SWRO 8040 高透過率RO膜

SWRO 8040 高透過率RO膜SWRO 8040 高透過率RO膜

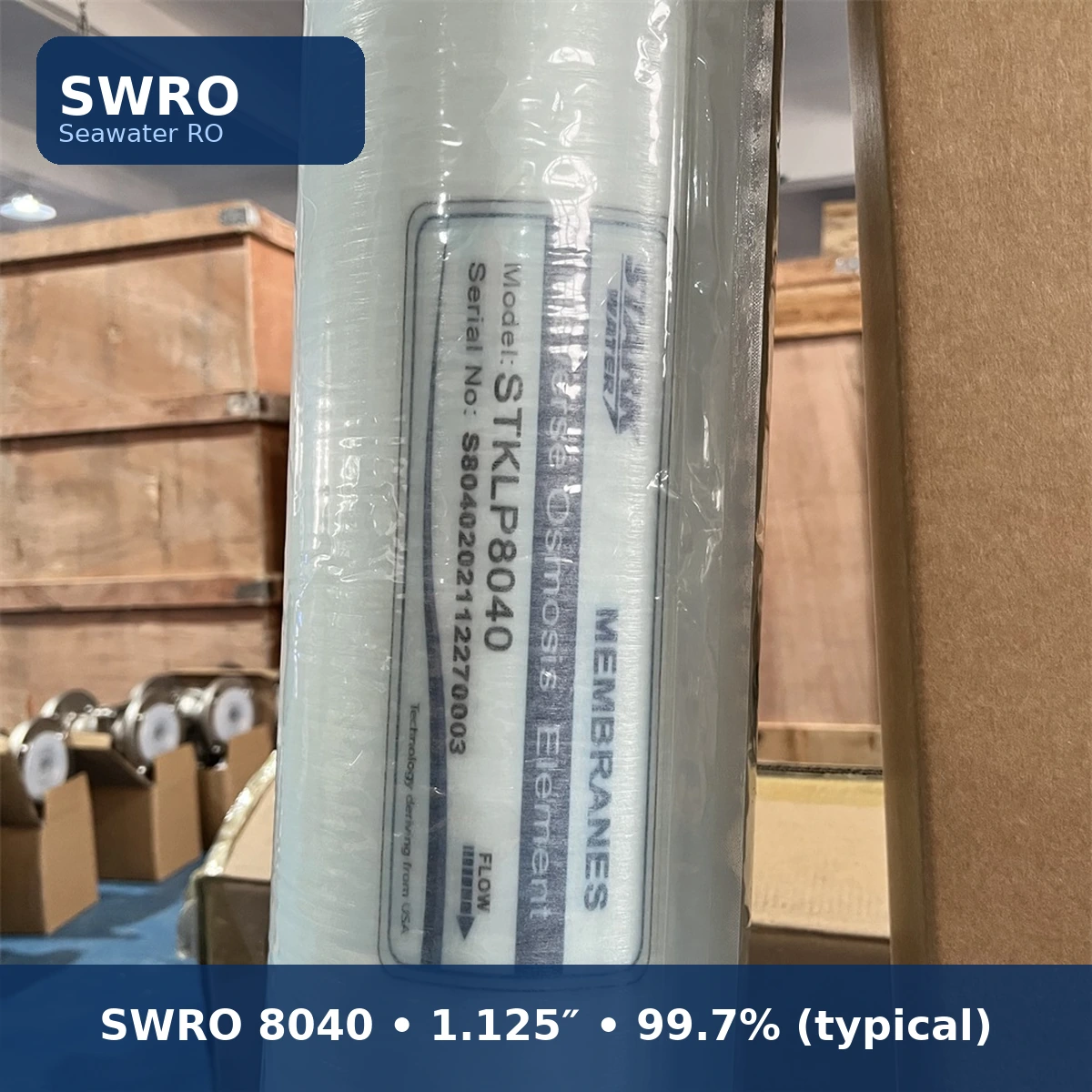

SWRO 8040 high-rejection seawater reverse osmosis membrane for first-pass desalination. Rated around 32,000 mg/L NaCl at 25 °C with typical operating pressure near 800 psi. Typical salt rejection up to 99.7% when pretreatment, recovery, and temperature follow supplier limits.

商品説明

This SWRO 8040 RO membrane is engineered for first-pass seawater desalination, combining high salt rejection with stable flux under standard SWRO test conditions.

This 8.0″ × 40″ thin-film composite (TFC) RO膜 is built for industrial and municipal seawater lines that need high rejection, predictable flux, and compatibility with standard 8040 pressure vessels and interconnectors. It integrates cleanability and preservation guidance so operators can maintain stable product water over the service life.

Key features

- High salt rejection (typical up to 99.7%) for low product conductivity.

- Optimized feed spacer for stable differential pressure and cleaning recovery.

- 1.125″ permeate tube ID; drop-in fit for standard 8040 vessels and couplers.

- Works with staged arrays and energy recovery devices in SWRO trains.

- Supported by approved CIP chemistry そして preservation procedures.

Interfaces & compatibility

- Format: 8040 TFC polyamide element

- Permeate tube: 1.125″ (28.6 mm)

- Vessels/couplers: standard 8″ multi-element pressure vessels with interconnectors

- Change-out: replace like-for-like in most 8040 housings

Operating & cleaning limits*

- Max temperature: 45 °C (113 °F)

- pH range (operation): 2–11; (cleaning): 1–12

- Max pressure: 1,200 psi (8.3 MPa)

- Free chlorine: not recommended on TFC unless the datasheet explicitly allows; dechlorinate upstream

*Always verify the exact limits on the current model datasheet.

Typical test conditions

32,000 mg/L NaCl, 25 °C, ~800 psi, ~8% recovery. In service, performance varies with temperature, salinity, recovery, and pretreatment (SDI/MFI, antiscalant window).

What’s included and Why choose this SWRO 8040 RO membrane

- Factory-preserved element in sealed bag

- Installation & torque notes; cleaning/preservation guidance (download)

Need field criteria? See RO membrane replacement, cleaning & CIPそして troubleshooting matrix.

製品パラメーター

| Element size | 8.0″ × 40″ (8040) |

|---|---|

| Active area | ~37 m² (400 ft²), model dependent |

| Typical salt rejection | up to 99.7% (datasheet dependent) |

| Rated permeate flow (window) | ~28–34 m³/d (7,500–9,000 gpd) @ 32,000 mg/L, 25 °C |

| Permeate tube ID | 1.125″ (28.6 mm) |

| Max operating pressure | 1,200 psi (8.3 MPa) |

| Max temperature | 45 °C (113 °F) |

| pH range | 2–11 operation; 1–12 cleaning |

| Test conditions | 32,000 mg/L NaCl; 25 °C; ~800 psi; ~8% recovery |

Values shown are typical for listing purposes; final selection should follow the current model datasheet.For most retrofits, this swro 8040 ro membrane drops into standard 8″ vessels with 1.125″ permeate tubes.

適用業種

- Seawater desalination (first-pass SWRO) for municipalities

- Coastal hotels, island resorts, marine/offshore watermakers

- Industrial process water where seawater feed requires high rejection

アドバンテージ・ワン

Advantage 1 — High rejection for stable product water

Deliver consistently low product conductivity with robust polyamide selectivity and flow-balanced feed spacers that help control differential pressure across stages.アドバンテージ2

Advantage 2 — Drop-in 8040 compatibility and serviceability

スタンダード 1.125″ permeate tube and multi-element vessel coupling enable fast change-outs in existing housings. Supported by clear acceptance criteria after start-up: normalized permeate flow ≥ 90–100% of the clean baseline, rejection at spec, and stage ΔP within limits.関連商品

関連商品

よくあるご質問

Q1: 逆浸透システムの寿命はどのくらいですか?

逆浸透膜システムの寿命は、水質とメンテナンスに左右されます。通常、膜は2~3年、システム自体は適切な手入れをすれば10年以上持ちます。

Q2: 異なる水質条件に応じてシステムをカスタマイズできますか?

はい、当社のシステムはすべてフルカスタマイズが可能です。お客様のウォーターレポートとアプリケーションのニーズを分析し、オーダーメイドのソリューションを提供します。

Q3: STARKの機器はどのような規格に準拠していますか?

当社の製品はCE、ISO 9001に準拠しており、ご要望に応じて特定の地域の規制や業界標準に適合するように設計することができます。

Q4: STARK ROシステムの納期はどのくらいですか。

標準システムは7~15日以内に出荷される。カスタマイズされた注文の場合、リードタイムは複雑さによって20~25日に延びることがあります。

Q5: 技術サポートや設置指導は行っていますか?

はい。完全な技術文書、ビデオによる遠隔指導を提供し、ご要望に応じてエンジニアを海外に派遣することも可能です。

Q6: 見積もりには何が含まれていますか?

お見積もりには、ROシステム一式、コントロールパネル、ポンプ、前処理ユニット、必要な付属品が含まれます。ご要望に応じて、設置用工具やスペアパーツも含まれます。