Резервуар для фильтра из углеродистой стали

Discover robust and cost-effective pre-filtration with Stark Water’s Carbon Steel Filter Tank. Этот прочный carbon steel filter tank is ideal for various industrial water treatment applications, providing reliable removal of suspended solids and impurities before downstream processes.

Описание товара

For many industrial and commercial water treatment applications, efficient and economical pre-filtration is a fundamental requirement to protect downstream equipment and ensure consistent water quality. The Stark Water Carbon Steel Filter Tank offers a highly robust and cost-effective solution for removing suspended solids, sediment, and other particulates from various water sources. This durable filter tank is an essential component in a multi-stage filtration system, designed for long-term, reliable performance in demanding environments.

Durable Carbon Steel Construction for Industrial Applications

The primary advantage of this filter tank lies in its construction from **carbon steel**. This material provides exceptional mechanical strength and durability, making it ideal for large-volume industrial applications where robustness and resistance to high pressures are critical. Carbon steel tanks are particularly well-suited for high-flow filtration systems and can withstand harsh operational conditions. Each tank is meticulously fabricated and typically finished with a protective coating (e.g., epoxy paint, internal lining) to enhance its corrosion resistance, especially when storing or processing raw water. This ensures a long operational lifespan and reliable performance, contributing to the overall integrity of your water treatment infrastructure.

Versatile Media Filtration Capabilities

Сайт carbon steel filter tank is designed to house various filtration media, making it highly versatile for different purification needs. Common configurations include:

- Multi-Media Filters: Utilizes layers of various granular media such as sand, gravel, and anthracite to effectively remove suspended solids, turbidity, and sediment. This is a common and highly effective method for pre-treatment.

- Activated Carbon Filters: Filled with granular activated carbon (GAC), these tanks are excellent for removing chlorine, chloramines, organic compounds, unpleasant tastes, and odors from water.

- Iron & Manganese Removal Filters: Specialized media can be used to oxidize and remove dissolved iron and manganese, preventing staining and buildup.

This adaptability allows the tank to be customized to address specific raw water challenges, ensuring optimal preparation of water before it proceeds to more sensitive purification stages like RO, UF, or ion exchange systems. Its design ensures efficient backwashing, allowing for easy cleaning and regeneration of the filter media, thereby maintaining consistent filtration performance.

Essential for Downstream Equipment Protection

By effectively removing particulates and other contaminants, the Stark Water Carbon Steel Filter Tank plays a crucial role in safeguarding expensive downstream water treatment equipment. This pre-filtration step prevents clogging, fouling, and abrasion of sensitive components such as pumps, membranes (RO, UF), and resin beds (ion exchange), significantly extending their operational lifespan and reducing maintenance costs. Its robust design and efficient filtration contribute directly to the overall efficiency, reliability, and cost-effectiveness of your entire water treatment plant.

Параметры продукта

| Параметр | Спецификация / варианты персонализации |

|---|---|

| Основные ключевые слова | Резервуар для фильтра из углеродистой стали дизайн и возможности. |

| Материал конструкции | High-strength Carbon Steel (A3, Q235B, Q345R or equivalent). |

| Internal Lining (Optional/Recommended) | Food-grade epoxy lining, rubber lining, or other corrosion-resistant coatings for enhanced durability and specific applications. |

| Filter Media Compatibility | Multi-Media (Sand, Gravel, Anthracite), Activated Carbon, Manganese Greensand, Birm, Resin, etc. |

| Тип конструкции | Vertical or Horizontal, Cylindrical Pressure Vessel. |

| Capacity / Diameter | Customizable, wide range of diameters (e.g., 600mm to 3000mm or more) and heights, based on required flow rate and media volume. |

| Входные/выходные соединения | Фланцевые соединения (стандарты ANSI, DIN, JIS), размеры, как правило, от 2″ до 12″ и более, в зависимости от расхода. |

| Макс. Рабочее давление | Typically 0.6 MPa (6 Bar / 87 PSI) to 1.0 MPa (10 Bar / 145 PSI), customizable for higher pressures. |

| Макс. Рабочая температура | Up to 80°C (depending on lining material). |

| Valves & Piping | Manual multi-port valve, automatic diaphragm/butterfly valves, or pneumatic/electric actuated valves for backwash/rinse cycles. UPVC, Carbon Steel, or Stainless Steel piping. |

| Люки/лазы | Top and/or side manholes for media loading/unloading and inspection. |

| Тип поддержки | Skirt support or saddle supports (for horizontal tanks). |

| Surface Finish (External) | Primer + Anti-corrosive paint coating (various colors available). |

| Испытания и сертификация | Hydrostatic testing; ASME U stamp, PED, CE upon request for pressure vessel compliance. |

Применимая отрасль

- Промышленные водоочистные установки: Serving as multi-media filters (sand filters) and activated carbon filters for primary removal of suspended solids, turbidity, chlorine, and organic matter, protecting downstream RO systems, UF systems, and ion exchange resins.

- Выработка электроэнергии: Critical for pre-treatment of boiler feed water, cooling tower make-up water, and general utility water, preventing scaling and corrosion in expensive heat exchange equipment.

- Municipal Water Treatment: Used for filtration of raw surface or well water prior to main disinfection and distribution, improving water clarity and reducing load on subsequent stages.

- Пищевая промышленность и производство напитков: Filters process water for production, cleaning-in-place (CIP) systems, and pre-filtration for ingredient water, ensuring clarity and quality.

- Химическая обработка: Filters process water, wastewater streams, and various chemical solutions to remove particulates and impurities, protecting pumps and ensuring product quality.

- Текстильная и красильная промышленность: Provides pre-filtered water for dyeing and washing processes, preventing imperfections and ensuring consistent product quality.

- Горнодобывающая и металлургическая промышленность: For filtration of process water, washdown water, and wastewater containing heavy suspended solids, crucial for environmental compliance and operational efficiency.

- Очистка и повторное использование сточных вод: Used as primary physical filters to reduce suspended solids in industrial or municipal wastewater streams before further biological or chemical treatment.

- Нефтегазовая промышленность: Filters produced water, injection water, and various process fluids to protect pumps, injectors, and maintain system integrity.

- HVAC & Cooling Systems: Removes suspended solids from circulating water in large chiller and cooling tower systems to improve heat exchange efficiency and prevent clogging.

Преимущество один

Преимущество ДВА

Сопутствующие товары

Похожие товары

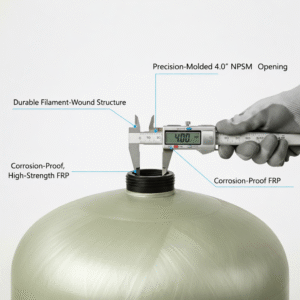

- Резервуар для фильтра из стеклопластика

Stark Industrial 6″ Flange Pressure Vessel Series (Heavy Duty)

Подробнее - Резервуар для фильтра из стеклопластика

Stark Commercial High-Flow 4 NPSM Pressure Vessel Series

Подробнее

ЧАСТО ЗАДАВАЕМЫЕ ВОПРОСЫ

Q1: Как долго служит система обратного осмоса?

Срок службы системы обратного осмоса зависит от качества воды и технического обслуживания. Как правило, мембрана служит 2-3 года, а сама система при правильном уходе может прослужить более 10 лет.

Q2: Можно ли настроить систему под различные условия воды?

Да, все наши системы полностью настраиваются. Мы анализируем ваш водный отчет и потребности в применении, прежде чем предложить индивидуальные решения.

Q3: Каким стандартам соответствует оборудование STARK?

Наша продукция соответствует стандартам CE, ISO 9001 и может быть разработана в соответствии с конкретными региональными нормами или отраслевыми стандартами по запросу.

Q4: Каков срок поставки систем обратного осмоса STARK?

Стандартные системы поставляются в течение 7-15 дней. Для индивидуальных заказов срок выполнения может увеличиться до 20-25 дней в зависимости от сложности.

Q5: Предоставляете ли вы техническую поддержку или руководство по установке?

Да. Мы предоставляем полную техническую документацию, удаленное руководство по видеосвязи и можем направить инженеров за границу по запросу.

Q6: Что входит в ваше предложение?

Наше предложение включает в себя полную систему обратного осмоса, панель управления, насосы, блоки предварительной очистки и всю необходимую арматуру. Инструменты для установки и запасные части могут быть включены по запросу.