what is water pump

A water pump is a machine that transports or pressurizes a liquid. It transfers the mechanical energy of the prime mover or other external energy to the liquid, increasing the liquid energy, and is mainly used to transport liquids including water, oil, acid-base liquid, emulsion, suspoemulsion and liquid metal.

Liquids, gas mixtures and liquids with suspended solids can also be transported. The technical parameters of water pump performance include flow, suction, head, shaft power, water power, efficiency, etc.; according to different working principles, it can be divided into volumetric pumps, vane pumps and other types. Positive displacement pump uses the change of its working chamber volume to transfer energy; vane pump uses the interaction between rotating blades and water to transfer energy, including centrifugal pump, axial flow pump and mixed flow pump.

With many years of professional manufacturing experience.

Real factory,real factory direct sales,saving the cost of middlemen,the price is 10%-15%lower than the competitors.

Complete customer files,regular tracking of equipment operation Respond promptly and solve problems reported by customers.

We have a strong production capacity can ensure rapid delivery at the appointed time.

Related Products

More items about water pump

water pump

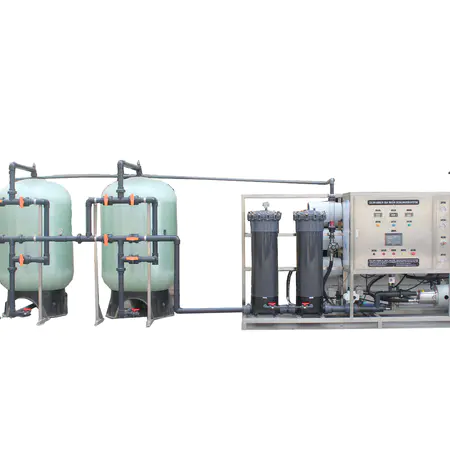

Guangdong Stark Water Treatment Technology Co., Ltd. is a company that focuses on watertreatment plant and is committed to the research and development, production, sales and after-sales service of environmentally friendly water purification industrial products.

The main production and operation of water treatment plant: reverse osmosis system, ultrafiltration system, EDI desalination system, sea water desalination plant, brackish water desalination plant. Products are widely used in electronics, electroplating, power plants, medicine, petroleum, chemical, food and beverage, printing and dyeing indutries. Starck strives to be the forefront explorer of water treatment equipment at home and abroad!

The development trend of water pump

Energy conservation and emission reduction have become the main content of China's economic development plan, especially for power, steel, non-ferrous metals, petrochemicals, water treatment and other industries with high energy consumption, more stringent emission reduction policies have been put forward. As the fluid conveying equipment in the industrial center, the water pump occupies the main part of energy consumption, and it has become the main problem to be solved in the energy saving operation.

The most common way to drive the water pump is to drive it with an electric motor. The energy saving method of the pump is mainly to make the pump unit (pump, prime mover and conversion part) run at the highest power, so that the electric energy consumed by the external input is reduced to the lowest point. The energy saving of the pump is a comprehensive technology, which involves the energy saving of the pump itself, the energy saving of the system and the operation of the application management.

What is the classification of water pump?

Water pumps have different uses, different conveying liquid media, different flow rates, and different lift ranges. Therefore, of course, their structural forms and materials are also different. To sum up, they can be roughly divided into: 1. Urban water supply 2 , sewage system 3, civil engineering, building system 4, agricultural water conservancy system 5, power station system, 6, chemical system 7, petroleum industry system 8, mining and metallurgy system 9, light industry system 10, ship system.

What are the precautions for using the water pump?

1. If the water pump has any small fault, remember not to let it work. If the packing of the water pump shaft is worn out, it should be added in time. If the water pump is continued to be used, air will leak.

2. If the water pump vibrates strongly during use, be sure to stop and check the cause, otherwise it will also cause damage to the pump.

3. The water pump must be maintained after use. For example, when the water pump is used up, the water in the water pump should be cleaned up. It is best to remove the water pipe and rinse it with clean water.

4. The tape on the water pump should also be removed, then rinsed with water and dried in the light. Do not put the tape in a dark and humid place. The tape of the water pump must not be stained with oil, let alone some sticky things on the tape.

User Reviews

What users say about Stark

The quality of the product is very good, as described by the manufacturer, the speed of logistics and freight is very powerful, and a very satisfactory transaction.

John

The manufacturer is very strong, and it is very easy to cooperate, the delivery speed is very fast, and the quality is guaranteed! Looking forward to the next cooperation!

I have understood each other in all aspects before cooperation. It is indeed a very honest manufacturer. The delivery date is accurate. I hope to have further cooperation next time!

Frequently Asked Question

Do you have any question?

Stainless steel products are automatically welded and polished.

Usually 1 year-1.5 years, it depends on the product.

Online solution, if it can’t be solved online, we will send an engineer to solve it on site.

Get In Touch

Don't hesitate to contact us!

- reverse osmosis system

- stainless steel water tank

- water softener

- membrane housing

- ozone generator

- uv sterilizer

- cartridge filter

- frp tank

- filter tank

- water tank

- sea water desalination

- ro membrane

- ultrafiltration equipment

- uf equipment

- water treatment plant

- water treatment

- ro treatment plant

- water purification machine

- ro water system

- pure water equipment

- reverse osmosis water filter

- uf system

- uf membrane

- water pump

- water purification system