STARK промышленные контейнерные системы очистки воды обратного осмоса контейнерные системы обратного осмоса химической воды

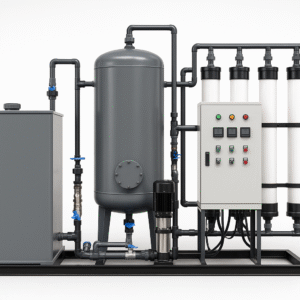

Deploy high-purity water solutions rapidly with Stark Water’s STARK Industrial Containerized RO Purification Systems. This fully integrated containerized chemical water reverse osmosis system offers a pre-assembled, robust, and mobile solution for diverse industrial water treatment needs, ensuring quick setup and reliable performance in any location.

Описание товара

In today’s dynamic industrial landscape, where projects often demand rapid deployment, remote operation, or flexible water supply, traditional fixed-site water treatment plants can pose significant logistical and financial challenges. The Stark Water STARK Industrial Containerized RO Purification Systems offer an innovative and highly efficient solution to these demands. This meticulously engineered system provides a complete, pre-assembled, and mobile water purification plant, ready for immediate operation wherever clean water is needed.

Rapid Deployment with Containerized RO Purification Systems

The defining feature of our Containerized RO Purification Systems is their self-contained design within standard, robust shipping containers (e.g., 20ft or 40ft ISO containers). This revolutionary approach offers unparalleled advantages for various industrial and commercial applications:

- Plug-and-Play Functionality: Systems are factory-assembled, fully piped, wired, and tested before shipment, significantly reducing on-site installation time and costs. Simply connect power, raw water inlet, and purified water outlet, and the system is ready to operate.

- Mobility & Flexibility: Easily transported by truck, rail, or ship to any location, making them ideal for remote sites, temporary projects, emergency relief, or areas with limited infrastructure.

- Защита от стихий: The container provides inherent protection from harsh weather conditions, dust, and unauthorized access, ensuring optimal operating conditions for the equipment and extended lifespan.

- Reduced Civil Works: Minimal need for costly and time-consuming civil construction, allowing for faster project completion.

This innovative design ensures that a high-capacity reverse osmosis purification solution can be rapidly deployed, providing pure water precisely when and where it is needed.

Comprehensive Containerized Chemical Water Reverse Osmosis System

Our industrial containerized RO purification systems are configured as a complete Containerized Chemical Water Reverse Osmosis System, capable of treating a wide range of challenging raw water sources. These systems integrate all necessary stages of purification within the compact container footprint:

- Advanced Pre-treatment: Custom-designed pre-filtration (e.g., multi-media filters, activated carbon, water softeners) and chemical dosing (e.g., anti-scalant, pH adjustment, dechlorination) to protect the RO membranes from fouling and scaling.

- High-Performance RO Unit: Robust reverse osmosis modules with high-rejection membranes and energy-efficient high-pressure pumps to produce pure water from brackish or even seawater (with appropriate SWRO configuration).

- Post-treatment (Optional): Further polishing with UV sterilization, chemical disinfection, or EDI for ultra-pure water applications.

- Автоматизированное управление: A sophisticated PLC-based control system with HMI for fully automatic operation, real-time monitoring, alarm functions, and remote access, ensuring seamless and efficient management.

The “Chemical Water” aspect signifies its capability to handle complex industrial wastewaters or raw waters requiring specific chemical pre-conditioning for optimal RO performance, offering a comprehensive and robust purification solution for various industries.

Параметры продукта

The STARK Industrial Containerized RO Purification Systems are engineered for robust, mobile, and high-performance water purification. Here are their key technical specifications:

| Параметр | Спецификация / варианты персонализации |

|---|---|

| Основные ключевые слова | Containerized RO Purification Systems design and capabilities. |

| Емкость для чистой воды | Customizable, ranging from 1 m³/hr to 100+ m³/hr (approx. 4.4 GPM to 440+ GPM). Large units can be multi-container. |

| Тип контейнера | Standard ISO Shipping Container (e.g., 20ft, 40ft, High Cube). Custom modifications for access, ventilation, and insulation. |

| Совместимость с источником сырой воды | Municipal Water, Well Water, Brackish Water (TDS up to 15,000 ppm), or Seawater (TDS up to 45,000 ppm for SWRO configuration). |

| Тип мембраны обратного осмоса | High-rejection Thin-Film Composite (TFC) RO Membranes (e.g., 8040 series). SWRO membranes for desalination. |

| Integrated Components |

|

| Коэффициент отбраковки соли | ≥98.5% – 99.5% (BWRO); ≥99.5% – 99.7% (SWRO). |

| Коэффициент извлечения воды | 40% – 75% (BWRO); 30% – 50% (SWRO). Dependent on raw water quality and system design. |

| Выходные данные Качество воды | Meets WHO drinking water standards; customized for specific industrial process water needs. |

| Источник питания | 3 Phase, 380V/415V/460V, 50Hz/60Hz (Customizable as per regional standards). Integrated power distribution. |

| Environmental Control | HVAC system for temperature control, insulation, lighting, and ventilation fan within container. |

| Строительный материал |

|

| Mobility | Designed for easy transport and rapid deployment to various locations. |

| Сертификация | Разработаны в соответствии с международными стандартами (например, ISO, CE, ASME, по запросу). |

Применимая отрасль

The STARK Industrial Containerized RO Purification Systems are highly versatile and indispensable solutions for a broad range of industrial, municipal, and commercial sectors requiring flexible, rapidly deployable, and robust water purification. Its integrated and mobile nature makes it ideal for:

- Remote Construction Sites & Camps: Providing a reliable source of potable water and process water in areas without existing infrastructure, easily moved as projects evolve.

- Emergency & Disaster Relief: Rapid deployment of clean drinking water in crisis zones affected by natural disasters, providing immediate access to safe water.

- Mining & Exploration Operations: Supplying process water, utility water, or drinking water in remote mining locations, capable of handling challenging raw water sources.

- Oil & Gas Industry (Onshore/Offshore): Providing treated water for drilling, fracking, camps, or utility water on remote rigs and exploration sites.

- Military & Humanitarian Missions: Offering mobile potable water solutions for troops or affected populations in various operational theaters.

- Temporary Industrial Processes: For industrial facilities that require a temporary increase in purified water supply or for pilot projects at various locations.

- Municipal Water Supply (Expansion/Temporary): Used by municipalities for rapid expansion of water supply, temporary supply during infrastructure repairs, or in remote communities.

- Coastal Industries & Islands: Providing a self-contained seawater desalination solution for industrial use or potable water in areas lacking freshwater access.

- Food & Beverage Manufacturing (Mobile/Pop-up): For on-site purification needs at temporary production facilities or events, ensuring hygiene and product quality.

- Agricultural Projects (Large Scale): Supplying purified water for irrigation or livestock in large agricultural operations, especially when needing to move the water source.

Преимущество один

Преимущество ДВА

Сопутствующие товары

Похожие товары

- Оборудование для очистки сточных вод

Комплексные очистные сооружения STARK для муниципальных и промышленных нужд

Подробнее

ЧАСТО ЗАДАВАЕМЫЕ ВОПРОСЫ

Q1: Как долго служит система обратного осмоса?

Срок службы системы обратного осмоса зависит от качества воды и технического обслуживания. Как правило, мембрана служит 2-3 года, а сама система при правильном уходе может прослужить более 10 лет.

Q2: Можно ли настроить систему под различные условия воды?

Да, все наши системы полностью настраиваются. Мы анализируем ваш водный отчет и потребности в применении, прежде чем предложить индивидуальные решения.

Q3: Каким стандартам соответствует оборудование STARK?

Наша продукция соответствует стандартам CE, ISO 9001 и может быть разработана в соответствии с конкретными региональными нормами или отраслевыми стандартами по запросу.

Q4: Каков срок поставки систем обратного осмоса STARK?

Стандартные системы поставляются в течение 7-15 дней. Для индивидуальных заказов срок выполнения может увеличиться до 20-25 дней в зависимости от сложности.

Q5: Предоставляете ли вы техническую поддержку или руководство по установке?

Да. Мы предоставляем полную техническую документацию, удаленное руководство по видеосвязи и можем направить инженеров за границу по запросу.

Q6: Что входит в ваше предложение?

Наше предложение включает в себя полную систему обратного осмоса, панель управления, насосы, блоки предварительной очистки и всю необходимую арматуру. Инструменты для установки и запасные части могут быть включены по запросу.