Промышленное умягчение воды и деминерализующее оборудование Dia 200*1100mm ионообменная смола соль бак умягчитель воды система 500l в час фильтрации завод

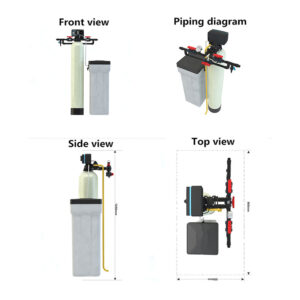

Achieve optimal water quality for your industrial needs with Stark Water’s Industrial Water Softening and Demineralizing Equipment. This compact 500L per hour filtration plant, featuring a Dia 200*1100mm ion exchange resin tank and integrated salt tank, efficiently removes hardness and minerals, protecting your systems and enhancing operational efficiency.

Описание товара

For industrial operations, the quality of water used is a critical factor impacting equipment lifespan, energy efficiency, and product consistency. Hard water and high mineral content can lead to costly scaling, corrosion, and reduced performance in boilers, cooling towers, and process lines. The Stark Water Industrial Water Softener and Demineralizing Equipment offers a robust and highly efficient solution, providing consistently softened and demineralized water essential for various industrial applications.

Dual-Action Purification: Softening and Demineralization

This advanced system combines two crucial water treatment processes:

- Water Softening: The primary function is to effectively remove hardness-causing ions like calcium and magnesium through ion exchange. As raw water passes through the specialized resin within the **Dia 200*1100mm ion exchange resin tank**, these hardness ions are exchanged for sodium ions, preventing scale buildup in pipes, heat exchangers, and machinery. This ensures smoother operations, reduced maintenance, and extended equipment life.

- Demineralization (Optional/Complementary): While primarily a softener, the “Demineralizing Equipment” in its name suggests its capability or potential for significant mineral reduction. Full demineralization typically involves both cation and anion exchange resins (or mixed-bed resin) to remove all dissolved mineral salts, producing deionized water. For simpler applications, the softening process significantly reduces a major portion of dissolved minerals (hardness), contributing to a demineralizing effect. If full demineralization is required, additional resin tanks would be incorporated into the system design, ensuring ultra-pure water.

The system’s efficient design supports a continuous flow of **500L per hour**, making it suitable for small to medium-scale industrial processes requiring a reliable supply of treated water.

Compact Design with Integrated Salt Tank

Designed for industrial practicality, this water treatment plant is built with a compact footprint, allowing for flexible installation even in space-constrained environments. A key feature is the integrated **salt tank**, which simplifies the regeneration process. This tank holds the salt (sodium chloride) required to create the brine solution, which periodically recharges the ion exchange resin, ensuring continuous softening and demineralization performance. The robust construction, typically featuring durable FRP tanks and high-quality components, guarantees longevity and reliability in demanding industrial settings.

Automated Operation for Industrial Efficiency

This industrial water softener is designed for automated operation, minimizing manual intervention and optimizing efficiency. Equipped with intelligent control valves, it can be programmed for automatic regeneration cycles (either time-based or volume-based), ensuring that the resin is always ready to treat water without constant oversight. This automation reduces labor costs, ensures consistent water quality, and prevents downtime, allowing your industrial operations to run smoothly and uninterrupted.

Параметры продукта

The Stark Water industrial water softener and Demineralizing Equipment is engineered for efficient and reliable water treatment in industrial settings. Here are its key technical specifications:

- Емкость для чистой воды: 500 Liters per Hour (LPH) / Approximately 2.2 Gallons per Minute (GPM)

- System Type: Automatic Industrial Water Softener (Ion Exchange principle), with significant demineralizing effect for hardness. Full demineralization (DI water) requires additional resin beds.

- Ion Exchange Resin Tank: Dia 200*1100mm (Diameter 200mm, Height 1100mm) for the primary resin column (typical dimensions; actual may vary by exact model and capacity).

- Resin Type: High-capacity Strong Acid Cation Exchange Resin (for softening). For full demineralization, Strong Base Anion resin or Mixed Bed resin would be added.

- Salt Tank: Integrated Brine Tank (for salt storage and brine solution preparation).

- Control Valve: Automatic Multi-port Control Valve (e.g., Runxin, Fleck, Clack equivalent), volume or time-based regeneration.

- Требования к входной воде:

- Pressure: 0.2 – 0.6 MPa (2 – 6 Bar / 29 – 87 PSI)

- Temperature: 5°C – 45°C

- Hardness: Typically up to 450 mg/L (as CaCO³), higher requires larger system sizing.

- Free Chlorine: <0.1 ppm (pre-treatment may be required).

- Качество воды на выходе: Hardness reduced to <0.03 mg/L (as CaCO³), often with significant reduction in other dissolved solids.

- Источник питания: 220V AC, 50Hz/60Hz (standard for control valve; customizable).

- Connection Type: Threaded (NPT/BSPT) or Flanged connections, suitable for industrial piping.

- Материал конструкции:

- Pressure Tanks: FRP (Fiber Reinforced Plastic), Dia 200*1100mm or larger depending on exact flow.

- Salt Tank: PE (Polyethylene).

- Трубопровод: UPVC или нержавеющая сталь.

- Frame: Optional, often compact standalone tanks.

- Размеры (приблизительно): Varies based on specific configuration, but designed to be compact.

- Filtration Plant: Refers to the overall system including the softener, making it a complete treatment solution.

Применимая отрасль

The Stark Water industrial water softener and Demineralizing Equipment is an indispensable solution for any industrial or commercial operation where hard water or high mineral content can impede efficiency and damage equipment. Its ability to deliver high-quality softened and significantly demineralized water makes it ideal for a diverse range of sectors:

- Boiler Feed Water Treatment: Crucial for preventing scale formation on heat exchange surfaces in industrial boilers, significantly improving energy efficiency, extending boiler lifespan, and reducing blowdown frequency.

- Градирни и системы отопления, вентиляции и кондиционирования воздуха: Reduces scaling and corrosion in cooling loops, optimizing heat transfer efficiency, minimizing chemical usage, and lowering maintenance costs.

- Обработка продуктов питания и напитков: Provides softened process water for product formulation, cleaning-in-place (CIP) systems, and rinse water, preventing mineral precipitation in products and equipment.

- Текстильная и красильная промышленность: Supplies soft water for dyeing and washing processes, preventing mineral stains, ensuring consistent color vibrancy, and improving fabric quality.

- Pharmaceutical Industry (Utility Water): Used for general utility water applications where softened or demineralized water is required, protecting equipment and maintaining hygiene.

- Car Washes & Commercial Laundries: Ensures spot-free rinsing and enhances cleaning efficiency, reduces soap consumption, and extends the lifespan of machinery and textiles.

- Manufacturing & Process Industries: Provides treated water for various production processes, preventing mineral buildup in equipment and ensuring product quality.

- Hospitals & Healthcare Facilities (Non-Critical Areas): Supplies softened water for laundries, dishwashers, and general utility, protecting appliances and ensuring operational efficiency.

Преимущество один

Преимущество ДВА

Сопутствующие товары

Похожие товары

-

системы смягчения воды

Умягчитель воды STARK 4000L SS304 обработка ионная сепарация

Добавить в цитатник

ЧАСТО ЗАДАВАЕМЫЕ ВОПРОСЫ

Q1: Как долго служит система обратного осмоса?

Срок службы системы обратного осмоса зависит от качества воды и технического обслуживания. Как правило, мембрана служит 2-3 года, а сама система при правильном уходе может прослужить более 10 лет.

Q2: Можно ли настроить систему под различные условия воды?

Да, все наши системы полностью настраиваются. Мы анализируем ваш водный отчет и потребности в применении, прежде чем предложить индивидуальные решения.

Q3: Каким стандартам соответствует оборудование STARK?

Наша продукция соответствует стандартам CE, ISO 9001 и может быть разработана в соответствии с конкретными региональными нормами или отраслевыми стандартами по запросу.

Q4: Каков срок поставки систем обратного осмоса STARK?

Стандартные системы поставляются в течение 7-15 дней. Для индивидуальных заказов срок выполнения может увеличиться до 20-25 дней в зависимости от сложности.

Q5: Предоставляете ли вы техническую поддержку или руководство по установке?

Да. Мы предоставляем полную техническую документацию, удаленное руководство по видеосвязи и можем направить инженеров за границу по запросу.

Q6: Что входит в ваше предложение?

Наше предложение включает в себя полную систему обратного осмоса, панель управления, насосы, блоки предварительной очистки и всю необходимую арматуру. Инструменты для установки и запасные части могут быть включены по запросу.