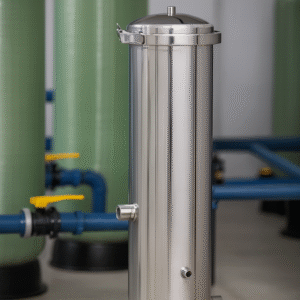

STARK Bag filter Concave cover single bag filter

Optimize your liquid filtration with the STARK Bag Filter Concave Cover Single Bag Filter. This efficient filtro de saco system offers robust, high-flow particulate removal with a unique concave cover design for secure sealing and easy operation. It’s an ideal solution for pre-filtration and clarification in various industrial and commercial water treatment applications.

Product Description

Efficiently removing suspended solids and impurities from liquids is a foundational requirement for numerous industrial and commercial processes. The STARK Bag Filter Concave Cover Single Bag Filter provides a highly effective and reliable solution for this critical task. This robust filtration system is engineered for high flow rates, significant dirt-holding capacity, and straightforward operation, making it an essential component for safeguarding downstream equipment and ensuring product quality.

High-Performance Bag Filtration

At its core, this system utilizes the proven efficacy of **bag filter** technology. Liquid flows into the housing, passes through a disposable filter bag, and exits as purified filtrate, while contaminants are efficiently trapped within the bag. This method is particularly effective for removing a wide range of particulate matter, from coarse sediments to finer suspended solids, depending on the micron rating of the installed filter bag. The large surface area of filter bags allows for high flow rates with minimal pressure drop, which is crucial for maintaining operational efficiency in continuous processes.

The system’s design ensures a high dirt-holding capacity, meaning filter bags can capture a substantial amount of impurities before requiring replacement. This translates to longer service intervals, reduced downtime, and lower operational costs compared to other filtration methods that may require more frequent cleaning or replacement.

Innovative Concave Cover & Secure Sealing

A distinguishing feature of the STARK Bag Filter is its unique **concave cover** design. This innovative cover not only provides exceptional structural integrity but also plays a crucial role in ensuring an **absolutely sealed design**. The concave shape helps to distribute pressure evenly across the sealing surface, enhancing the leak-proof performance of the filter housing. This robust sealing mechanism prevents any bypass of unfiltered liquid, guaranteeing that all fluid passes through the filter bag, thus consistently delivering the desired level of filtrate purity.

The secure sealing is further complemented by an easy-to-operate closure mechanism, allowing for quick and hassle-free access to the filter bag. This design prioritizes operator convenience, making bag change-outs simple and fast, which significantly minimizes maintenance time and maximizes system uptime.

Robust Construction for Industrial Demands

Built for the rigors of industrial environments, the STARK Bag Filter is constructed from durable materials, typically high-grade stainless steel (SUS304 or SUS316). This ensures excellent resistance to corrosion, chemicals, and high pressures, contributing to a long service life and reliable performance even in challenging operational conditions. The robust construction ensures the filter can withstand continuous use, providing a dependable solution for long-term filtration needs across various applications.

Product Parameter

The STARK Bag Filter Concave Cover Single Bag Filter is engineered for reliable and efficient liquid filtration. Here are its key technical specifications:

| Parameter | Especificação | ||

|---|---|---|---|

| Filter Type | Single Bag Filter (Compatible with standard filter bag sizes, e.g., #1, #2, #3, #4) | ||

| Core Keyword Focus | Bag Filter system design and functionality. | ||

| Design Feature | Concave Cover for enhanced sealing and strength. | ||

| Construction Material | Stainless Steel (SUS304 or SUS316, specific grade can be chosen based on application requirements). | ||

| Filtration Rating | Varies based on installed filter bag (e.g., from 0.5 micron to 800 micron). | ||

| Inlet/Outlet Connections | Threaded (NPT, BSPT) or Flanged (DIN, ANSI), common sizes from 1″ to 6″ or larger, depending on flow rate. | ||

| Max. Operating Pressure | Typically 0.6 MPa (6 Bar / 87 PSI) to 1.0 MPa (10 Bar / 145 PSI), customizable for higher pressures. | ||

| Max. Operating Temperature | Up to 100°C (depending on gasket materials and filter bag material). | ||

| Sealing Material | EPDM, Viton (FKM), Buna-N (NBR), Silicone (selected based on chemical compatibility and temperature). | ||

| Closure Type | Swing bolt or V-clamp closure for secure and easy access. | ||

| Surface Finish | Polished, Pickled/Passivated (internal and external) for enhanced corrosion resistance and hygiene. | ||

| Drain/Vent Ports | Equipped with bottom drain and top vent ports for easy operation and maintenance. | Flow Rate Capacity | High flow rate capacity; varies significantly based on housing size and filter bag micron rating (e.g., from 10 m³/hr to 200+ m³/hr). |

| Design Standard | Designed and manufactured to relevant industry standards (e.g., ASME for pressure vessels, upon request). |

Applicable Industry

The STARK Bag Filter Concave Cover Single Bag Filter is a versatile and highly effective solution for liquid clarification across a broad spectrum of industries. Its high flow rate, large dirt-holding capacity, and robust construction make it indispensable for:

- Water Treatment: Ideal for pre-filtration in various stages, protecting downstream equipment like RO systems, UV sterilizers, and ion exchange resins from suspended solids, sediment, and larger particles in municipal, industrial, and wastewater applications.

- Food & Beverage Industry: Used for clarification of process water, filtration of syrups, edible oils, juices, beer, wine, and removal of impurities from liquid ingredients, ensuring product clarity, safety, and taste.

- Chemical Processing: Filters various chemicals, solvents, resins, and paints to remove particulates, ensuring product purity, protecting pumps, and preventing clogging of spray nozzles or production lines.

- Pharmaceuticals & Biotechnology: Applied in non-critical pre-filtration stages for process water, active pharmaceutical ingredients (APIs), and fermentation broths, safeguarding more stringent downstream filters and processes.

- Oil & Gas Industry: Used for filtration of produced water, injection water, completion fluids, lubricants, and fuels to protect pumps, injectors, and maintain fluid integrity.

- Power Generation: Filters cooling tower make-up water, boiler feed water pre-treatment, and condensate polishing to prevent scaling, corrosion, and improve efficiency.

- Automotive Industry: Filtration of paints, coatings, plating baths, and wash waters to ensure high-quality finishes and prevent defects.

- Textile Industry: Filters dyeing solutions, printing inks, and process water to prevent imperfections in fabrics and ensure consistent color application.

- Cosmetics & Personal Care: Used for the clarification of ingredients, purified water, and final products to ensure visual appeal, stability, and sterility.

- Electronics Manufacturing: Pre-filtration for ultra-pure water systems to remove larger particles, protecting finer filters and sensitive components.

Advantage One

Advantage 1: Superior Dirt-Holding Capacity & Extended Service Life

The STARK Bag Filter with its Concave Cover design excels in applications with high levels of suspended solids, thanks to its exceptional dirt-holding capacity. This means that each filter bag can capture a substantial amount of impurities before requiring replacement, leading to significantly longer service intervals compared to many other filtration types. Extended service life translates directly into reduced operational downtime, lower labor costs associated with frequent change-outs, and a minimized consumption of replacement filter media. This makes our **bag filter** system a highly economical and efficient choice for continuous industrial and commercial operations seeking to optimize their filtration processes and reduce overall maintenance burdens.Advantage TWO

Advantage 2: Robust Construction & Absolutely Sealed Performance

Our STARK Bag Filter is engineered for maximum reliability and operational integrity, featuring robust stainless steel construction and an **absolutely sealed design**. The high-strength stainless steel (SUS304 or SUS316) ensures outstanding resistance to corrosion, chemical exposure, and high pressures, guaranteeing the filter’s longevity and performance in even the most demanding industrial environments. Crucially, the unique concave cover design and precision sealing mechanism prevent any bypass of unfiltered liquid, ensuring that 100% of the fluid passes through the filter bag. This leak-proof performance safeguards downstream equipment from contamination, ensures consistent filtrate quality, and provides complete peace of mind, minimizing the risk of product defects or system damage.Related Products

Produtos Relacionados

- Caixa do filtro de cartucho

Stark Stainless Steel Air Filter Housing for Water Treatment

Adicionar ao orçamento

FAQ

Q1: How long does the reverse osmosis system last?

The lifespan of a reverse osmosis system depends on water quality and maintenance. Typically, the membrane lasts 2–3 years, while the system itself can last over 10 years with proper care.

Q2: Can the system be customized based on different water conditions?

Yes, all our systems are fully customizable. We analyze your water report and application needs before providing tailored solutions.

Q3: What standards does STARK equipment comply with?

Our products comply with CE, ISO 9001, and can be designed to meet specific regional regulations or industry standards upon request.

Q4: What is the delivery time for STARK RO systems?

Standard systems are shipped within 7–15 days. For customized orders, lead time may extend to 20–25 days depending on complexity.

Q5: Do you provide technical support or installation guidance?

Yes. We provide full technical documentation, remote guidance via video, and can dispatch engineers internationally upon request.

Q6: What is included in your quotation?

Our quotation includes the full RO system, control panel, pumps, pre-treatment units, and all necessary fittings. Installation tools and spare parts can be included upon request.