10T GRP бак ионообменной смолы соли углерода фильтр FRP TANK умягчитель воды системы

Secure large-scale water conditioning with Stark Water’s 10T GRP Tank Water Softener system. This robust GRP tank integrates ion exchange resin with a salt carbon filter, delivering comprehensive water softener treatment for industrial and commercial applications requiring efficient hardness removal and filtration.

Описание товара

For industrial and commercial operations, managing hard water and ensuring the removal of impurities like chlorine and organic compounds are critical for protecting valuable equipment, optimizing processes, and maintaining product quality. The Stark Water 10T GRP Tank Ion Exchange Resin Salt Carbon Filter Water Softener system provides a comprehensive, high-capacity solution designed to address these challenges effectively. This robust system stands as a testament to durability and multi-functional water treatment.

10T GRP Tank: Durable Foundation for Large-Scale Water Treatment

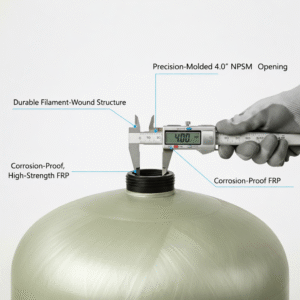

The core of this system is its impressive 10T GRP Tank (Glass Reinforced Plastic), signifying a capacity of 10 tons per hour (10,000 liters per hour or 10 m³/hr) for the overall water softener system. GRP, often synonymous with FRP (Fiber Reinforced Plastic), is a superior composite material chosen for its exceptional properties in demanding water treatment environments:

- Высокая механическая прочность: Capable of withstanding significant operating pressures and continuous industrial use, providing a stable and reliable foundation for large-scale systems.

- Outstanding Corrosion Resistance: Inherently resistant to rust, oxidation, and a wide range of chemicals, acids, and bases, ensuring a significantly longer operational lifespan even with aggressive feedwater or regeneration solutions.

- Lightweight Advantage: Despite its strength, GRP is considerably lighter than steel, facilitating easier transportation and installation, which can reduce overall project costs.

This robust GRP tank ensures the longevity and integrity of your water treatment infrastructure, minimizing the need for frequent replacements and reducing maintenance burdens.

Integrated Ion Exchange Resin & Salt Carbon Filter for Comprehensive Softener Treatment

This STARK system provides a dual-action approach to water treatment, combining advanced softening with effective filtration:

- Ion Exchange Resin for Water Softener System: The primary function involves a high-capacity ion exchange resin housed within the GRP tank. As hard water flows through the resin bed, hardness-causing ions (calcium and magnesium) are exchanged for harmless sodium ions. This process effectively prevents scale buildup in pipes, boilers, cooling towers, and appliances, leading to improved energy efficiency, extended equipment lifespan, and reduced maintenance costs. The system uses a salt tank for automatic regeneration of the resin, ensuring continuous soft water supply.

- Salt Carbon Filter: This component typically refers to an integrated activated carbon filter. While “salt” is used for softener regeneration, the “carbon filter” specifically targets the removal of free chlorine, chloramines, organic compounds, unpleasant tastes, odors, and colors from the water. This is crucial for protecting the ion exchange resin from chlorine degradation and for enhancing the overall palatability and aesthetic quality of the treated water. The carbon filter may or may not share the same regeneration cycle or tank as the softener, but it signifies a comprehensive approach to purification beyond just hardness removal.

This integrated water softener system delivers clean, soft water ideal for a wide array of industrial and commercial processes, optimizing performance and safeguarding assets.

Параметры продукта

The Stark Water 10T GRP Tank Ion Exchange Resin Salt Carbon Filter Water Softener system is engineered for large-scale, comprehensive water conditioning. Here are its key technical specifications:

| Параметр | Спецификация / варианты персонализации |

|---|---|

| Основные ключевые слова | GRP TANK design and capabilities. |

| Тип системы | Automatic Ion Exchange Water Softener System with Integrated Carbon Filter. |

| Nominal Capacity | 10 Tons per Hour (10,000 Liters Per Hour / 10 m³/hr service flow for softener). Custom capacities available. |

| Main Tank Material | GRP TANK (Glass Reinforced Plastic) with high-quality inner liner. |

| Tank Sizes | Typically larger industrial sizes (e.g., diameters 600mm to 1000mm, heights 1800mm to 2500mm), customized for required volume and flow rate. |

| Фильтрующий материал | High-capacity Strong Acid Cation (SAC) Ion Exchange Resin (for softening) and Granular Activated Carbon (GAC) (for carbon filtration). |

| Salt Tank (Brine Tank) | Separate PE (Polyethylene) brine tank, sized for regeneration requirements. |

| Регулирующий клапан | Automatic Multi-port Control Valve (e.g., Runxin, Fleck, Clack equivalent), volume- or time-initiated regeneration, often integrated for both softener and carbon filter backwash. |

| Давление воды на входе | Recommended 0.2 – 0.6 MPa (2 – 6 Bar / 29 – 87 PSI). |

| Температура воды на входе | 5°C - 45°C (41°F - 113°F). |

| Макс. Твердость на входе | Typically up to 450 mg/L (as CaCO³), higher hardness may require larger system sizing. |

| Max. Free Chlorine | < 0.1 ppm after carbon filter. Influent may be higher, handled by carbon filter. |

| Выходные данные Качество воды | Hardness reduced to <0.03 mg/L (as CaCO³); significant reduction of chlorine, taste, odor, and organics. |

| Источник питания | 220V AC, 50/60Hz or 380V AC, 50/60Hz (for automatic control valve and pumps, if applicable). |

| Тип соединения | Flanged connections (ANSI/DIN) for industrial piping. |

| Соответствие требованиям | Designed to relevant industry standards. |

Применимая отрасль

The Stark Water 10T GRP Tank Ion Exchange Resin Salt Carbon Filter Water Softener system is a highly effective and comprehensive solution for managing hard water and improving overall water quality across a broad spectrum of industrial and large-scale commercial sectors. Its robust GRP tank and integrated treatment capabilities make it ideal for:

- Boiler Feed Water Treatment: Crucial for preventing scale formation on heat exchange surfaces in industrial boilers, significantly improving energy efficiency, extending boiler lifespan, and reducing blowdown frequency. The carbon filter protects resin from chlorine.

- Cooling Towers & HVAC Systems: Reduces scale and corrosion in cooling loops, optimizes heat transfer efficiency, minimizes chemical usage for scale control and disinfection, benefiting from both softening and chlorine removal.

- Food & Beverage Industry: Provides softened and filtered process water for product formulation, cleaning-in-place (CIP) systems, and rinse water, preventing mineral precipitation in products/equipment and removing chlorine that could affect taste or product stability.

- Textile & Dyeing Industry: Supplies soft, chlorine-free water for dyeing and washing processes, preventing mineral stains, ensuring consistent color vibrancy, and improving fabric quality.

- Pharmaceutical Industry (Utility Water): Used for general utility water applications where softened and dechlorinated water is required, protecting equipment and maintaining facility hygiene.

- Commercial Laundries: Prevents scale buildup in washing machines, significantly reduces detergent consumption, and improves the softness, cleanliness, and lifespan of fabrics, benefiting from both softening and filtration.

- Hotels & Resorts: Provides soft and filtered water for guest showers, laundries, kitchens, and swimming pools, enhancing guest comfort, extending linen life, and reducing maintenance on facilities and appliances.

- Car Washes & Vehicle Detailing Centers: Ensures spot-free rinsing and enhances cleaning efficiency, reducing chemical usage, and protecting car wash equipment.

- General Industrial Process Water: Provides treated water for a wide array of manufacturing processes where both hardness and chlorine/organic impurities can interfere with product quality or equipment performance.

Преимущество один

Преимущество ДВА

Сопутствующие товары

Похожие товары

- Резервуар для фильтра из стеклопластика

FRP Water Tanks: The Complete Guide & Full Specification List

Подробнее - Резервуар для фильтра из стеклопластика

Stark Commercial High-Flow 4 NPSM Pressure Vessel Series

Подробнее

ЧАСТО ЗАДАВАЕМЫЕ ВОПРОСЫ

Q1: Как долго служит система обратного осмоса?

Срок службы системы обратного осмоса зависит от качества воды и технического обслуживания. Как правило, мембрана служит 2-3 года, а сама система при правильном уходе может прослужить более 10 лет.

Q2: Можно ли настроить систему под различные условия воды?

Да, все наши системы полностью настраиваются. Мы анализируем ваш водный отчет и потребности в применении, прежде чем предложить индивидуальные решения.

Q3: Каким стандартам соответствует оборудование STARK?

Наша продукция соответствует стандартам CE, ISO 9001 и может быть разработана в соответствии с конкретными региональными нормами или отраслевыми стандартами по запросу.

Q4: Каков срок поставки систем обратного осмоса STARK?

Стандартные системы поставляются в течение 7-15 дней. Для индивидуальных заказов срок выполнения может увеличиться до 20-25 дней в зависимости от сложности.

Q5: Предоставляете ли вы техническую поддержку или руководство по установке?

Да. Мы предоставляем полную техническую документацию, удаленное руководство по видеосвязи и можем направить инженеров за границу по запросу.

Q6: Что входит в ваше предложение?

Наше предложение включает в себя полную систему обратного осмоса, панель управления, насосы, блоки предварительной очистки и всю необходимую арматуру. Инструменты для установки и запасные части могут быть включены по запросу.