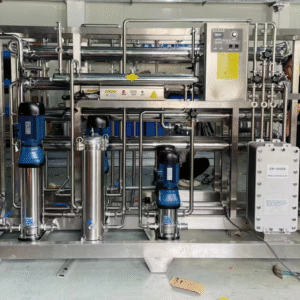

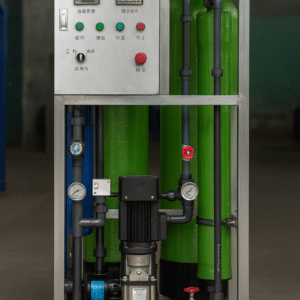

Stark 500 LPH automatic stainless steel two-stage reverse osmosis filters system EDI device

Stark 500 LPH automatic stainless steel two-stage reverse osmosis filters system EDI deviceStark 500 LPH automatic stainless steel two-stage reverse osmosis filters system EDI device

Achieve unparalleled water purity with Stark Water’s 500 LPH Automatic Stainless Steel Two-Stage Reverse Osmosis Filters System EDI Device. This advanced reverse osmosis filters system EDI device delivers continuous, chemical-free ultra-pure water, ideal for sensitive applications in pharmaceuticals, electronics, and laboratories requiring the highest levels of purification.

제품 설명

In industries where the slightest impurity can compromise product integrity, process efficiency, or analytical accuracy, ultra-pure water is an absolute necessity. The Stark Water 500 LPH Automatic Stainless Steel Two-Stage Reverse Osmosis Filters System EDI Device is meticulously engineered to meet these exacting demands, providing a compact yet powerful solution for continuous production of ultra-pure water. This system represents a fusion of advanced filtration technologies, ensuring uncompromised purity and reliable performance.

The Precision of a Two-Stage Reverse Osmosis Filters System

Our system begins with a sophisticated two-stage reverse osmosis filters system. While a single RO stage effectively removes the majority of dissolved solids and contaminants, a second RO pass further refines the water. This sequential purification significantly reduces residual ions, ensures higher overall contaminant rejection, and provides an exceptionally pure feed for the subsequent EDI process. This robust pre-treatment is crucial for maximizing the efficiency and extending the lifespan of the EDI device. With a capacity of 500 LPH (500 liters per hour or 0.5 m³/hr), this system is ideally suited for small to medium-scale industrial, laboratory, and commercial operations requiring consistent volumes of highly purified water.

Integrated EDI Device: Chemical-Free Ultra-Pure Water Polishing

The true heart of this ultra-pure water solution is the seamlessly integrated EDI device (Electrodeionization). Taking the high-quality permeate from the two-stage RO, the EDI device elevates water purity to ultra-pure levels, typically achieving resistivity values between 16 and 18 MΩ·cm (megohms per centimeter). EDI technology uniquely combines ion exchange resins and ion-selective membranes with an applied electrical current to continuously remove remaining dissolved ions. The key advantage of this EDI device is its chemical-free regeneration:

- No Hazardous Chemicals: Eliminates the need for costly and dangerous acids and caustics traditionally used to regenerate ion exchange resins, enhancing operator safety.

- Continuous Operation: Provides an uninterrupted supply of ultra-pure water, avoiding downtime associated with batch chemical regeneration cycles.

- Reduced Waste: Minimizes the generation of hazardous chemical waste, aligning with environmental sustainability goals and reducing disposal costs.

This ensures the final output water is not only exceptionally pure but also produced with optimal safety and environmental responsibility.

Robust Stainless Steel Construction & Automated Operation

The STARK 500 LPH system is built with durability and hygiene in mind, featuring comprehensive stainless steel construction (typically SUS304 or SUS316L for all critical wetted parts and frame). Stainless steel offers superior corrosion resistance, structural integrity, and hygienic properties, crucial for high-purity water applications. Furthermore, the system is fully automatic, incorporating an intelligent control system (PLC with HMI) that provides real-time monitoring of water quality (e.g., conductivity/resistivity at multiple points), pressure, and flow. Automated functions like auto-flush and cleaning-in-place (CIP) cycles simplify operation and maintenance, ensuring consistent performance, minimal manual intervention, and reliable ultra-pure water output for sensitive processes.

제품 매개변수

Stark Water’s 500 LPH Automatic Stainless Steel Two-Stage Reverse Osmosis Filters System EDI Device is engineered for continuous production of ultra-pure water. Here are its key technical specifications:

| 매개변수 | 사양 / 사용자 지정 옵션 |

|---|---|

| 핵심 키워드 포커스 | reverse osmosis filters system EDI device design and capabilities. |

| Pure Water Capacity | 500 Liters Per Hour (LPH) / 0.5 m³/hr / approx. 2.2 GPM of ultra-pure water. Custom capacities available. |

| System Configuration | Automatic Two-Stage Reverse Osmosis (RO) followed by Electrodeionization (EDI). |

| RO Membrane Type | High-rejection Thin-Film Composite (TFC) RO Membranes (e.g., 4040 or 2540 series, quantity sized for 500LPH output, two stages). |

| EDI Module | Integrated EDI device module for continuous deionization (e.g., Ionpure, Evoqua, or equivalent high-performance module). |

| Product Water Quality | Resistivity: Typically 16 – 18 MΩ·cm @ 25°C (conductivity <0.1 μS/cm). Significantly reduced TOC, Silica, Boron, and particles. Meets USP, EP, JP purified water standards. |

| Feed Water Requirement | Municipal Water, Well Water, or Brackish Water, adequately pre-treated for the 1st stage RO. 2nd stage RO is fed by 1st stage permeate, and EDI is fed by 2nd stage permeate. |

| Overall Salt Rejection | ≥99.8% after 2nd stage RO. Final ion removal by EDI. |

| Water Recovery Rate | Typically 65% – 80% (overall system recovery from raw water). Dependent on raw water quality. |

| High-Pressure Pumps | Multiple energy-efficient, stainless steel pumps for 1st RO, 2nd RO, and EDI feed. |

| Pre-treatment System |

|

| 전원 공급 장치 | 3 Phase, 380V/415V/460V, 50Hz/60Hz (Customizable). |

| 제어 시스템 | Fully Automatic PLC Control with HMI, real-time online monitoring of all critical parameters, auto-flush, CIP cycles, safety interlocks. Remote monitoring capability. |

| Construction Material |

|

| Dimensions (Approximate) | Compact skid-mounted design (e.g., L 2000mm x W 1000mm x H 1800mm). |

| 작동 온도 | 5°C – 45°C. |

| Certification | Designed to meet relevant international standards (e.g., ISO, CE, ASME, GMP, USP, EP, JP for water quality). |

해당 산업

The STARK 500 LPH Automatic Stainless Steel Two-Stage Reverse Osmosis Filters System EDI Device is a critical asset for industries demanding the absolute highest purity of water, where continuous, chemical-free ultra-pure water is essential at a medium-small scale. Its advanced capabilities make it ideal for:

- Pharmaceutical Industry (PW/WFI pre-treatment): Essential for producing Purified Water (PW), pre-treatment for Water for Injection (WFI), and Highly Purified Water (HPW) in strict compliance with pharmacopoeia standards (USP, EP, JP), used in drug formulation, API production, and sterile rinsing.

- Electronics & Semiconductor Manufacturing (Component Rinsing/Lab): Crucial for producing Ultra-Pure Water (UPW) used in smaller-scale fabrication lines, component rinsing, and cleanroom environments, where even sub-trace ions cause critical defects.

- Laboratories & Research Facilities: Produces analytical-grade water (Type I/II) for highly sensitive laboratory experiments, glassware washing, and reagent preparation, ensuring accurate and reproducible results.

- Power Generation (Auxiliary Systems/Battery Water): Used for producing ultra-pure boiler feed water for smaller high-pressure boilers, or for battery make-up water, preventing scaling and corrosion.

- High-Purity Chemical Manufacturing: Provides ultra-pure water for sensitive chemical reactions, diluting high-purity chemicals, and creating specialized solutions where ion contamination must be strictly avoided.

- Medical Device Manufacturing (Smaller Scale): Provides ultra-pure water for final rinsing and cleaning of medical devices to ensure safety and quality.

- Cosmetics & Personal Care (High-End): For producing ultra-pure water for high-end cosmetic formulations where water quality directly impacts product stability and safety.

- Hospital Central Sterilization Supply Departments (CSSD): Providing ultra-pure water for instrument washing and sterilization equipment where high-purity water improves efficiency and longevity.

- Pilot Plants & R&D: Ideal for testing and scaling up processes requiring ultra-pure water without large-scale infrastructure.

장점 1

이점 2

관련 제품

연관 상품

자주 묻는 질문

Q1: 역삼투압 시스템의 수명은 얼마나 되나요?

역삼투압 시스템의 수명은 수질과 유지 관리에 따라 달라집니다. 일반적으로 멤브레인의 수명은 2~3년이며, 시스템 자체는 적절한 관리를 통해 10년 이상 지속될 수 있습니다.

Q2: 다양한 수질 조건에 따라 시스템을 맞춤 설정할 수 있나요?

예, 모든 시스템은 완벽하게 사용자 정의할 수 있습니다. 고객의 수질 보고서와 애플리케이션 요구 사항을 분석하여 맞춤형 솔루션을 제공합니다.

Q3: STARK 장비는 어떤 표준을 준수하나요?

당사의 제품은 CE, ISO 9001을 준수하며 요청에 따라 특정 지역 규정 또는 산업 표준을 충족하도록 설계할 수 있습니다.

Q4: STARK RO 시스템의 배송 시간은 어떻게 되나요?

표준 시스템은 7~15일 이내에 배송됩니다. 맞춤형 주문의 경우 복잡성에 따라 리드 타임이 20~25일로 연장될 수 있습니다.

Q5: 기술 지원이나 설치 안내를 제공하나요?

예. 전체 기술 문서와 비디오를 통한 원격 지원을 제공하며, 요청 시 엔지니어를 해외로 파견할 수 있습니다.

Q6: 견적에는 무엇이 포함되나요?

견적에는 전체 RO 시스템, 제어판, 펌프, 전처리 장치 및 필요한 모든 피팅이 포함됩니다. 요청 시 설치 도구와 예비 부품도 포함될 수 있습니다.