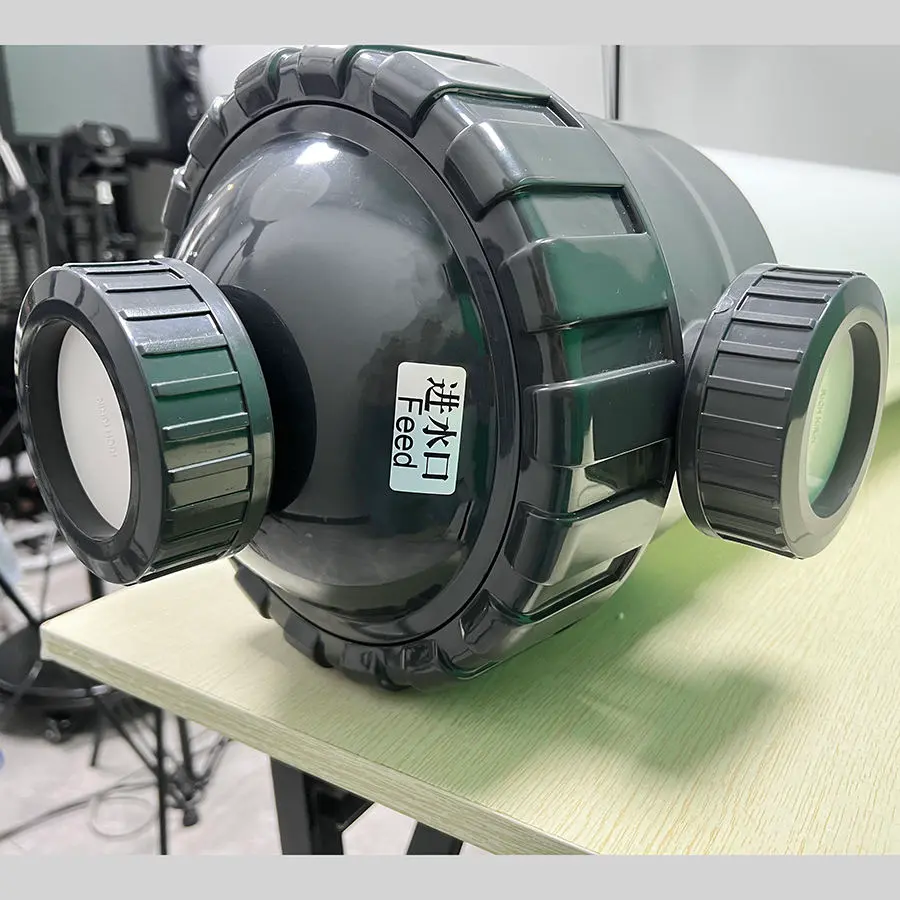

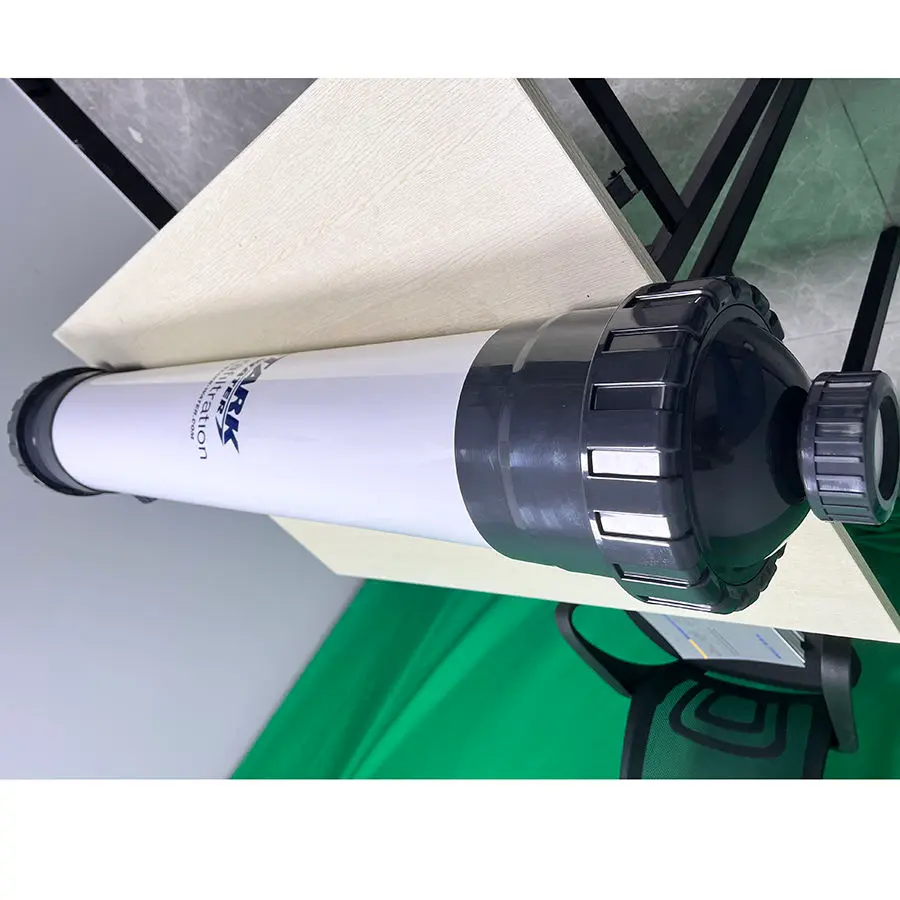

4040 RO Membrane | 4”×40” Reverse Osmosis Element (TFC) | STARK

Note: Final performance depends on feed quality, temperature and operating pressure. We engineer the element selection to your water analysis and pretreatment.

Beschreibung des Produkts

- Stable permeate quality: nominal rejection ≥ 99% on NaCl at 25 °C; smooth surface polyamide for consistent performance.

- Energy flexibility: standard BW elements run ~150–225 psi; LE options target lower pressure at similar flux.

- Serviceability: fits common 4040 vessels; EPDM brine seal; standard 3/4” interconnector ID.

- Designed for pretreatment trains: pair with 20 µm → 5 µm cartridges, carbon/anti-scalant, and UF/clarification as needed to control SDI and biofouling.

Engineering transparency: All ratings are typical and configurable. Guarantees are confirmed against your feed analysis (TDS/SDI, temperature, chlorine, scaling indices) and the selected operating window.

Produkt-Parameter

Technical Parameters (typical values; model-dependent)

| Membrane Type | Thin-Film Composite (TFC) Polyamide |

|---|---|

| Element Size | 4.0″ × 40″ (4040), OD ~3.9″, ID 0.75″ |

| Active Area | ~7.5–8.5 m² (80–90 ft²), depending on model |

| Nominal Salt Rejection | ≥ 99.0% (BW); ≥ 99.2–99.5% for high-rejection variants |

| Typical Permeate Flow | ~2,000–2,800 GPD (7.6–10.6 m³/d) at 25 °C, 2,000 ppm NaCl, pH 7, 15% recovery |

| Betriebsdruck | ~1.0–1.6 MPa (150–225 psi) BW/LE; max 4.1 MPa (600 psi) per model limit |

| Feed Water Temperature | 5–45 °C (flux rises with temperature) |

| pH Range (continuous / cleaning) | 2–11 / 1–13 |

| Free Chlorine Tolerance | 0 mg/L (TFC polyamide is chlorine-sensitive; dechlorinate upstream) |

| Max Feed SDI | < 5 recommended; lower for sensitive duties |

| Max Pressure Drop (per element) | ≤ 1.0 bar (15 psi) |

| Recommended Recovery | 10–20% per pressure vessel (system design-dependent) |

| End Connection | Standard 4040 brine seal and interconnector; EPDM O-rings |

| Available Variants | BW4040 (high rejection), LE4040 (low energy), FR4040 (fouling-resistant), SW4040 (seawater / higher pressure) |

| Test Conditions Note | Unless stated otherwise: 2,000 ppm NaCl, 25 °C, pH 7, 15% recovery; your results vary with temperature and pressure. |

Anwendbare Industrie

- Commercial & light-industrial RO systems for municipal/brackish feeds

- Beverage & bottled water polishing

- Boiler make-up & process water

- Electronics pre-DI / polishing trains

- Wastewater reuse after clarification/UF

- Carwash, HVAC, humidification and rinsing lines

Vorteil Eins

Advantage 1 — High Rejection with Flexible Energy Window

- Nominal ≥ 99% salt rejection on NaCl with stable permeate conductivity.

- Low-energy (LE) options to reduce pump pressure and operating cost.

- Fouling-resistant (FR) construction available for difficult feeds.

Vorteil ZWEI

Advantage 2 — Easy Retrofit & OEM Support

- Compatible with standard 4040 pressure vessels and adapters.

- OEM/Private label available; documentation and QC traceability provided.

- Application engineering: element selection, pretreatment and dosing guidance based on your water analysis.

Verwandte Produkte

Ähnliche Produkte

FAQ

F1: Wie lange hält die Umkehrosmoseanlage?

Die Lebensdauer einer Umkehrosmoseanlage hängt von der Wasserqualität und der Wartung ab. In der Regel hält die Membran 2-3 Jahre, während das System selbst bei richtiger Pflege über 10 Jahre halten kann.

F2: Kann das System an die unterschiedlichen Wasserbedingungen angepasst werden?

Ja, alle unsere Systeme sind vollständig anpassbar. Wir analysieren Ihren Wasserbericht und Ihren Anwendungsbedarf, bevor wir maßgeschneiderte Lösungen anbieten.

F3: Welche Normen erfüllen die STARK Geräte?

Unsere Produkte sind CE- und ISO 9001-konform und können auf Wunsch so gestaltet werden, dass sie spezifischen regionalen Vorschriften oder Industrienormen entsprechen.

F4: Wie lange ist die Lieferzeit für STARK RO Systeme?

Standardsysteme werden innerhalb von 7-15 Tagen ausgeliefert. Bei kundenspezifischen Aufträgen kann sich die Lieferzeit je nach Komplexität auf 20-25 Tage verlängern.

F5: Bieten Sie technische Unterstützung oder Installationshilfen an?

Ja. Wir bieten eine vollständige technische Dokumentation, eine Fernanleitung per Video und können auf Wunsch Techniker ins Ausland schicken.

F6: Was ist in Ihrem Angebot enthalten?

Unser Angebot umfasst die komplette Umkehrosmoseanlage, die Schalttafel, die Pumpen, die Vorbehandlungseinheiten und alle erforderlichen Armaturen. Installationswerkzeuge und Ersatzteile können auf Anfrage mitgeliefert werden.