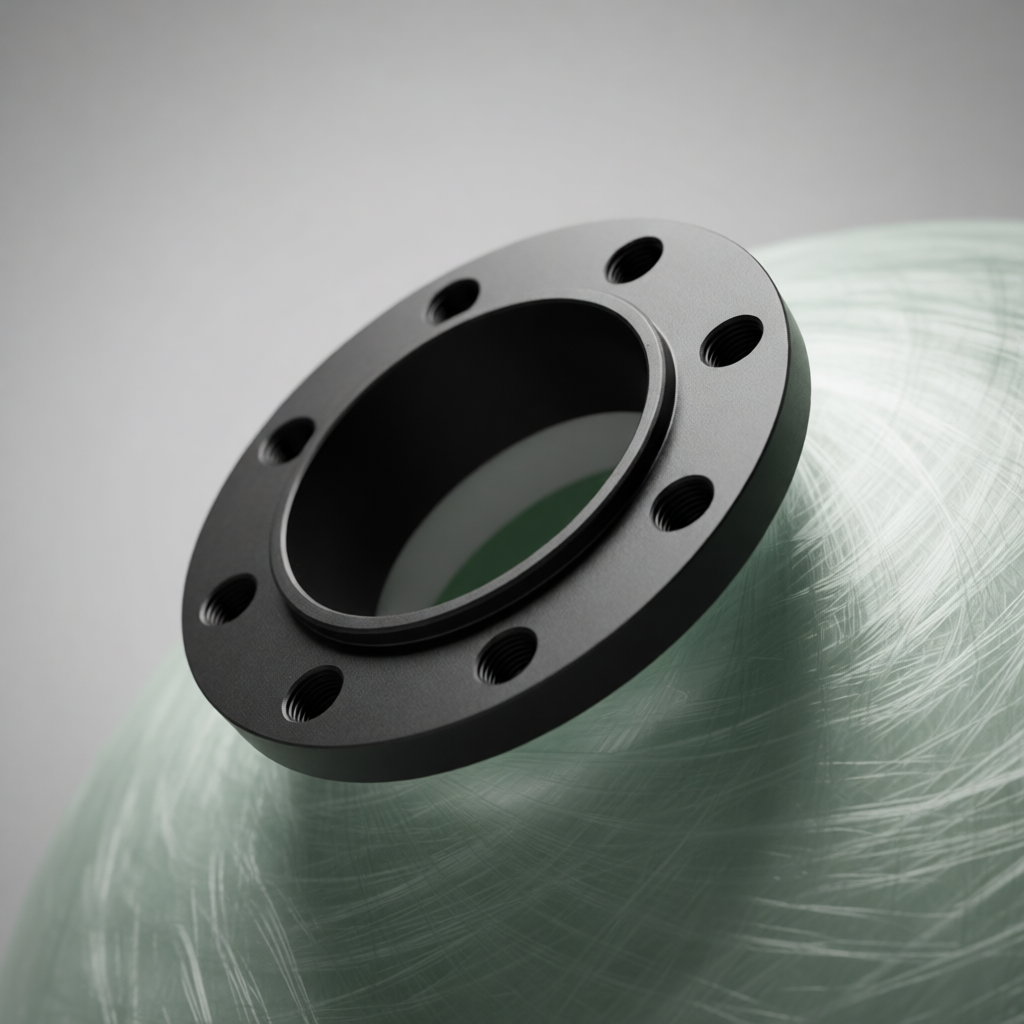

Stark Industrial 6″ Flange Pressure Vessel Series (Heavy Duty)

The Stark industrial **6″ Flange pressure vessel** is engineered for high-volume filtration applications. Featuring a secure 6-inch flange top opening, this heavy-duty tank series (36″-72″ diameter) is designed for municipal water treatment and large-scale industrial plants requiring maximum flow rates and absolutely leak-proof pipe connections.

제품 설명

Engineered for the Toughest Industrial Demands.

The Stark **6″ Flange pressure vessel** series represents the pinnacle of large-scale composite manufacturing. Unlike threaded connections which can be prone to leaks under the stress of large piping systems, our 6-inch flange interface offers a robust, bolted connection point compatible with standard DN150 industrial piping. This ensures zero-leakage performance even under high vibration or pressure surges common in desalination plants and municipal facilities.

Our proprietary multi-axis winding process ensures that even our largest 72-inch vessels maintain structural rigidity and uniform pressure distribution, offering a superior, corrosion-resistant alternative to rubber-lined steel tanks.

Installation & Standard Data:

Proper flange alignment and bolt torque are critical for large vessel safety. For detailed flange dimension drawings (ANSI/DIN), bolt circle specifications, and installation torque guides, please reference the technical documentation at our specialized manufacturing division:

Stark Tank Manufacturing – 6″ Flange Series Technical Specs

.

제품 매개변수

Below are the verified specifications for our 6″ Flange top-mount series. These heavy-duty tanks are designed for industrial applications requiring high flow rates.

| 모델 | 볼륨 용량 | Dimensions (Dia x H) | Flow Rate (m³/h) | B2B Quote | ||

|---|---|---|---|---|---|---|

| 유형 | US Gal | Liters | Nominal | mm | (Filter/Softener) | Action |

| STK-3694 | 318.4 | 1205 | 36″ x 94″ | Ø900 x 2465 | 7.6-10 / 12-19 | Inquiry |

| STK-4094 | 351.9 | 1332 | 40″ x 94″ | Ø1000 x 2430 | 9.4-11.7 / 15.7-23.5 | Inquiry |

| STK-4272 | 290.6 | 1100 | 42″ x 72″ | Ø1080 x 1850 | 15-25 / 26-30 | Inquiry |

| STK-4872 | 345.6 | 1308 | 48″ x 72″ | Ø1200 x 1880 | 13.5-17 / 22.6-34 | Inquiry |

| STK-4894 | 504.4 | 1909 | 48″ x 94″ | Ø1200 x 2430 | 13.5-17 / 22.6-34 | Inquiry |

| STK-6083 | 570.1 | 2158 | 60″ x 83″ | Ø1500 x 2120 | 21-27 / 35-53 | Inquiry |

| STK-6094 | 710.2 | 2688 | 60″ x 94″ | Ø1500 x 2430 | 21-27 / 35-53 | Inquiry |

| STK-6383 | 681.6 | 2580 | 63″ x 83″ | Ø1600 x 2100 | 25-45 / 46-56 | Inquiry |

| STK-7294 | 940.8 | 3561 | 72″ x 94″ | Ø1800 x 2400 | 30-40 / 50-76 | Inquiry |

*Note: US dimensions are nominal. Flow rates are for reference only. Please consult our engineers for precise system design.

해당 산업

- Municipal Water Treatment:

Large-scale sand and carbon filtration for city water supplies, removing sediment and contaminants at high throughput. - Seawater Desalination:

Pre-treatment filtration for SWRO plants, utilizing corrosion-resistant FRP to withstand aggressive saline environments. - Power Plant Cooling Systems:

Side-stream filtration for cooling towers to reduce suspended solids and prevent heat exchanger fouling.

장점 1

Secure Flange Connection

For vessels exceeding 36 inches in diameter, threaded connections are often insufficient. Stark’s 6-inch flange top opening provides a standardized, bolted connection that eliminates the risk of thread stripping or cross-threading during installation.This design allows for the secure attachment of heavy industrial piping (steel or large diameter UPVC) and ensures a reliable seal capable of withstanding system vibration and hydraulic shock.이점 2

Massive Capacity, Minimal Maintenance

With diameters up to 72 inches, these vessels hold thousands of liters of media, allowing for extended service runs between backwashes. Unlike traditional rubber-lined steel tanks, Stark FRP vessels are inherently rust-proof and require zero painting or lining maintenance.This significantly reduces the total cost of ownership (TCO) for large-scale projects while providing a service life that often exceeds 10 years in harsh conditions.관련 제품

연관 상품

자주 묻는 질문

Q1: 역삼투압 시스템의 수명은 얼마나 되나요?

역삼투압 시스템의 수명은 수질과 유지 관리에 따라 달라집니다. 일반적으로 멤브레인의 수명은 2~3년이며, 시스템 자체는 적절한 관리를 통해 10년 이상 지속될 수 있습니다.

Q2: 다양한 수질 조건에 따라 시스템을 맞춤 설정할 수 있나요?

예, 모든 시스템은 완벽하게 사용자 정의할 수 있습니다. 고객의 수질 보고서와 애플리케이션 요구 사항을 분석하여 맞춤형 솔루션을 제공합니다.

Q3: STARK 장비는 어떤 표준을 준수하나요?

당사의 제품은 CE, ISO 9001을 준수하며 요청에 따라 특정 지역 규정 또는 산업 표준을 충족하도록 설계할 수 있습니다.

Q4: STARK RO 시스템의 배송 시간은 어떻게 되나요?

표준 시스템은 7~15일 이내에 배송됩니다. 맞춤형 주문의 경우 복잡성에 따라 리드 타임이 20~25일로 연장될 수 있습니다.

Q5: 기술 지원이나 설치 안내를 제공하나요?

예. 전체 기술 문서와 비디오를 통한 원격 지원을 제공하며, 요청 시 엔지니어를 해외로 파견할 수 있습니다.

Q6: 견적에는 무엇이 포함되나요?

견적에는 전체 RO 시스템, 제어판, 펌프, 전처리 장치 및 필요한 모든 피팅이 포함됩니다. 요청 시 설치 도구와 예비 부품도 포함될 수 있습니다.