Ringkasan eksekutif

Does reverse osmosis remove fluoride? Yes. Modern TFC membranes typically remove 85–95%+ when sized and operated in the right window.Reverse osmosis (RO) does remove fluoride effectively. With a modern thin-film composite (TFC) membrane operating in the right window (proper pressure/flux, SDI ≤3, realistic recovery, stable pH), typical rejection is 85–95%+. Actual permeate levels depend on feed concentration, operating set-points and maintenance quality (CIP cadence, cartridge changes, anti-scalant dosing).

Osmosis terbalik can remove most fluoride ions from drinking water when membranes are in good condition and the feed water stays within design limits. In real installations, RO achieves high reduction; always compare permeate levels with WHO 1.5 mg/L dan CDC 0.7 mg/L and verify by testing.

- WHO drinking-water guideline for fluoride: 1.5 mg/L (WHO GDWQ).

- U.S. recommended community water fluoridation level: 0.7 mg/L (CDC recommendations).

How RO removes fluoride (the mechanism)

- Size & charge effects: Fluoride ions are hydrated and larger than the effective membrane pore pathway; TFC membranes also carry surface charge that contributes to ion rejection.

- Driving force: Applied pressure pushes water through the membrane while most dissolved ions—including fluoride—are rejected to concentrate.

- What this means in practice: When the RO is sized and run within vendor limits, you’ll see a large drop in fluoride across the membrane, often bringing permeate down to a small fraction of feed.

Does Reverse Osmosis Remove Fluoride? The Short Answer

These are indicative ranges for brackish/borewell feeds when design & O&M are correct. Always verify with site testing.

- Feed fluoride 0.5–2.0 mg/L → permeate commonly ≤0.1–0.3 mg/L

- Feed fluoride 2-5 mg / L → permeate commonly ≈0.2–0.6 mg/L

- Feed fluoride >5 mg/L → RO still removes a large share, but you may need 2-stage RO or polishing (IX/activated alumina) to hit tight targets

Numbers vary with pressure, temperature, pH, recovery, membrane age, fouling/scaling state and pretreatment quality.

For compliance context, compare your permeate fluoride against the WHO guideline (1.5 mg/L) dan CDC community fluoridation recommendation (0.7 mg/L).

The six things that drive fluoride rejection

- Membrane & flux window

- Use TFC RO elements and keep operating flux within vendor charts; too high raises fouling and can reduce rejection.

- Pressure & temperature

- Adequate net driving pressure improves permeate quality; warmer water lowers viscosity (more flow) but can slightly reduce rejection—adjust set-points seasonally.

- pH control & chemistry

- Keep within the membrane’s recommended pH range. Consistent pH stabilizes rejection and scaling behavior.

- Recovery (don’t over-tighten)

- Push recovery too hard and concentration polarization/scaling increase. Use a realistic recovery and anti-scalant dosing based on your water chemistry.

- Pretreatment quality

- SDI ≤3 (with UF/MMF if needed), chlorine removed (TFC membranes are chlorine-sensitive), and 5 μm cartridge filtration protect the RO surface.

- Maintenance cadence

- Trend conductivity, DP and permeate flow. Trigger CIP by ΔP +15-20%, conductivity drift or normalized flux loss. Correct CIP keeps rejection stable.

Simple design pattern for small municipal/industrial lines

- Skid core: 4040 or 8040 TFC elements sized to your duty cycle (hours/day × days/month) and target flux.

- Pretreatment: MMF/UF → 5 μm cartridge, dechlorination (SMBS if needed), anti-scalant dosing.

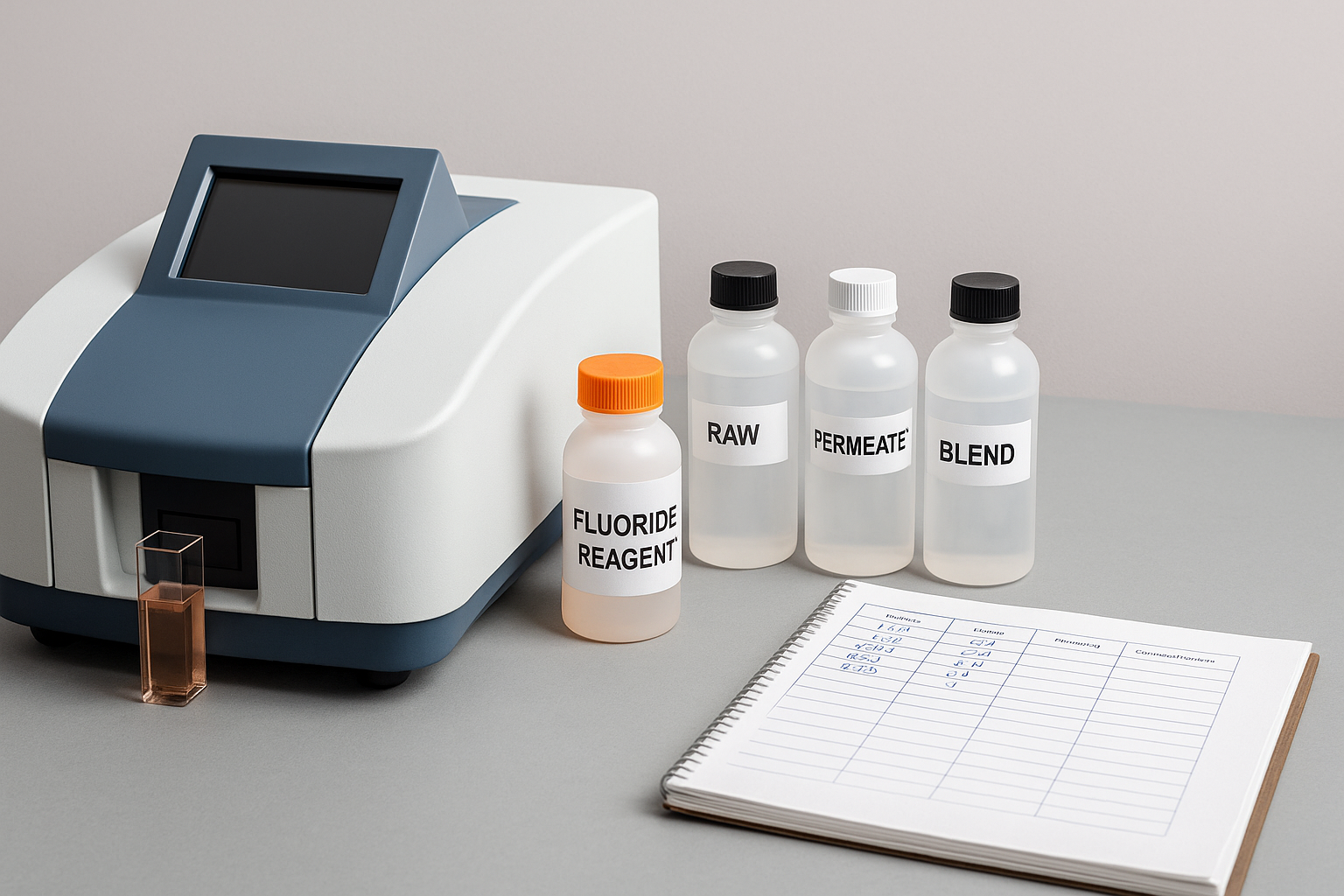

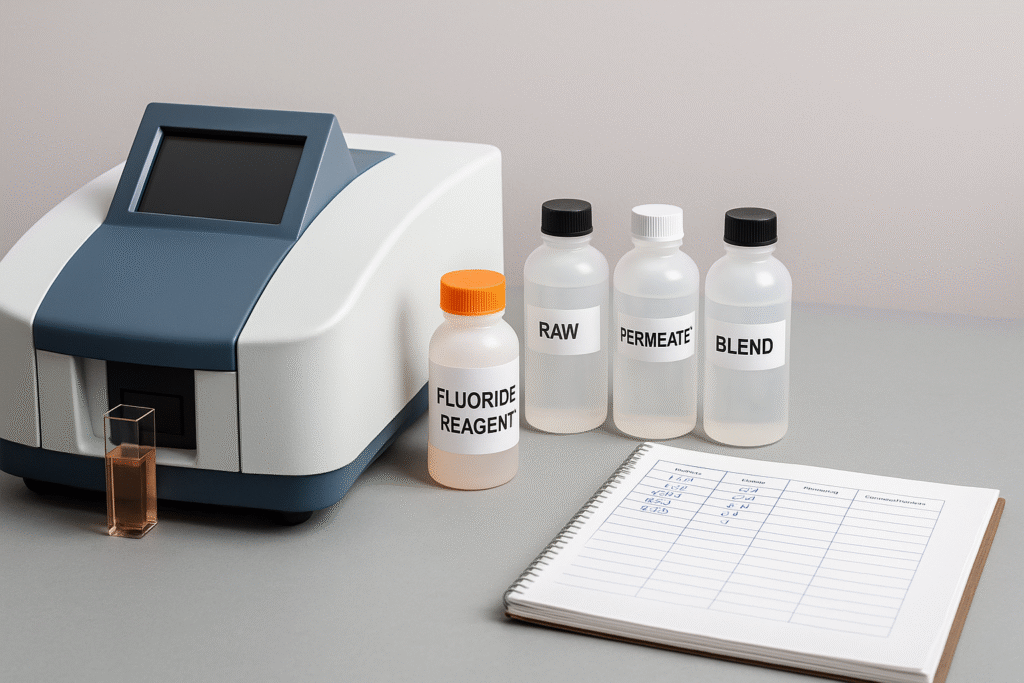

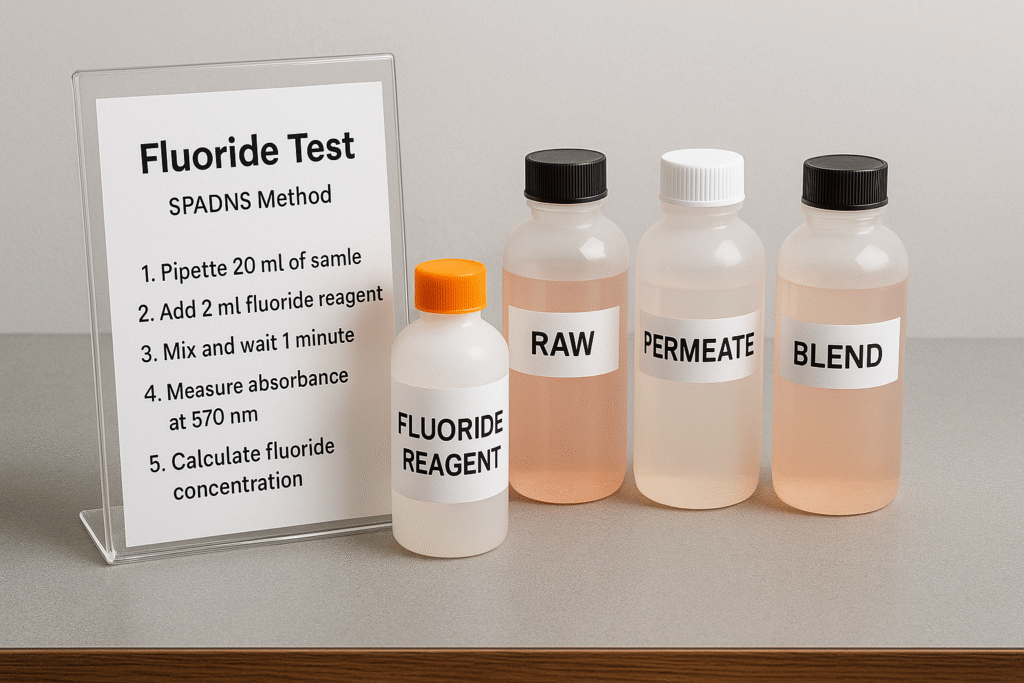

- Kontrol: Online conductivity (feed/permeate), pressure dan flow with trends and alarms; periodic fluoride lab test on feed/permeate to confirm performance.

- Pasca perawatan (if required): Mild remineralization or pH trim for distribution stability and taste.

If you’re scoping a configured package, see your Solusi Pengolahan Air RO 1000 LPH for a reference architecture and KPIs

How to verify removal on your site

- Establish a baseline: Test fluoride on feed and permeate (lab, ISE meter or photometer).

- Operate 2–4 weeks at steady set-points; log conductivity, ΔP and flow.

- Re-test fluoride and compare. Stable or improving trends = healthy membrane & chemistry window.

- If permeate drifts up: check pretreatment (SDI), cartridge filter loading, anti-scalant dose, recovery too high, or CIP due.

RO vs alternative fluoride technologies

- Activated alumina (AA) – Excellent polishing for low permeate targets; needs periodic regeneration; sensitive to pH.

- Ion exchange (IX) – Strong polishing when feeds are moderate; watch competing anions and resin selection.

- Bone char – Works but typically slower and more niche for small flows.

- RO – Broad contaminant reduction (not only fluoride), consistent quality when instrumented and maintained; energy & concentrate handling must be planned.

Hybrid designs are common: RO for bulk reduction + AA/IX polishing when feed is very high or limits are stringent.Bottom line: does reverse osmosis remove fluoride? Yes—reliably, provided the plant is sized correctly, SDI is controlled, and O&M (CIP cadence, cartridge changes and anti-scalant dosing) keep the membrane in its sweet spot. If tap targets are very tight, combine RO with polishing media to reach 0.2–0.6 mg/L.

Tools to help you run the numbers

- Kalkulator RO OPEX (Universal) – Estimate monthly energy/chemicals/filters/CIP & membrane amortization for your duty cycle

- Kalkulator LSI – Check scaling tendency and set recovery/chemistry with confidence

PERTANYAAN YANG SERING DIAJUKAN

Apakah reverse osmosis menghilangkan fluoride?

Yes. Properly sized and maintained RO systems typically remove 85–95%+ of fluoride from brackish/borewell water. Actual results are site-dependent.

Why does my permeate fluoride vary over time?

Changes in recovery, pH, temperature, fouling state or insufficient pretreatment (high SDI) can shift rejection. Trend conductivity and schedule CIP based on ΔP and normalized flux.

Do I need polishing after RO to meet strict limits?

If feed fluoride is high or limits are very tight, add AA or IX polishing after RO to lock in a low residual.

Haruskah saya melakukan remineralisasi air RO?

For distribution stability/taste and to avoid corrosivity, many plants add light remineralization or pH trim post-RO.

Seberapa sering saya harus menguji fluoride?

At commissioning: weekly for 4–6 weeks. In steady state: monthly or per regulation. Always re-test after major set-point changes or CIP.