RO membrane replacement guide: how often to change 1812/4040/8040 membranes, the exact step-by-step procedure, tools, safety, and post-replacement checks.

Shop RO Membranes Open RO Sizing Calculator

RO Membrane Replacement Frequency (1812/4040/8040)

- Household 1812/2012: 18–36 months with proper pretreatment.

- Commercial 4040: 12–24 months depending on SDI and scaling control.

- Industrial 8040 BWRO/SWRO: 2–5 years under stable operation and CIP.

For faster sourcing, see our RO membrane replacement kits.

How Often Should You Replace an RO Membrane?

Household 1812/2012

18–36 months (municipal feed, good pretreatment)

Commercial 3012/4014/4040

12–24 months (depends on SDI, scaling control)

Industrial 8040 BWRO

2–3 years (stable pre-treatment & CIP)

Industrial 8040 SWRO

3–5 years (offshore/municipal seawater quality)

Use performance triggers below rather than time alone; replace when permeate quality or flow cannot be restored by cleaning.

When to Replace: Objective Triggers

- Permeate TDS ↑ and salt rejection falls by > 2–3% from baseline.

- Permeate flow ↓ > 15–25% vs. clean baseline at same temperature.

- Pressure drop (ΔP) ↑ across vessel/stage > 15–20% after cleaning.

- Unable to recover performance after proper chemical cleaning (acid/alkaline/bio).

Reference: FilmTec™ Reverse Osmosis Membranes Technical Manual (DuPont) – operating limits, normalization & replacement diagnostics.

What Affects RO Membrane Lifespan

- Feedwater & Pretreatment: SDI/NTU, chlorine/chloramine control, hardness/iron/manganese.

- Operating Design: Recovery, cross-flow velocity, temperature correction, permeate backpressure.

- Scaling & Fouling Control: Antiscalant dosing, cartridge filtration, periodic CIP.

- Shutdown & Preservation: Biogrowth during idle periods without preservation.

See related products in Accessories or RO Systems.

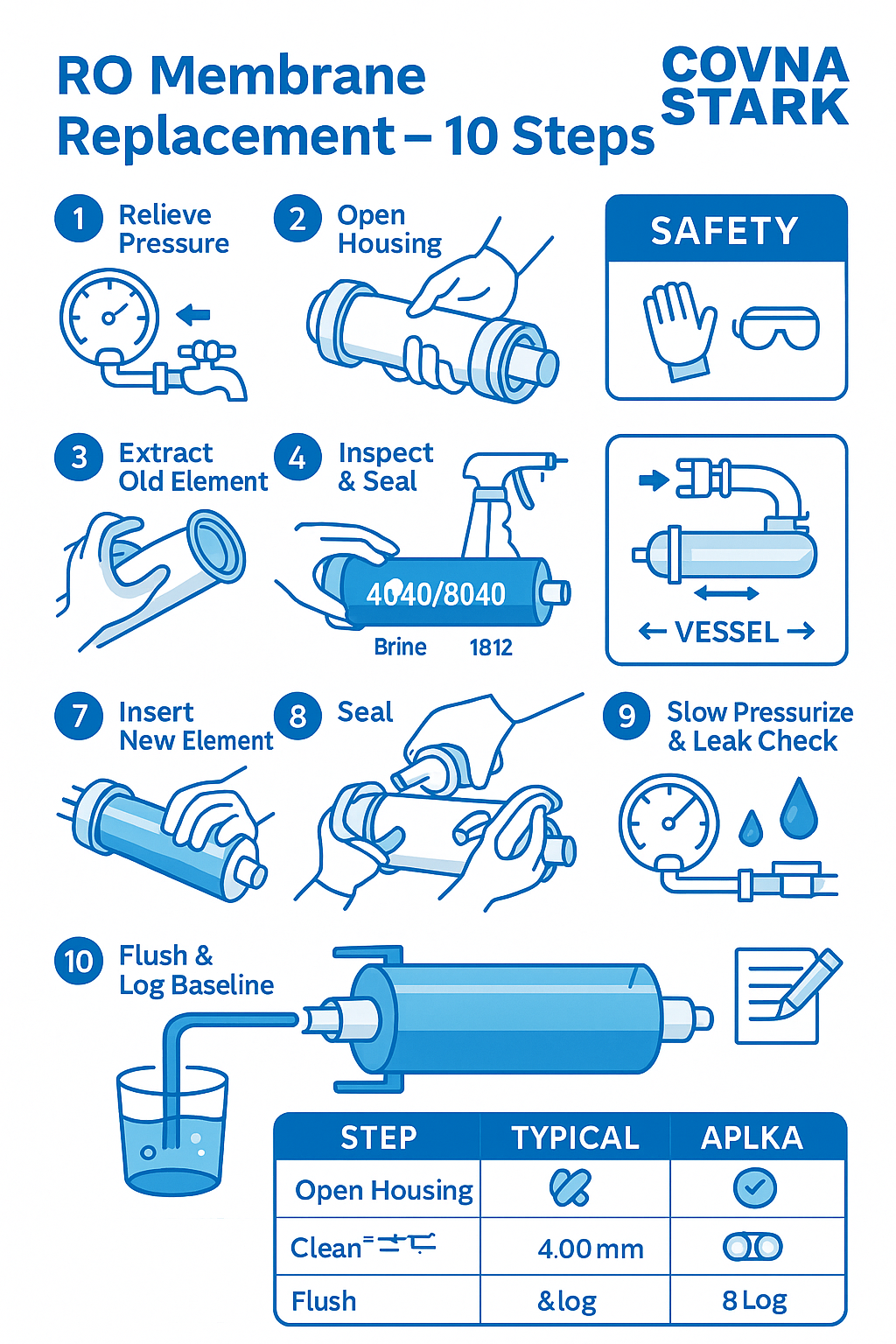

Tools & Parts You’ll Need

- PPE: safety glasses, gloves; bucket & absorbent pads

- Wrenches for housings / end caps; torque where applicable

- New RO membrane (1812/4040/8040), O-rings, food-grade lubricant

- Sanitizer (e.g., 1–2% sodium hypochlorite for housings only if compatible), preservative if needed

- TDS/conductivity meter; pressure gauges at feed/concentrate/permeate

Safety & Preparation

- Isolate and depressurize the system completely; lockout/tagout pumps.

- Close feed and concentrate valves; open vents to release pressure.

- Bypass or drain the housing; protect electrical components from spills.

- Mark flow direction and vessel positions for correct reassembly.

- Sanitize housing if required; check and replace worn O-rings.

RO Membrane Replacement – Step by Step

- Relieve Pressure – Verify zero pressure on gauges; crack vents slowly.

- Open Housing – Remove end cap carefully; note brine/permeate port orientation.

- Extract Old Element – Pull using pliers/strap; protect permeate tube.

- Inspect & Clean – Rinse housing; wipe debris; check for scaling/biofilm.

- Prep New Element – Verify model; wet O-rings with food-grade lube.

- Insert – Align the permeate tube into the interconnector; push until fully seated.

- Seal – Reinstall end cap with new O-rings; torque evenly to spec.

- Repressurize Slowly – Open feed slightly; check leaks; then ramp to design pressure.

- Flush – Divert initial permeate to drain (household 15–30 min; industrial as per vendor).

- Record Baseline – Log temperature-corrected permeate flow, rejection, and ΔP.

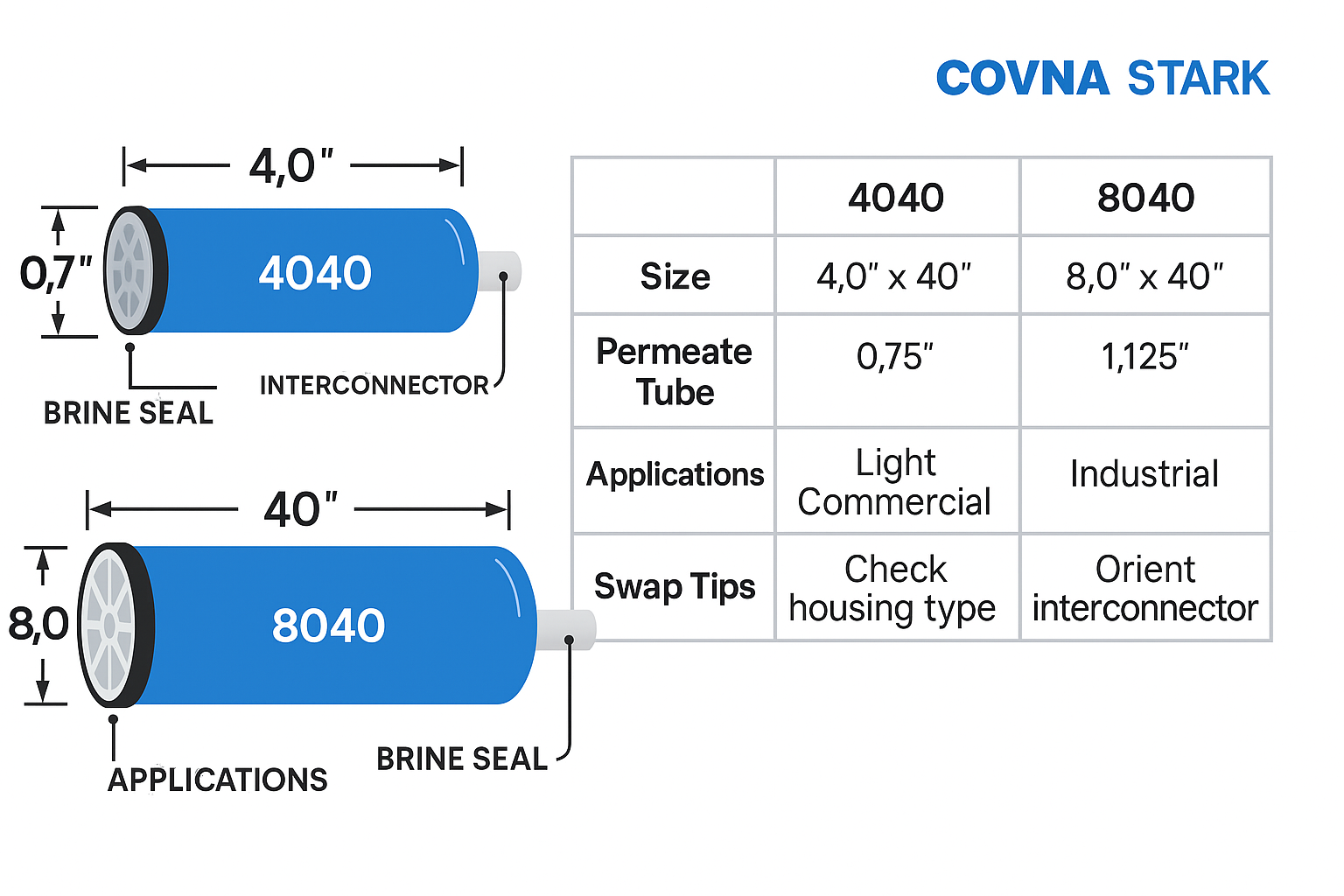

1812 household: open faucet and tank valve, discard first tank. 4040/8040: verify interconnectors and brine seal orientation; observe vessel arrow direction.

After Replacement: QA & Baseline

- Measure permeate TDS and flow at stable temperature; record as new baseline.

- Check ΔP per stage; investigate abnormal rise (>15–20%).

- Calibrate online sensors; re-enable alarms for high TDS/pressure.

Try our RO sizing calculator to confirm operating points.

Common Sizes & Cross-Reference

| 유형 | Typical Size | Permeate Tube | Where Used | Swap Tips |

|---|---|---|---|---|

| 1812 / 2012 | 1.8″ × 12″ | 0.5″ | Household under-sink | Check housing compatibility; discard first tank after change |

| 4040 | 4.0″ × 40″ | 0.75″ | Commercial / light industrial | Confirm brine seal direction; verify vessel end-cap O-rings |

| 8040 | 8.0″ × 40″ | 1.125″ | Industrial BWRO / SWRO | Check interconnectors; follow torque values on end caps |

Need help matching a model? Contact Covna Stark with feedwater and flow requirements.

RO Membrane Replacement FAQs

Is a membrane the same as a filter?Can I just clean instead of replacing?How long should I flush a new membrane?What damages membranes?Do I need to change flow restrictors?

Get a Quote or Technical Pack

Tell us your feed TDS, temperature, target permeate flow, and recovery. Our engineer will send a model match and price within 24h.