수처리 플랜트 RO 멤브레인 필터 카트리지 요소 역삼투 멤브레인 교체

제품 설명

Each membrane element is housed in a durable, chemical-resistant wrap that ensures stability under varying pressures and temperatures. With consistent salt rejection rates (up to 98.5%) and a high permeate flow rate, our RO membrane cartridges are ideal for applications that demand purity, efficiency, and reliability.

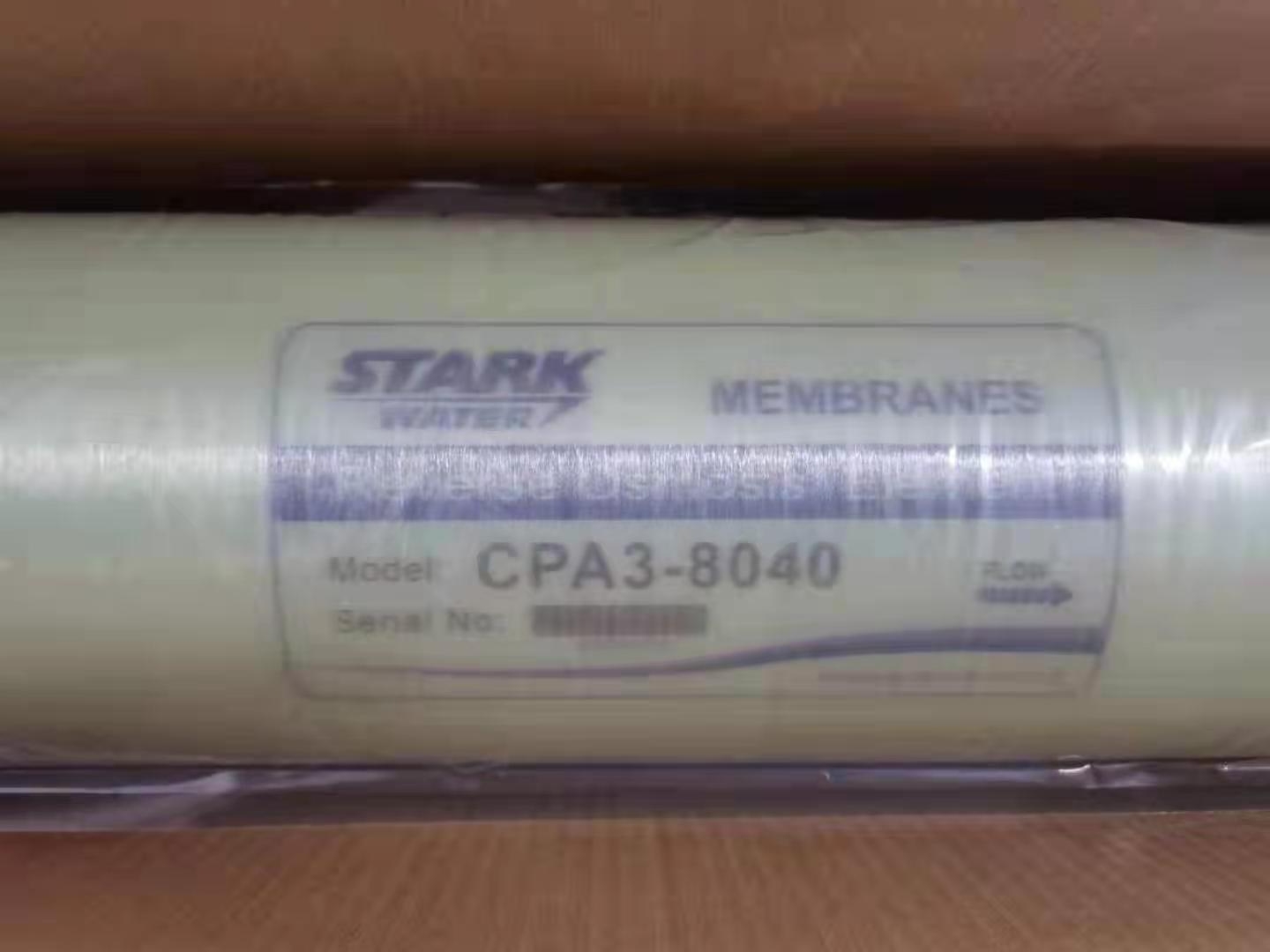

STARK provides a wide range of configurations—including 4040 and 8040 sizes—suitable for small commercial RO systems to large-scale municipal water plants. Each membrane undergoes quality control testing to ensure performance consistency before shipping.

Whether used as a replacement cartridge or as part of a new installation, STARK’s membrane elements are designed to integrate smoothly with standard reverse osmosis systems, offering minimized downtime and easy replacement procedures. The membranes are suitable for brackish water, tap water, and pre-treated seawater systems.

Industries we serve include pharmaceutical manufacturing, food & beverage processing, electronics production, and municipal drinking water treatment. The cartridges also support custom OEM/ODM requirements to match specialized RO system designs.

제품 매개변수

- Product Type: Reverse Osmosis Membrane Cartridge

- Membrane Material: Thin-Film Composite (TFC)

- Available Sizes: 4040 / 8040 (Custom sizes available upon request)

- Operating Pressure: 150 – 300 psi (10 – 20 bar)

- Max Operating Temperature: 45°C (113°F)

- Salt Rejection Rate: ≥98.5%

- Permeate Flow Rate: 2400 – 11000 GPD (depending on size)

- pH Range (Continuous Operation): 3 – 10

- Chlorine Tolerance: <0.1 ppm (pre-treatment required)

- Connector Type: Standard male/female end caps or customized fittings

- Certifications: ISO 9001, CE (optional NSF on request)

해당 산업

- Pharmaceutical & Biotech: Used in ultra-pure water systems for drug formulation, rinsing, and lab-grade applications.

- Food & Beverage: Applied in bottled water production, ingredient blending, and CIP rinse cycles to meet hygiene standards.

- Electronics & Semiconductors: Ensures ultrapure water quality for chip cleaning, circuit board manufacturing, and precision rinsing processes.

- Municipal Water Supply: Integrated into public water treatment plants for removing hardness, heavy metals, and pathogens.

- Seawater Desalination: Used in brackish and seawater RO systems for producing potable or industrial-grade water.

- Chemical & Textile Industries: Facilitates demineralized water generation for chemical blending, dyeing, and rinsing operations.

- Commercial Buildings & Institutions: Installed in schools, hospitals, and hotels to ensure safe and reliable water delivery.

장점 1

Advantage 1: Superior Filtration Efficiency

The STARK reverse osmosis membrane cartridge delivers exceptional salt rejection performance, achieving up to 98.5% removal of dissolved solids, organics, and heavy metals. Its advanced thin-film composite structure ensures optimal filtration precision while maintaining high flow rates. This results in reduced energy consumption and enhanced operational efficiency, especially in large-scale water treatment applications. Whether you’re operating in a pharmaceutical-grade clean environment or a high-demand industrial process, the membrane maintains consistent water quality over extended operation periods.이점 2

Advantage 2: Durability and Easy Maintenance

Constructed with robust, high-performance materials, the STARK reverse osmosis membrane cartridge is engineered to withstand harsh water conditions and long operational hours. Its chlorine-tolerant design (≤0.1 ppm) and broad pH compatibility (3–10) help reduce fouling and membrane degradation, ensuring extended service life. The standardized 4040 and 8040 configurations allow for easy installation and replacement, minimizing system downtime. With minimal cleaning cycles required and lower frequency of replacements, users benefit from reduced maintenance costs and higher system uptime—making it a cost-effective long-term solution for continuous water purification needs.관련 제품

연관 상품

자주 묻는 질문

Q1: 역삼투압 시스템의 수명은 얼마나 되나요?

역삼투압 시스템의 수명은 수질과 유지 관리에 따라 달라집니다. 일반적으로 멤브레인의 수명은 2~3년이며, 시스템 자체는 적절한 관리를 통해 10년 이상 지속될 수 있습니다.

Q2: 다양한 수질 조건에 따라 시스템을 맞춤 설정할 수 있나요?

예, 모든 시스템은 완벽하게 사용자 정의할 수 있습니다. 고객의 수질 보고서와 애플리케이션 요구 사항을 분석하여 맞춤형 솔루션을 제공합니다.

Q3: STARK 장비는 어떤 표준을 준수하나요?

당사의 제품은 CE, ISO 9001을 준수하며 요청에 따라 특정 지역 규정 또는 산업 표준을 충족하도록 설계할 수 있습니다.

Q4: STARK RO 시스템의 배송 시간은 어떻게 되나요?

표준 시스템은 7~15일 이내에 배송됩니다. 맞춤형 주문의 경우 복잡성에 따라 리드 타임이 20~25일로 연장될 수 있습니다.

Q5: 기술 지원이나 설치 안내를 제공하나요?

예. 전체 기술 문서와 비디오를 통한 원격 지원을 제공하며, 요청 시 엔지니어를 해외로 파견할 수 있습니다.

Q6: 견적에는 무엇이 포함되나요?

견적에는 전체 RO 시스템, 제어판, 펌프, 전처리 장치 및 필요한 모든 피팅이 포함됩니다. 요청 시 설치 도구와 예비 부품도 포함될 수 있습니다.