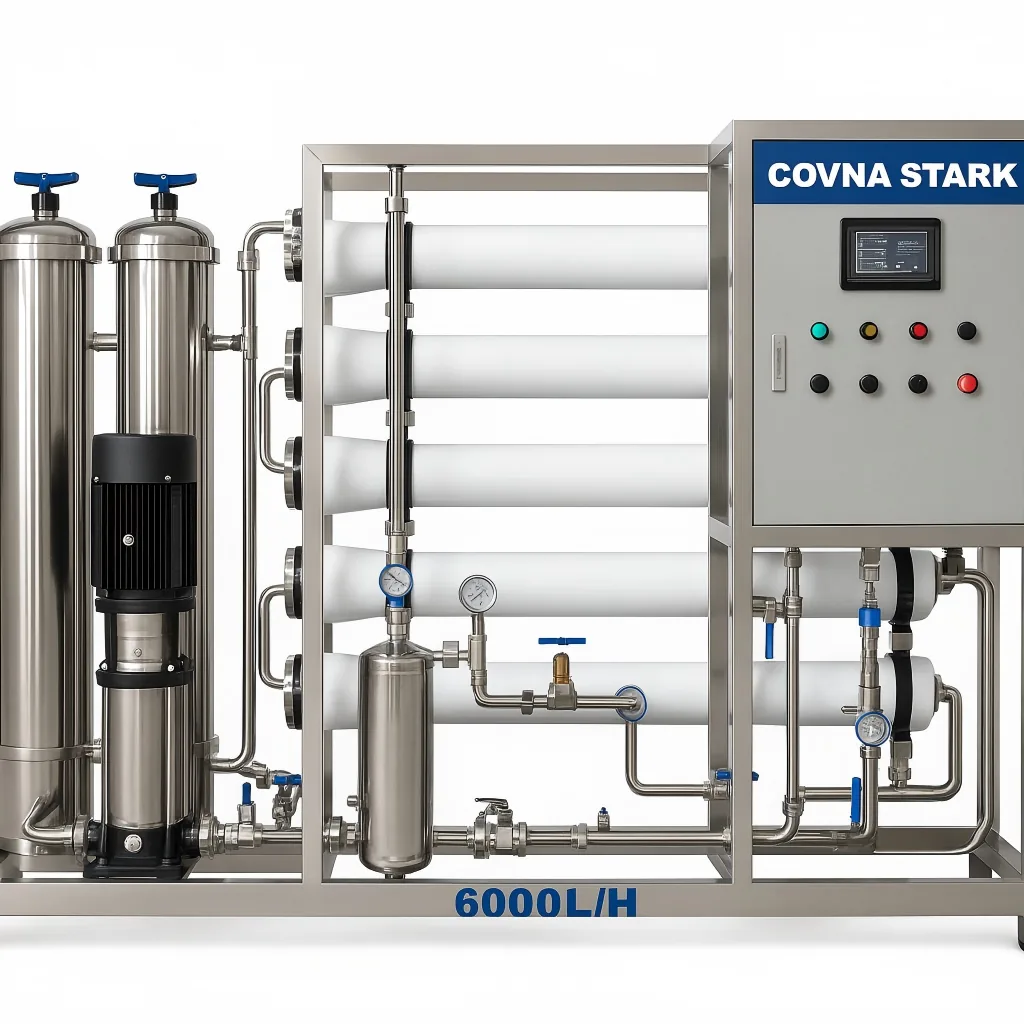

جهاز تنقية المياه بالتناضح العكسي 6000LPH RO لتنقية المياه بالتناضح العكسي، معدات معالجة المياه بالتناضح العكسي مع التحكم PLC

جهاز تنقية المياه بالتناضح العكسي 6000LPH RO لتنقية المياه بالتناضح العكسي، معدات معالجة المياه بالتناضح العكسي مع التحكم PLCجهاز تنقية المياه بالتناضح العكسي 6000LPH RO لتنقية المياه بالتناضح العكسي، معدات معالجة المياه بالتناضح العكسي مع التحكم PLC

6000 LPH RO Water Purification System by STARK delivers stable, low-TDS process water for factories, bottling, and commercial buildings. Skid-mounted design with PLC/HMI, auto-flush, and safety interlocks. Recovery engineered to your feedwater. Request a tailored quote.

Product Description

The 6000 LPH RO Water Purification System is engineered for continuous industrial service. Using reverse osmosis membranes, it removes dissolved salts, organics, and particles to produce consistent permeate for boiler make-up, ingredient water, and rinsing lines. A typical train combines multimedia and activated-carbon filtration, a 5 μm cartridge, a stainless-steel high-pressure pump, and automatic flush cycles to reduce fouling. PLC/HMI control with low-/high-pressure interlocks improves reliability and simplifies daily operation. Standard recovery is 60–65% and can be tuned to your feed TDS, SDI, and scaling index. Options include a VFD high-pressure pump, 2-pass RO or RO+EDI for ultra-low conductivity, UV/ozone post-treatment, a CIP package, and remineralization. The compact, skid-mounted layout reduces footprint and service time—helping you deploy a scalable, energy-aware industrial RO system across plants.

Designed for reliable, 24/7 operation, the STARK 6000 LPH RO system converts municipal or well water into consistently pure process water. A typical process train includes media filtration / activated carbon, cartridge filtration, high-pressure ROو automatic flush sequences to reduce fouling. The compact skid minimizes footprint while providing front-access to pumps, instrumentation, and membranes for fast service.

Why it works: Reverse osmosis uses a semi-permeable membrane to reject dissolved salts, organics, microorganisms, and particulates—delivering permeate that meets downstream needs (boiler makeup, ingredient water, rinsing, etc.). For most industrial sources, 60–65% recovery is a balanced starting point; higher or lower recovery can be engineered based on feed TDS, temperature, SDI, and scaling indices. (STARK provides on-request feedwater testing and sizing.)

Integration & scalability: The system supports options like VFD high-pressure pump, UV/ozone post-treatment, alkalinity re-mineralization, CIP package, or 2-pass RO / EDI when ultra-low conductivity is required. For multi-site rollouts, STARK offers global technical support and spares logistics through our RO product line.

Product Parameter

| Rated Permeate | 6,000 L/h (configurable) |

|---|---|

| Recovery (single-pass) | 60–65% typical; engineered per feed TDS/SDI/LSI |

| Salt Rejection | 96–99% (membrane-dependent) |

| Pretreatment | Multimedia → Activated Carbon → 5 μm cartridge |

| RO Membranes | 4″ or 8″ elements (brand per BOM) |

| High-Pressure Pump | Stainless-steel multistage, VFD optional |

| Control | PLC/HMI, auto-flush, low/high-pressure interlocks |

| Electrical | 380–415 V/50 Hz or 460 V/60 Hz (site standard) |

| Frame & Piping | Stainless-steel skid, SS/UPVC process lines |

Note: Final values are confirmed after feedwater analysis; STARK provides sizing and testing on request.

Applicable Industry

Food & Beverage — ingredient water, CIP make-up

Bottled Water / Beverage — product & rinse water

Pharma / Cosmetics / Lab — pre-polish for DI/EDI

Electronics & Metal Finishing — low-conductivity rinsing

Commercial & Institutional — hospitals, hotels, campuses

Boiler & Cooling Make-Up — scale/corrosion-controlled supply

Advantage One

Advantage 1 — High-Efficiency, Service-Friendly

Compact skid with clear service access

Auto-flush & safety interlocks reduce fouling risk

VFD-ready high-pressure pump for energy optimization

Modular options: CIP, 2-pass, RO+EDI, UV/ozone, remineralization

Advantage TWO

Advantage 2 — Consistent Quality & Expert Support

Stable permeate for critical processes

Engineered recovery to balance water cost vs. fouling

Global spares & remote guidance from STARK

Proven architecture for scalable deployments

Related Products

منتجات ذات صلة

الأسئلة الشائعة

Q1: How long does the reverse osmosis system last?

يعتمد عمر نظام التناضح العكسي على جودة المياه والصيانة. عادةً ما يدوم الغشاء من 2-3 سنوات، بينما يمكن أن يدوم النظام نفسه لأكثر من 10 سنوات مع العناية المناسبة.

Q2: Can the system be customized based on different water conditions?

نعم، جميع أنظمتنا قابلة للتخصيص بالكامل. نقوم بتحليل تقرير المياه الخاص بك واحتياجات التطبيق قبل تقديم حلول مصممة خصيصًا.

Q3: What standards does STARK equipment comply with?

تتوافق منتجاتنا مع معايير CE وISO 9001، ويمكن تصميمها لتلبية لوائح إقليمية أو معايير صناعية محددة عند الطلب.

Q4: What is the delivery time for STARK RO systems?

يتم شحن الأنظمة القياسية في غضون 7-15 يومًا. بالنسبة للطلبات المخصصة، قد تمتد المهلة الزمنية إلى 20-25 يومًا حسب درجة التعقيد.

Q5: Do you provide technical support or installation guidance?

نعم. نحن نقدم وثائق فنية كاملة، وإرشادات عن بُعد عبر الفيديو، ويمكننا إرسال مهندسين دوليًا عند الطلب.

Q6: What is included in your quotation?

Our quotation includes the full RO system, control panel, pumps, pre-treatment units, and all necessary fittings. Installation tools and spare parts can be included upon request.