multi cartridge filter

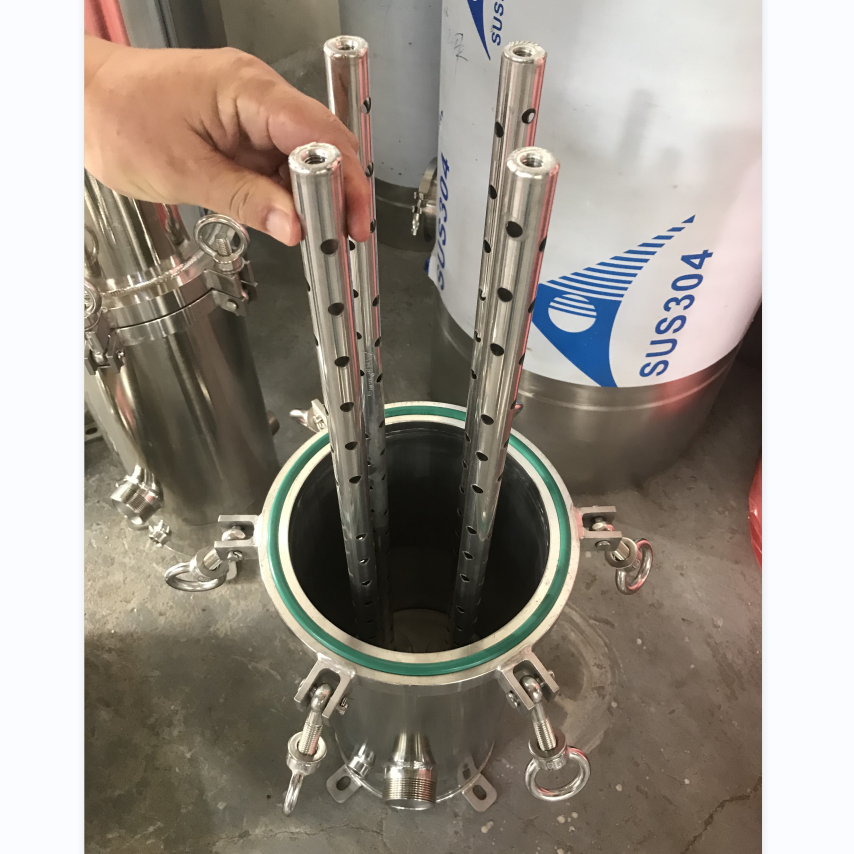

Achieve high-flow, high-precision filtration with Stark Water’s multi cartridge filter. This robust filtration housing accommodates multiple filter elements, ensuring extended service life and efficient removal of particulates for large-scale industrial and commercial water treatment applications.

Product Description

For industrial and commercial operations that demand high flow rates and continuous, precise filtration, a single cartridge filter often falls short. The multi cartridge filter system provides a robust and highly efficient solution, designed to handle larger volumes of fluid while maintaining superior filtration quality. Stark Water’s multi cartridge filter is meticulously engineered to ensure extended service life, reduced maintenance, and consistent performance for your critical purification needs.

High-Capacity Filtration with Multi Cartridge Filter Design

The core advantage of a multi cartridge filter lies in its ability to house numerous filter elements within a single vessel. This design significantly increases the effective filtration surface area, enabling the system to process much higher flow rates compared to a single cartridge housing of similar dimensions. This increased surface area also translates directly into a substantially higher dirt-holding capacity. Consequently, our multi cartridge filter requires less frequent change-outs, dramatically reducing operational downtime, labor costs, and the consumption of replacement filter elements. This makes it an ideal choice for continuous processes where uninterrupted operation and cost-efficiency are paramount.

Versatility with Broad Cartridge Compatibility

Our multi cartridge filter housings are designed for exceptional versatility, compatible with a wide array of standard filter cartridge types and micron ratings. Whether your application requires fine particulate removal (e.g., 0.5 micron), clarification, or pre-filtration, you can select the optimal cartridges—such as pleated, melt-blown, or string-wound—to meet your specific filtration objectives. This broad compatibility allows you to tailor the filtration performance precisely to the fluid characteristics and desired purity levels, ensuring efficient removal of suspended solids, sediment, and other impurities from water or process liquids. The robust design of the housing ensures secure sealing of each cartridge, preventing bypass and guaranteeing consistent filtrate quality.

Durable Construction for Industrial Reliability

Built for the rigors of demanding industrial environments, Stark Water’s multi cartridge filter housings are typically constructed from high-grade stainless steel (e.g., SUS304 or SUS316L). This material offers exceptional corrosion resistance, structural integrity, and durability, allowing the system to withstand high operating pressures and continuous flow. The robust construction minimizes the risk of premature filter failure, ensuring a long operational lifespan and reliable performance. Designed for ease of installation and maintenance, these multi cartridge filters provide a dependable and cost-effective solution for various high-volume water and fluid purification applications, safeguarding downstream equipment and enhancing overall process efficiency.

Product Parameter

Stark Water’s multi cartridge filter is engineered for high-capacity, high-precision filtration. Here are its key technical specifications:

| Parameter | Specification / Customization Options |

|---|---|

| Core Keyword Focus | multi cartridge filter design and capabilities. |

| Number of Cartridges | Customizable (e.g., 3, 5, 7, 12, 21, 36, 50, or more elements per housing). |

| Compatible Cartridge Lengths | Standard lengths: 10″, 20″, 30″, 40″ (254mm, 508mm, 762mm, 1016mm). |

| Cartridge Diameter | Standard 2.5″ (slim) or 4.5″ (Jumbo/Big Blue) diameters. |

| Filter Media Material | Compatible with various types: Polypropylene (melt-blown, string wound, pleated), Cellulose, Nylon, Polyester, Glass Fiber. |

| Micron Rating | Available from 0.5 micron (absolute) to 100 micron (nominal or absolute), depending on cartridges used. |

| Material Construction (Housing) | Stainless Steel (SUS304 or SUS316L recommended for corrosion resistance). |

| Design Type | Vertical cylindrical pressure vessel. Quick-open clamp, swing bolt, or bolted flange closures. |

| Inlet/Outlet Connections | Flanged connections (ANSI, DIN, JIS standards), sizes typically from 2″ to 12″ or larger, based on flow rate. |

| Max. Operating Pressure | Typically 0.6 MPa – 1.0 MPa (6 – 10 Bar / 87 – 145 PSI), customizable for higher pressures. |

| Max. Operating Temperature | Up to 95°C (203°F), dependent on filter media and gasket materials. |

| Flow Rate Capacity | High flow capacity; varies significantly based on housing size, number of cartridges, and micron rating (e.g., from 10 m³/hr to 1000+ m³/hr). |

| Dirt-Holding Capacity | Very high, designed for extended service life and reduced change-outs. |

| Surface Finish | Polished, satin, or pickled/passivated for enhanced hygiene and corrosion resistance. |

| Compliance | Designed to meet relevant industry standards (e.g., ASME for pressure vessels, FDA for food-grade materials). |

Applicable Industry

Stark Water’s multi cartridge filter is a highly versatile and essential component for achieving high-volume, precise filtration across a wide spectrum of industrial and commercial sectors. Its high capacity and adaptability make it ideal for:

- Reverse Osmosis (RO) Pre-filtration: Crucial for large-scale RO systems, providing superior pre-filtration that effectively protects sensitive RO membranes from fouling by fine particulates and suspended solids, thereby extending membrane lifespan and reducing cleaning frequency.

- Food & Beverage Industry: Essential for clarifying large volumes of process water, pre-filtration for bottling lines (beer, wine, juices, bottled water), and removal of fine particles from syrups, edible oils, and other liquid food ingredients to ensure product clarity, taste, and safety.

- Pharmaceutical & Biotechnology: Applied in various stages of process water filtration, pre-filtration for sterile filters, and removal of fine particulates from active pharmaceutical ingredients (APIs) and buffer solutions, ensuring high purity and compliance.

- Chemical Processing: Filters large volumes of various chemicals, solvents, resins, and paints to remove fine solid impurities, ensuring product purity and protecting downstream equipment.

- Electronics & Semiconductor Manufacturing: Provides precise filtration for pre-treatment in ultra-pure water (UPW) systems, removing sub-micron particles to prevent defects in sensitive manufacturing processes.

- Power Generation: Filters large volumes of boiler feed water, cooling tower make-up water, and condensate polishing systems, preventing scaling, corrosion, and improving overall plant efficiency.

- Municipal Water Treatment: Used for final polishing of treated drinking water, removing fine particulates before distribution.

- Wastewater Treatment (Tertiary/Polishing): Employed for final polishing of treated industrial or municipal wastewater effluent to remove fine suspended solids before discharge or reuse.

- Oil & Gas Industry: Used for fine filtration of injection water, produced water, and various process fluids to protect pumps, injectors, and maintain fluid integrity.

- Cosmetics & Personal Care: For high-volume filtration of ingredients, purified water, and final products to ensure clarity, stability, and sterility.

Advantage One

Advantage TWO

Related Products

Похожие товары

FAQ

Q1: How long does the reverse osmosis system last?

The lifespan of a reverse osmosis system depends on water quality and maintenance. Typically, the membrane lasts 2–3 years, while the system itself can last over 10 years with proper care.

Q2: Can the system be customized based on different water conditions?

Yes, all our systems are fully customizable. We analyze your water report and application needs before providing tailored solutions.

Q3: What standards does STARK equipment comply with?

Our products comply with CE, ISO 9001, and can be designed to meet specific regional regulations or industry standards upon request.

Q4: What is the delivery time for STARK RO systems?

Standard systems are shipped within 7–15 days. For customized orders, lead time may extend to 20–25 days depending on complexity.

Q5: Do you provide technical support or installation guidance?

Yes. We provide full technical documentation, remote guidance via video, and can dispatch engineers internationally upon request.

Q6: What is included in your quotation?

Our quotation includes the full RO system, control panel, pumps, pre-treatment units, and all necessary fittings. Installation tools and spare parts can be included upon request.