Pemurni Air RO 6000LPH, Peralatan Pengolahan Air RO dengan Kontrol PLC

Pemurni Air RO 6000LPH, Peralatan Pengolahan Air RO dengan Kontrol PLCPemurni Air RO 6000LPH, Peralatan Pengolahan Air RO dengan Kontrol PLC

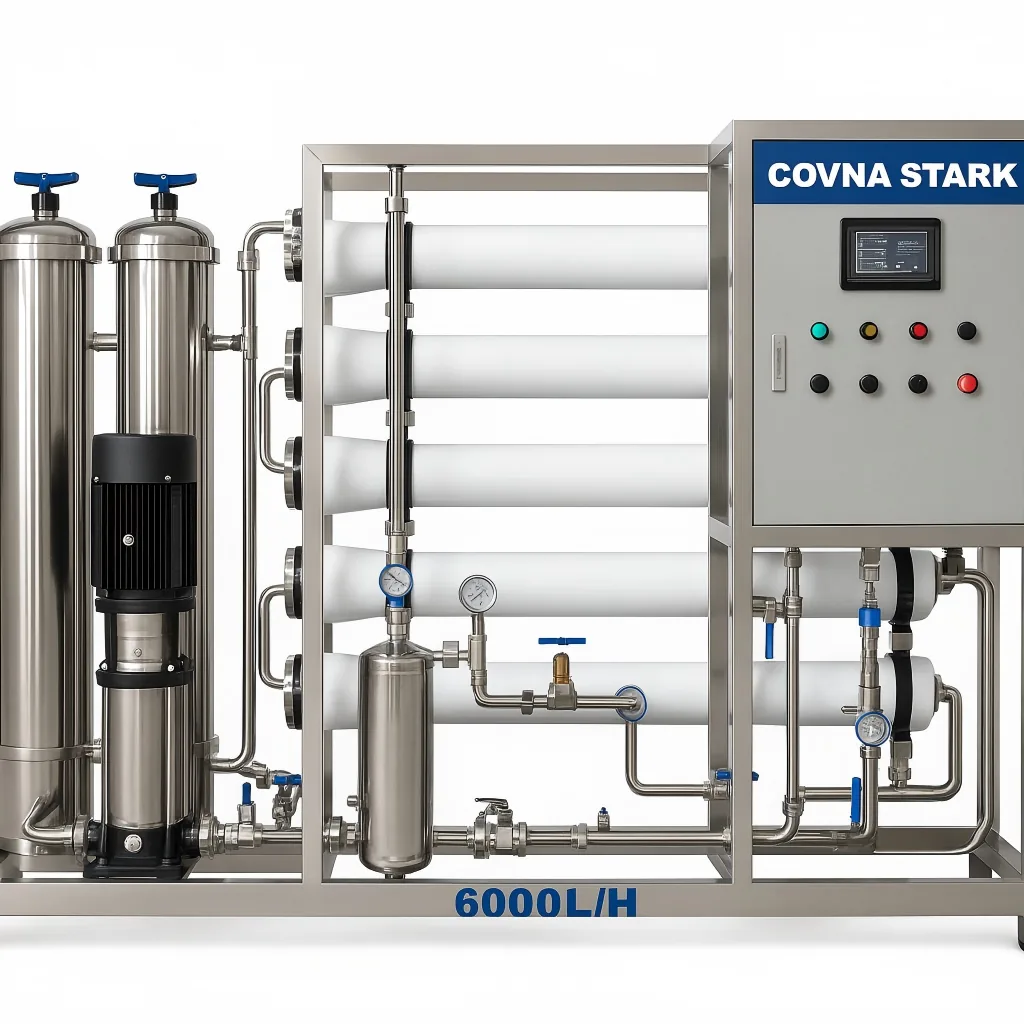

6000 LPH RO Water Purification System by STARK delivers stable, low-TDS process water for factories, bottling, and commercial buildings. Skid-mounted design with PLC/HMI, auto-flush, and safety interlocks. Recovery engineered to your feedwater. Request a tailored quote.

Deskripsi Produk

The 6000 LPH RO Water Purification System is engineered for continuous industrial service. Using reverse osmosis membranes, it removes dissolved salts, organics, and particles to produce consistent permeate for boiler make-up, ingredient water, and rinsing lines. A typical train combines multimedia and activated-carbon filtration, a 5 μm cartridge, a stainless-steel high-pressure pump, and automatic flush cycles to reduce fouling. PLC/HMI control with low-/high-pressure interlocks improves reliability and simplifies daily operation. Standard recovery is 60–65% and can be tuned to your feed TDS, SDI, and scaling index. Options include a VFD high-pressure pump, 2-pass RO or RO+EDI for ultra-low conductivity, UV/ozone post-treatment, a CIP package, and remineralization. The compact, skid-mounted layout reduces footprint and service time—helping you deploy a scalable, energy-aware industrial RO system across plants.

Designed for reliable, 24/7 operation, the STARK 6000 LPH RO system converts municipal or well water into consistently pure process water. A typical process train includes media filtration / activated carbon, cartridge filtration, high-pressure ROdan automatic flush sequences to reduce fouling. The compact skid minimizes footprint while providing front-access to pumps, instrumentation, and membranes for fast service.

Why it works: Reverse osmosis uses a semi-permeable membrane to reject dissolved salts, organics, microorganisms, and particulates—delivering permeate that meets downstream needs (boiler makeup, ingredient water, rinsing, etc.). For most industrial sources, 60–65% recovery is a balanced starting point; higher or lower recovery can be engineered based on feed TDS, temperature, SDI, and scaling indices. (STARK provides on-request feedwater testing and sizing.)

Integration & scalability: The system supports options like VFD high-pressure pump, UV/ozone post-treatment, alkalinity re-mineralization, CIP package, or 2-pass RO / EDI when ultra-low conductivity is required. For multi-site rollouts, STARK offers global technical support and spares logistics through our RO product line.

Parameter Produk

| Rated Permeate | 6,000 L/h (configurable) |

|---|---|

| Recovery (single-pass) | 60–65% typical; engineered per feed TDS/SDI/LSI |

| Salt Rejection | 96–99% (membrane-dependent) |

| Pretreatment | Multimedia → Activated Carbon → 5 μm cartridge |

| RO Membranes | 4″ or 8″ elements (brand per BOM) |

| High-Pressure Pump | Stainless-steel multistage, VFD optional |

| Control | PLC/HMI, auto-flush, low/high-pressure interlocks |

| Electrical | 380–415 V/50 Hz or 460 V/60 Hz (site standard) |

| Frame & Piping | Stainless-steel skid, SS/UPVC process lines |

Note: Final values are confirmed after feedwater analysis; STARK provides sizing and testing on request.

Industri yang Berlaku

Food & Beverage — ingredient water, CIP make-up

Bottled Water / Beverage — product & rinse water

Pharma / Cosmetics / Lab — pre-polish for DI/EDI

Electronics & Metal Finishing — low-conductivity rinsing

Commercial & Institutional — hospitals, hotels, campuses

Boiler & Cooling Make-Up — scale/corrosion-controlled supply

Keuntungan Satu

Advantage 1 — High-Efficiency, Service-Friendly

Compact skid with clear service access

Auto-flush & safety interlocks reduce fouling risk

VFD-ready high-pressure pump for energy optimization

Modular options: CIP, 2-pass, RO+EDI, UV/ozone, remineralization

Keuntungan DUA

Advantage 2 — Consistent Quality & Expert Support

Stable permeate for critical processes

Engineered recovery to balance water cost vs. fouling

Global spares & remote guidance from STARK

Proven architecture for scalable deployments

Produk Terkait

Produk Terkait

- Sistem osmosis terbalik

Pabrik pengolahan air pemurnian desalinasi air sistem osmosis balik 1000L

Tambahkan ke Kutipan

PERTANYAAN YANG SERING DIAJUKAN

T1: Berapa lama sistem reverse osmosis bertahan?

Umur dari sistem reverse osmosis tergantung pada kualitas air dan pemeliharaan. Biasanya, membran bertahan selama 2-3 tahun, sedangkan sistem itu sendiri dapat bertahan lebih dari 10 tahun dengan perawatan yang tepat.

T2: Dapatkah sistem disesuaikan berdasarkan kondisi air yang berbeda?

Ya, semua sistem kami dapat disesuaikan sepenuhnya. Kami menganalisis laporan air dan kebutuhan aplikasi Anda sebelum memberikan solusi yang disesuaikan.

T3: Standar apa yang dipatuhi oleh peralatan STARK?

Produk kami memenuhi CE, ISO 9001, dan dapat dirancang untuk memenuhi peraturan regional atau standar industri tertentu berdasarkan permintaan.

T4: Berapa waktu pengiriman untuk sistem STARK RO?

Sistem standar dikirim dalam waktu 7-15 hari. Untuk pesanan yang disesuaikan, waktu tunggu dapat diperpanjang hingga 20-25 hari tergantung pada kerumitannya.

T5: Apakah Anda menyediakan dukungan teknis atau panduan pemasangan?

Ya. Kami menyediakan dokumentasi teknis lengkap, panduan jarak jauh melalui video, dan dapat mengirimkan teknisi secara internasional berdasarkan permintaan.

T6: Apa saja yang termasuk dalam penawaran Anda?

Kutipan kami mencakup sistem RO lengkap, panel kontrol, pompa, unit pra-perawatan, dan semua perlengkapan yang diperlukan. Alat instalasi dan suku cadang dapat disertakan berdasarkan permintaan.