Reviewed by Stark Water Process Engineering Team • Last updated: 20 Oct 2025

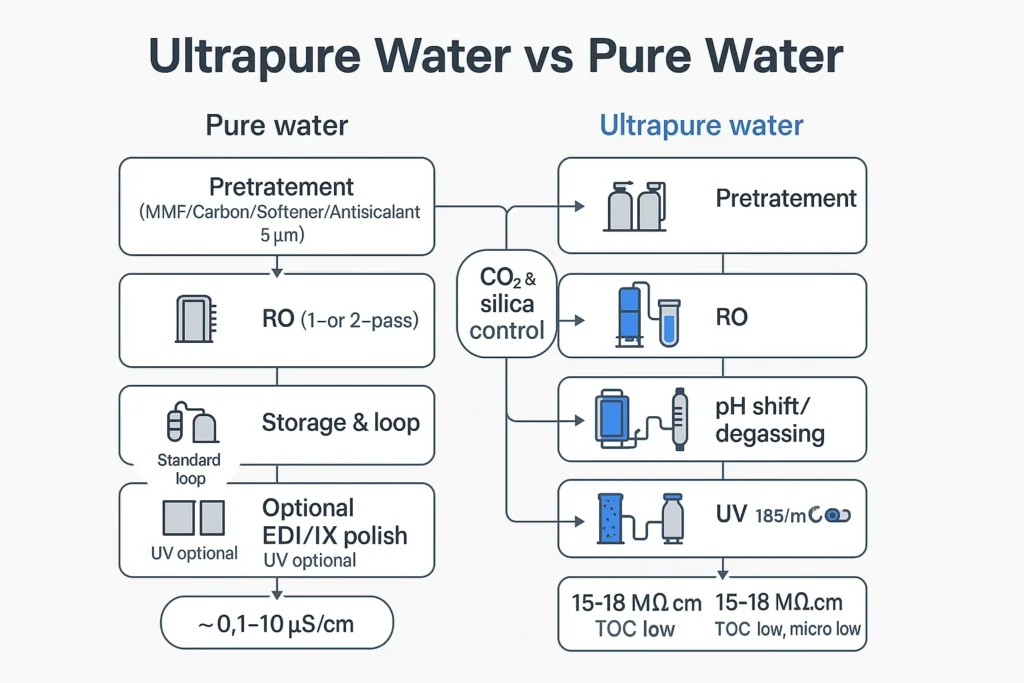

Ultrapure water vs pure water: both are purified, but they serve different quality targets and use cases. Pure water generally refers to RO-grade industrial or potable purified water (≈0.1–10 µS/cm). Ultrapure water (UPW) is engineered for the tightest ionic, TOC, particulate and microbial limits—typically ≥15–18 MΩ·cm at 25 °C with UV and final 0.2 µm filtration. The tables and flow below help you choose the right train, size key elements and avoid common pitfalls.

Snapshot comparison: ultrapure water vs pure water

| 매개변수 | Pure water (industrial) | Ultrapure water (UPW) | 참고 |

|---|---|---|---|

| Typical conductivity / resistivity | ~0.1–10 µS/cm (0.1–10 MΩ·cm-1 equivalent) | 0.067–0.055 µS/cm (15–18 MΩ·cm) | Reported at 25 °C; CO₂ depresses resistivity. |

| Core process | Pretreatment → 1-/2-pass RO → storage/loop → optional polish (IX/EDI) → 0.2 µm | Pretreatment → RO → EDI or mixed bed → UV (185/254) → 0.2 µm → hygienic loop | Two-pass RO and degassing help silica/boron/CO₂ control. |

| Micro/TOC control | As needed for process; free-chlorine or UV, 0.2 µm | UV (185/254), low-TOC materials, sanitary design | Hygienic 316L loop and validated sanitization for UPW. |

| Typical uses | Boiler makeup, food & beverage, general industry, drinking water polishing | Semiconductor, battery plants, precision optics, labs (DI/UPW) | UPW supports the tightest ionic/organic/microbial specs. |

| CapEx / OpEx | Lower; fewer polishing steps | Higher; polishing, UV, hygienic loop | EDI lowers chemical handling vs IX regeneration. |

What “pure water” means in industry

Common trains

- RO-based: multimedia → carbon → softening/antiscalant → cartridge → RO (1-/2-pass) → storage & loop → optional IX/EDI polish → 0.2 µm end filter.

- IX-based: pretreatment → cation/anion beds → mixed bed → microfilter (used when low silica/boron and CO₂ are manageable).

Quality ranges

- General industrial: 1–10 µS/cm; High-purity/boiler: 0.1–1.0 µS/cm.

- Micro control per process (e.g., beverage/bioburden) and materials compatibility.

What is an ultrapure water (UPW) system?

Modern UPW options

- RO → EDI → UV (185/254) → 0.2 µm (no bulk regenerants).

- RO → mixed bed (rough + polish) → UV → 0.2 µm (deep ionic polish; requires acid/caustic).

- Two-pass RO with pH shift/degassing for boron/CO₂ → EDI → UV → final filter.

Acceptance & monitoring

- Online resistivity ≥15–18 MΩ·cm, low TOC, low silica/boron as specified.

- Validated sanitization, hygienic 316L loop, slope to drain, HEPA/UV-vented tanks.

Where each fits

- Ultrapure water: semiconductor/FPD, battery manufacturing, precision optics, PCB fabrication, high-end lab/analytical.

- Pure water: power-plant makeup, general industry rinse, food & beverage polishing, pharma pretreatment, potable polishing.

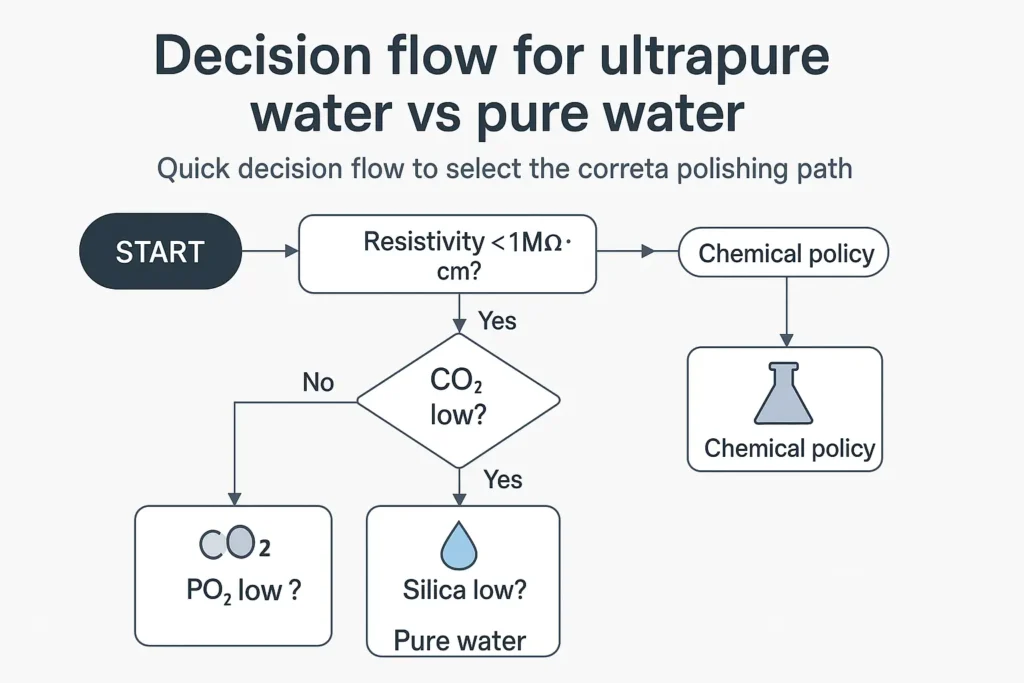

Selection guide: choosing ultrapure water vs pure water

- Define quality target. If you need ≈0.1–1.0 µS/cm for boilers or industrial rinses, pure water (RO ± EDI/IX) is usually sufficient. If you need ≥15–18 MΩ·cm with tight TOC/micro, choose UPW.

- Check chemistry. High CO₂ or silica/boron? Use two-pass RO with pH shift/degassing, then EDI or mixed bed.

- Policy & staffing. Prefer EDI to reduce bulk chemicals and simplify O&M; choose mixed bed where deep ionic polish and regeneration logistics are acceptable.

- Uptime & cost. EDI enables continuous operation with low chemical exposure; IX offers robust polish with regeneration planning.

Design & sizing quick notes

- Pretreatment: multimedia → carbon → softening/antiscalant → 5 µm cartridge; manage iron/manganese and chlorine.

- Interstage conditioning: pH adjustment and/or degassing to lift RO silica/boron rejection; consider positive-charge RO where relevant.

- Materials & hygiene: SS316L, crevice-free connections, passivation, loop velocity 0.9–1.5 m/s, 0.2 µm end filters, validated sanitization.

- Instrumentation: feed/permeate/concentrate pressures, ΔP, flows, conductivity/resistivity, TOC (UPW), silica, ORP (disinfection), temperature.

Operations & maintenance

- RO: CIP at ΔP/flux triggers; track SDI and biofouling; typical life 3–5+ years with good pretreatment.

- EDI: trend current/voltage; periodic clean per OEM; minimal regenerants.

- IX/mixed bed: plan acid/caustic regeneration windows, neutralization and safety; monitor silica and sodium leakage.

- UV & final filters: replace lamps by hours/output; integrity-test 0.2 µm end filters.

- Documentation: logflows/pressures, CIP dates, sanitization records and acceptance tests.

Compliance & further reading

- ASTM D1193 (grades of reagent water).

- Water Quality Association (WQA) resources.

- ISPE guidance for pharmaceutical water systems.

FAQs: ultrapure water vs pure water

Is RO alone enough for ultrapure water?

No. Ultrapure water requires polishing—typically EDI or mixed bed—plus UV and final 0.2 µm filtration to meet ionic, TOC and microbial limits.

EDI or mixed bed for ultrapure water?

EDI eliminates bulk regeneration chemicals and favors continuous operation. Mixed bed gives deep polish with regeneration planning; choose based on chemical policy, uptime and staffing.

Why does dissolved CO₂ matter so much?

CO₂ depresses resistivity and consumes anion capacity. Two-pass RO with pH control and/or degassing improves downstream EDI/IX performance.

How do I reach low silica?

Use two-pass RO with pH shift and/or degassing, followed by EDI or mixed bed. Consider boron-aware RO and tight interstage control.

What’s a realistic target for “pure water” vs UPW?

Pure water commonly ranges from 0.1–1.0 µS/cm (high-purity industrial) to 1–10 µS/cm (general). UPW acceptance is typically ≥15–18 MΩ·cm with low TOC and validated hygiene.

Next steps (RFQ & internal links)

Share your RO permeate analysis and demand curve—we’ll size polishing paths, tank volumes and loop hydraulics, then propose a hygienic stainless-steel package.

- 견적 요청하기

- EDI vs Mixed Bed (selection guide)

- Reverse Osmosis System—Working Principle

- DI Water Storage Tank & Loop Design

- Stainless-Steel Tanks & Housings

Author: Stark Water Process Engineering Team — industrial water treatment specialists in RO, EDI/IX, UPW loops and hygienic stainless systems.